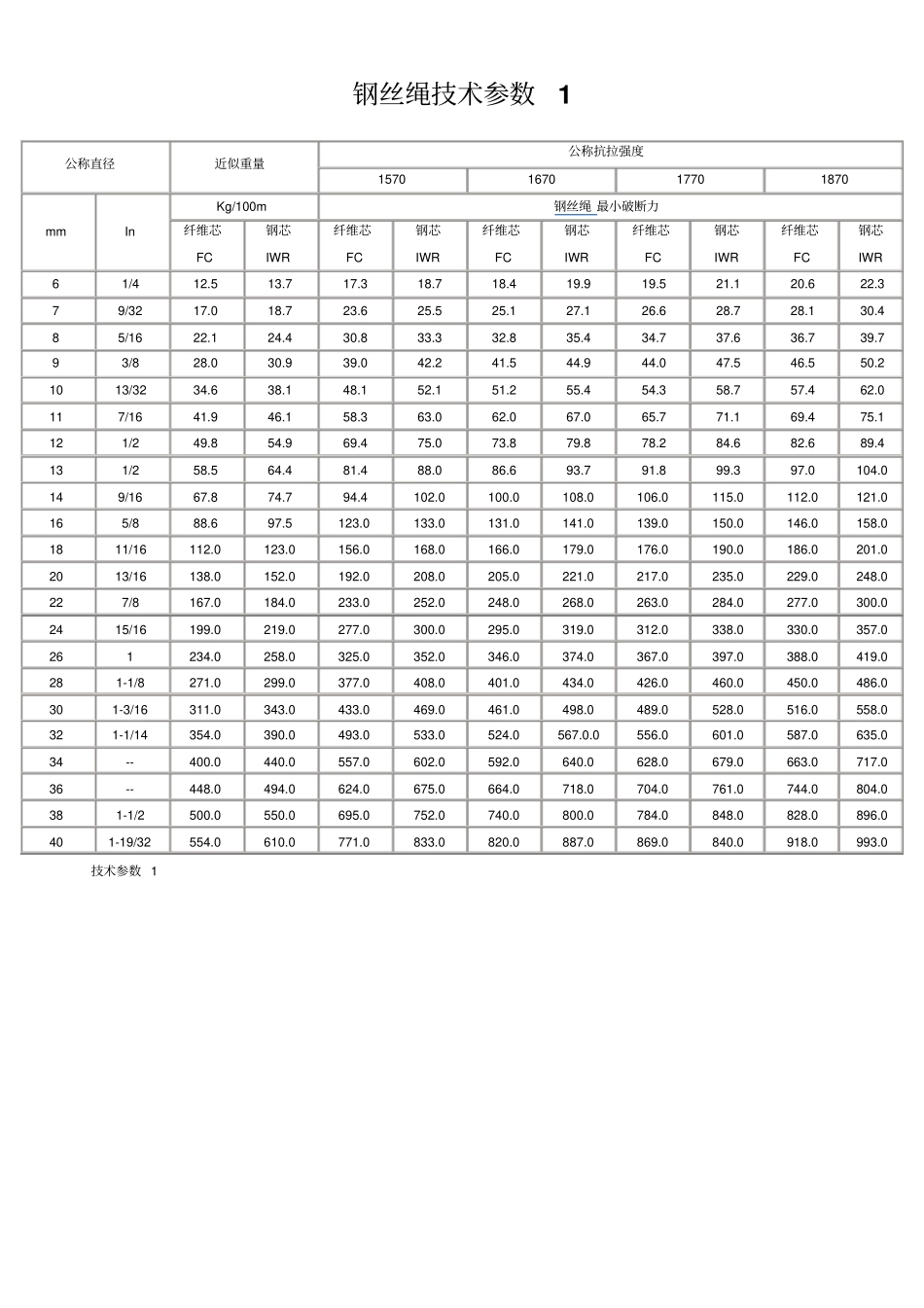

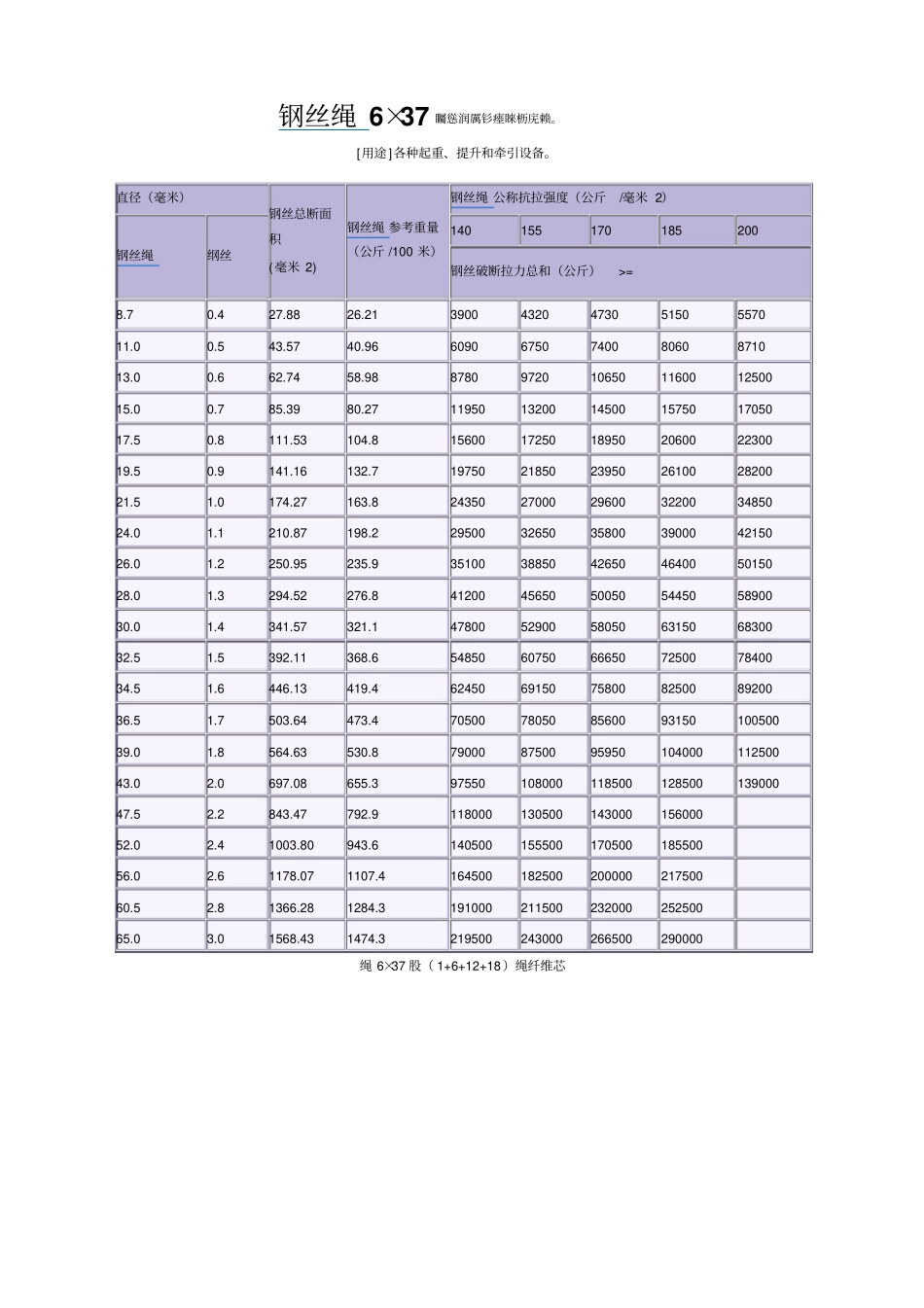

钢丝绳技术参数1技术参数1公称直径近似重量公称抗拉强度1570167017701870mmInKg/100m钢丝绳最小破断力纤维芯FC钢芯IWR纤维芯FC钢芯IWR纤维芯FC钢芯IWR纤维芯FC钢芯IWR纤维芯FC钢芯IWR61/412.513.717.318.718.419.919.521.120.622.379/3217.018.723.625.525.127.126.628.728.130.485/1622.124.430.833.332.835.434.737.636.739.793/828.030.939.042.241.544.944.047.546.550.21013/3234.638.148.152.151.255.454.358.757.462.0117/1641.946.158.363.062.067.065.771.169.475.1121/249.854.969.475.073.879.878.284.682.689.4131/258.564.481.488.086.693.791.899.397.0104.0149/1667.874.794.4102.0100.0108.0106.0115.0112.0121.0165/888.697.5123.0133.0131.0141.0139.0150.0146.0158.01811/16112.0123.0156.0168.0166.0179.0176.0190.0186.0201.02013/16138.0152.0192.0208.0205.0221.0217.0235.0229.0248.0227/8167.0184.0233.0252.0248.0268.0263.0284.0277.0300.02415/16199.0219.0277.0300.0295.0319.0312.0338.0330.0357.0261234.0258.0325.0352.0346.0374.0367.0397.0388.0419.0281-