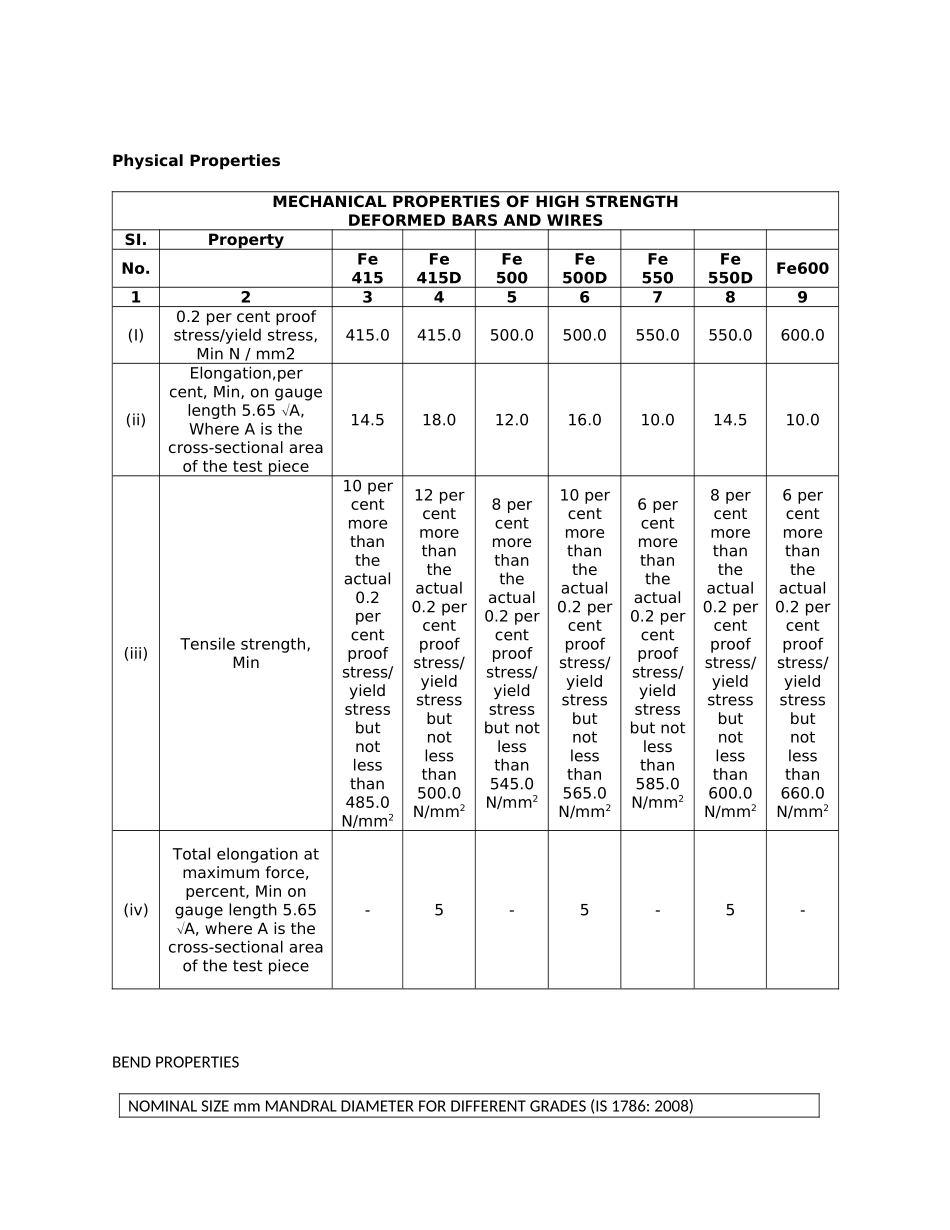

Thermo-mechanicaltreatment(TMT):TMTisanacronymforthephrase‘thermo-mechanicaltreatment’.TheBureauofIndianStandardswhileissuingthenewcodeIS:1786-1985TMTBarsisanacronymfor“thermo-mechanicaltreatment”.ThermoMechanicallyTreated(TMT)barsaremanufacturedusingthe'Quenching&Tempering'(Q&T)technology.TMTbarsgetsitsstrengthpropertiesfromquenchingandtempering.NomechanicaltreatmentisinvolvedinTMTBars.Quenching:HotTMTbarscomingoutfromrollingmillsaretreated(cooled)withwateronthesurfacetoformmartensiteonthesurface,thecoreremainaustenitic.TheTMTsteelbarsarepassedthroughawater-coolingsystemwheretheyarekepttilltheoutersurfaceofthebarsbecomescolderwhilethecoreremainshot.Thiscreatesatemperaturegradientinthebars.Tempcore:TMTBARSareremovedfromcoolingzone.Atemperaturegradientisestablishedinthecrosssection.Itcausesheattoflowfromcentretosurface.Themartensiteleftatcentreistemperedbyheatflow.Soitisknownastempcore.Aftertheintensivecooling,theTMTbarisexposedtoairandthecorereheatsthequenchedsurfacelayerbyconduction,thereforetemperingtheexternalmartensite.Helpsthemattainhigheryieldstrength.Theresultingheat-treatedstructureimpartssuperiorstrengthandtoughnesstothebars.Dependingupontheyieldstrengthandductilityrequiredpercentageoftransformedcoreareaandtemperaturerangesarechosen.IsothermalTransformation:Austeniteremainingatthecoreistransformed.Duringatmosphericcooling,austenitetransformsintoaveryfine-grainedpearlitestructure.Afterthermomechanicaltreatment,surfaceconsistsoftemperedmartensiteandcoreofferritepearlite.Thetemperedmartensitesurfacelayerisveryhardwhilethemicrostructureofthecoreisaveryfine-grainedpearlitewhichissoft.TheresultisastructureinTMTbarwithahighyieldstrengthcombinedwithhighductility.TMTbarsarealsoknownas'QuenchedandTemperedRebars',becauseofthequenchingandtemperingprocessesinvolvedinmakingtheTMTbars.IS1786:2008HighStrengthDeformedSteelBarsandWiresforConcreteReinforcementChemicalCompositionConstituentPercent,MaximumFe415Fe415DFe500Fe500DFe550Fe550DFe600Carbon,Max0.300.250.300.250.300.250.30Sulphur,Max0.0600.0450.0550.0400.0550.0400.040Phosphorus,Max0.0600.0450.0550.0400.0500.0400.040S+P,Max0.1100.0850.1050.0750.1000.0750.075MECHANICALPROPERTIESElementIS1786:2008Fe415Fe415DFe500Fe500DFe550Fe550DFe600YieldStrength,Min(N/mm2)415500550UltimatetensileStrength,Min(N/mm2)485545585Elongation,Min(A5)(%)14.5128NominalCross-SectionalAreaandMassSl.No.NominalSizemmCrossSectionalAreamm2MassperMetrickg(1)(2)(3)(4)1412.60.0992519.60.1543628.30.2224850.30.39551078.60.617612113.10.888716201.21.58820314.32.47925491.13.851028615.84.831132804.66.3112361018.37.9913401257.29.86ToleranceonNominalMassSl.No.NominalSizemmToleranceontheNominalMass,PercentBatchIndividualSample1IndividualSampleforcoilsOnly2(1)(2)(3)(4)(5)1Uptoandincluding10±7-8±82Over10uptoandincluding16±5-6±63±3-4±41)Forindividualsampleplustoleranceisnotspecified.Asinglesampletakenfromabatchasdefinedin3.1shallnotbeconsideredasindividualsample.2)Forcoilbatchtoleranceisnotspecified.PhysicalPropertiesMECHANICALPROPERTIESOFHIGHSTRENGTHDEFORMEDBARSANDWIRESSI.PropertyNo.Fe415Fe415DFe500Fe500DFe550Fe550DFe600123456789(I)0.2percentproofstress/yieldstress,MinN/mm2415.0415.0500.0500.0550.0550.0600.0(ii)Elongation,percent,Min,ongaugelength5.65A,WhereAisthecross-sectionalareaofthetestpiece14.518.012.016.010.014.510.0(iii)Tensilestrength,Min10percentmorethantheactual0.2percentproofstress/yieldstressbutnotlessthan485.0N/mm212percentmorethantheactual0.2percentproofstress/yieldstressbutnotlessthan500.0N/mm28percentmorethantheactual0.2percentproofstress/yieldstressbutnotlessthan545.0N/mm210percentmorethantheactual0.2percentproofstress/yieldstressbutnotlessthan565.0N/mm26percentmorethantheactual0.2percentproofstress/yieldstressbutnotlessthan585.0N/mm28percentmorethantheactual0.2percentproofstress/yieldstressbutnotlessthan600.0N/mm26percentmorethantheactual0.2percentproofstress/yieldstressbutnotlessthan660.0N/mm2(iv)Totalelongationatmaximumforce,percent,Minongaugelength5.65A,whereAisthecross-sectionalareaofthetestpiece-5-5-5-BENDPROPERTIESNOMINALSIZEmmMANDRALDIAMETERFORDIFFERENTGRADES(IS1786:2008)Fe415Fe415DFe500Fe500DFe550Fe550DFe600Uptoandincluding203d2d4d3d5d4d5dOver224d3d5d4d6d5d6ddisthenormalsizeinmmofthetestpiece.REBENDPROPERTIESNOMINALSIZEmmMANDRALDIAMETERFORDIFFERENTGRADES(IS1786:2008)Fe415and500Fe415Dand500DFe550and600Fe550DUptoandincluding105d4d7d6dOver107d6d8d7dWEIGHTTOLERANCESizeOfBar(mm2)Cross-SectionalArea(mm2)IS1786LowerStandardUpper850.30.3670.3950.4231078.60.5740.6170.6612113.10.8440.8880.93216201.21.5011.581.65920314.32.3962.472.54425491.13.7353.853.966