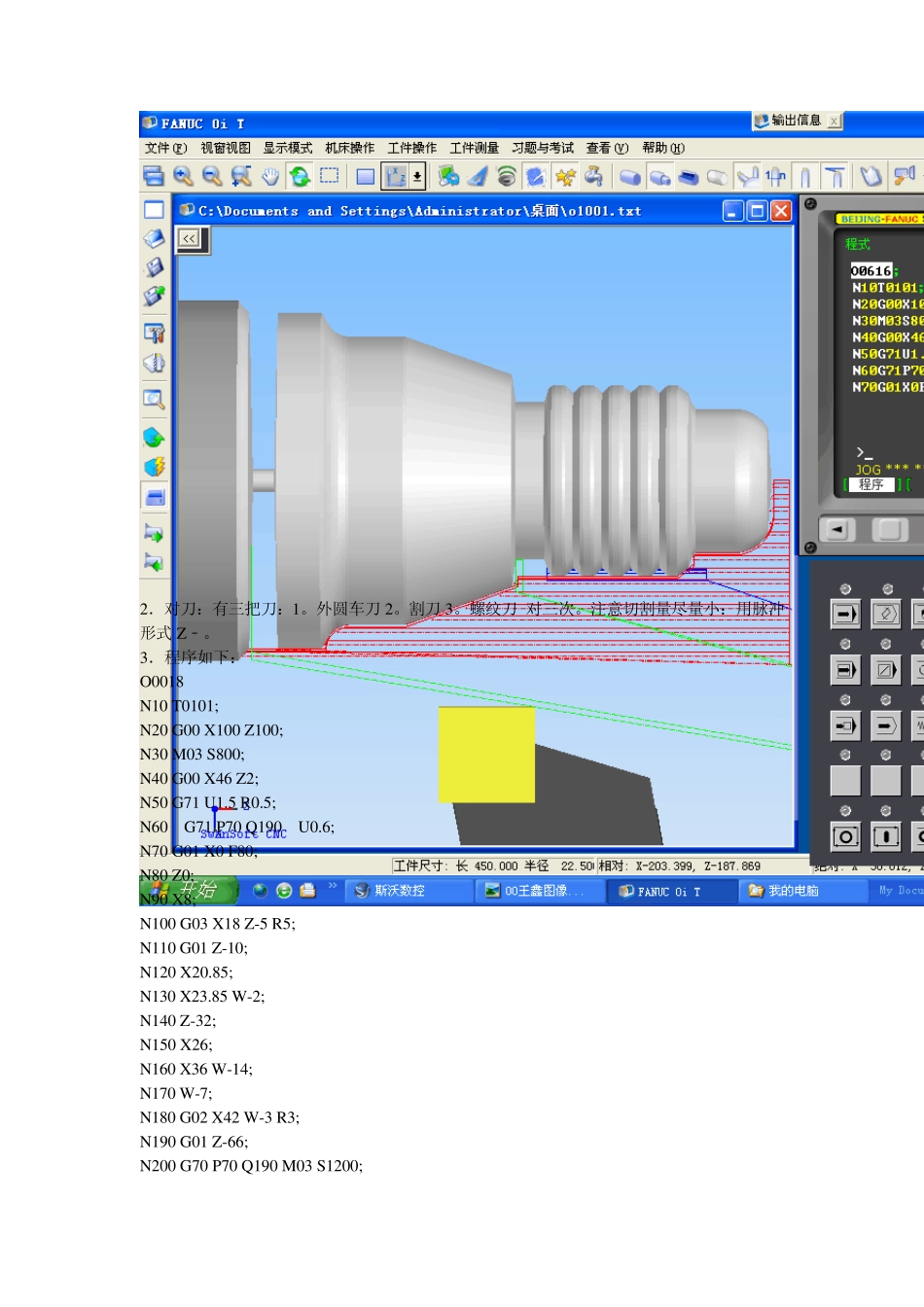

1 毛坯选着;1 0 0 x Ф 4 5 2.对刀:有三把刀:1。外圆车刀2。割刀3。螺纹刀 对三次。注意切割量尽量小:用脉冲形式 Z﹣。 3.程序如下: O0018 N10 T0101; N20 G00 X100 Z100; N30 M03 S800; N40 G00 X46 Z2; N50 G71 U1.5 R0.5; N60 G71 P70 Q190 U0.6; N70 G01 X0 F80; N80 Z0; N90 X8; N100 G03 X18 Z-5 R5; N110 G01 Z-10; N120 X20.85; N130 X23.85 W-2; N140 Z-32; N150 X26; N160 X36 W-14; N170 W-7; N180 G02 X42 W-3 R3; N190 G01 Z-66; N200 G70 P70 Q190 M03 S1200; N210 G00 X100 Z100; N220 T0202; N230 M03 S500; N240 G00 X28 Z-32; N250 G01 X20; N260 G00 X28; N270 W1; N280 G01 X20; N290 W-1; N300 G00 X28; N310 X100 Z100; N320 T0303; N330 M03 S400; N340 G00 X25 Z-9; N350 G92 X23.2 Z-29; F1.5; N360 X22.6; N370 X22.2; N380 X22.04; N390 G00 X100 Z100; N400 T0202; N410 G00 X43 Z-65; N420 G01 X3 F30 ; N430 G00 X45; N440 X100 Z100; N450 M30 斯沃数控-车床 编程与走刀-(2)hu ax ia 学院 机电工程----四把刀 O0633 N10 T0101; N20 G00 X100 Z100; N30 M03 S650; N40 G00 X46 Z2; %毛坯附近相差2mm N50 G71 U1.5 R0.5; %粗加工,u 每次切1.5mm,退刀量0.5 N60 G71 P70 Q160 U0.5 w0.1 F100; N70 G00 X0 ; N80 G01 Z0 F80; N90 X26; % 30-4D; N100 X30 Z-2; N110 Z-27; N120 X32; N130 X36 Z-35; N140 x-41; N150 X40 Z-65; N160 Z-76;%WHY? N170 G70 P70 Q160 M3 S800; %精加工 N180 G0 X100 Z100; N190 T0404 M3 S600; N200 G0 X38 Z-41; N210 G73 U3; %单边余粮 3mm N220 G73 P Q U0.3 W0 F60; N230 G01 X36 Z-41; N240 G02 U-6 W-9 R15; N250 U10 W15 R25; N260 G70 P230 Q250 M3 S800; % N270 T0202 M3 S450; N280 G0 X34 Z-27; N290 G01 X26 F30; N300 G0 X34; N310 W3; N320 X26 N330 W-3; N340 GO X34; N350 X32 Z-21; N360 G1 X26 Z-24; N370 G0 X34; N380 X100 Z100; N390 T0303; N400 G0 X32 Z3; N410 G92 X29.2 Z-22 F1.5; N420 X28.6; N430 X28.2; N4...