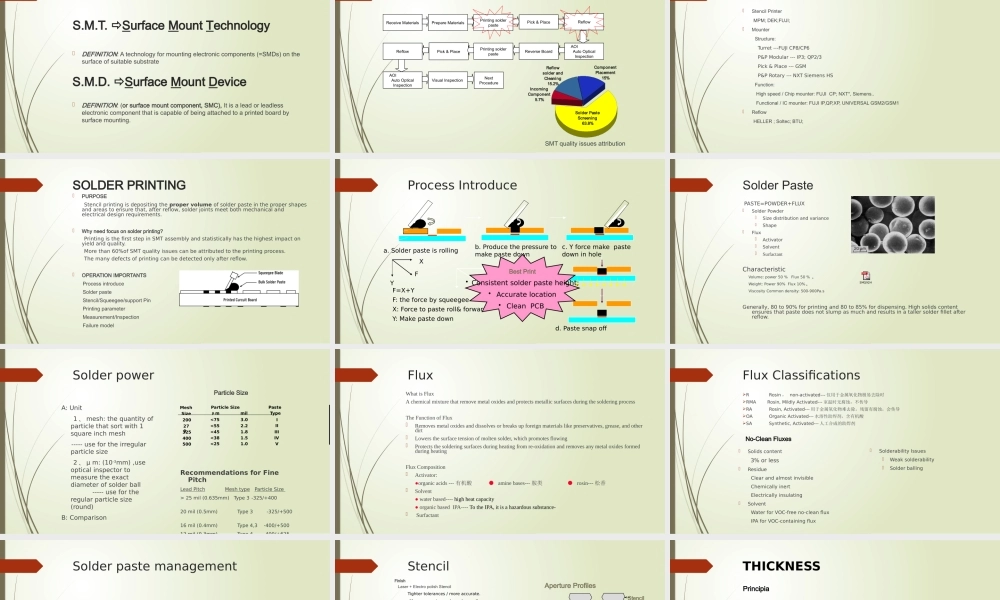

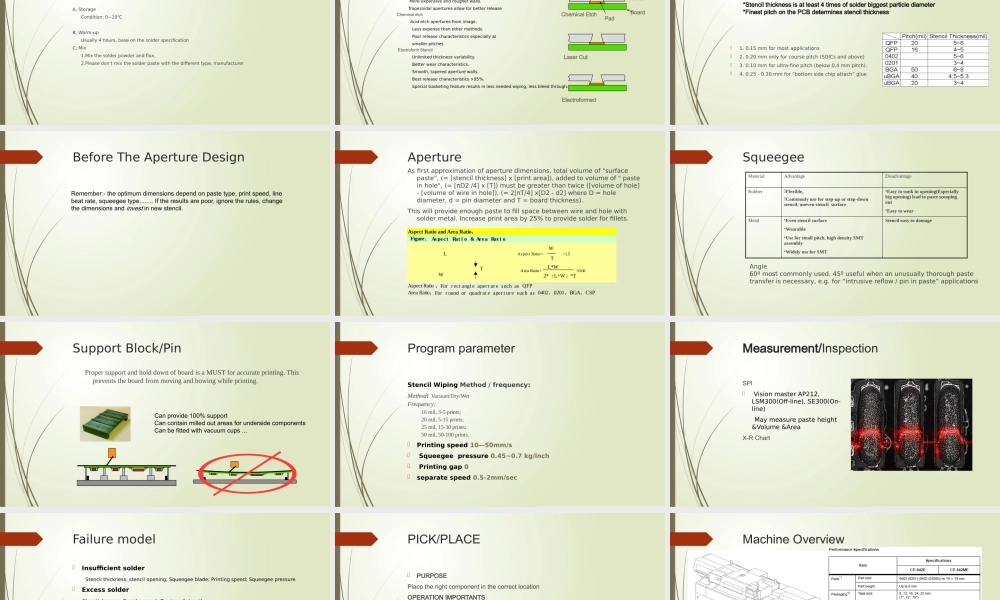

SMT PROCESS INTRODUCES.M.T. Surface Mount TechnologyDEFINITION: A technology for mounting electronic components (=SMDs) on the surface of suitable substrateS.M.D. Surface Mount DeviceDEFINITION: (or surface mount component, SMC), It is a lead or leadless electronic component that is capable of being attached to a printed board by surface mounting. WHAT IS SMT SMT FLOW Receive MaterialsPrepare MaterialsPrinting solder pastePick & PlaceReflowReflowPick & PlacePrinting solder pasteReverse BoardAOI Auto Optical InspectionAOI Auto Optical InspectionVisual Inspection Next ProcedureComponentPlacement15%Reflowsolder andCleaning15.2%Solder PasteScreening63.8%IncomingComponent5.7%SMT quality issues attributionSMT KEY EQUIPMENTStencil Printer MPM; DEK;FUJI;Mounter Structure: Turret ---FUJI CP8/CP6 P&P Modular --- IP3; QP2/3 Pick & Place --- GSM P&P Rotary --- NXT Siemens HS Function: High speed / Chip mounter: FUJI CP; NXT*, Siemens.. Functional / IC mounter: FUJI IP,QP,XP, UNIVERSAL GSM2/GSM1Reflow HELLER ; Soltec; BTU;SOLDER PRINTING PURPOSE Stencil printing is depositing the proper volume of solder paste in the proper shapes and areas to ensure that, after reflow, solder joints meet both mechanical and electrical design requirements.Why need focus on solder printing? Printing is the first step in SMT assembly and statistically has the highest impact on yield and quality. More than 60%of SMT quality issues can be attributed to the printing process. The many defects of printing can be detected only after reflow.OPERATION IMPORTANTS Process introduce Solder paste Stencil/Squeegee/support Pin Printing parameter Measurement/Inspection Failure modelProcess IntroduceXFYF=X+YF: the force by squeegeeX: Force to paste roll& forwardY: Make...