1/8271.0299.0377.0408.0401.0434.0426.0460.0450.0486.0301-3/16311.0343.0433.0469.0461.0498.0489.0528.0516.0558.0321-1/14354.0390.0493.0533.0524.0567.0.0556.0601.0587.0635.034--400.0440.0557.0602.0592.0640.0628.0679.0663.0717.036--448.0494.0624.0675.0664.0718.0704.0761.0744.0804.0381-1/2500.0550.0695.0752.0740.0800.0784.0848.0828.0896.0401-19/32554.0610.0771.0833.0820.0887.0869.0840.0918.0993.0钢丝绳6×37矚慫润厲钐瘗睞枥庑赖。[用途]各种起重、提升和牵引设备。绳6×37股(1+6+12+18)绳纤维芯直径(毫米)钢丝总断面积(毫米2)钢丝绳参考重量(公斤/100米)钢丝绳公称抗拉强度(公斤/毫米2)钢丝绳纲丝140155170185200钢丝破断拉力总和(公斤)>=8.70.427.8826.213900432047305150557011.00.543.5740.966090675074008060871013.00.662.7458.988780972010650116001250015.00.785.3980.27119501320014500157501705017.50.8111.53104.8156001725018950206002230019.50.9141.16132.7197502185023950261002820021.51.0174.27163.8243502700029600322003485024.01.1210.87198.2295003265035800390004215026.01.2250.95235.9351003885042650464005015028.01.3294.52276.8412004565050050544505890030.01.4341.57321.1478005290058050631506830032.51.5392.11368.6548506075066650725007840034.51.6446.13419.4624506915075800825008920036.51.7503.64473.47050078050856009315010050039.01.8564.63530.879000875009595010400011250043.02.0697.08655.39755010800011850012850013900047.52.2843.47792.911800013050014300015600052.02.41003.80943.614050015550017050018550056.02.61178.071107.416450018250020000021750060.52.81366.281284.319100021150023200025250065.03.01568.431474.3219500243000266500290000起重用具——钢丝绳(一)一、钢丝绳的用途及构造钢丝绳是起重机械的重要零件之一。它具有强度高、挠性好、自重轻、运行平稳、极少突然断裂等优点,因而广泛用于起重机的起升机构、变幅机构、索引机构,也可用于回转机构。它还用作捆绑物件的司索绳、桅杆起重机的张紧绳、缆索起重机和架重空道的承载索等。聞創沟燴鐺險爱氇谴净。钢丝绳要求很高的强度和韧性,常采用含碳量0.5%~0.8%的优质碳素钢制造。根据钢丝韧性(即允许弯折的次数),将钢丝分为三级:特级,用于载客电梯;Ⅰ级,用于一般起重机;Ⅱ级,用作司索绳、张紧绳等次要场合。为了防止腐蚀,也将钢丝表面镀锌。残骛楼諍锩瀨濟溆塹籟。钢丝绳由一定数量的钢丝和绳芯经过捻制而成。首先将钢丝捻成股,然后将若干股围绕着绳芯制成绳。钢丝是钢丝绳的基本强度单元。起重机用钢丝的强度一般为1470~1770MPa之间。绳芯是被绳股所缠绕的挠性芯棒,起到支撑和固定绳股的作用,并可以储存润滑油,增加钢丝绳的挠度。酽锕极額閉镇桧猪訣锥。根据适用的场合不同,绳芯分为以下几种:①金属芯——用软钢丝制成,可耐高温...