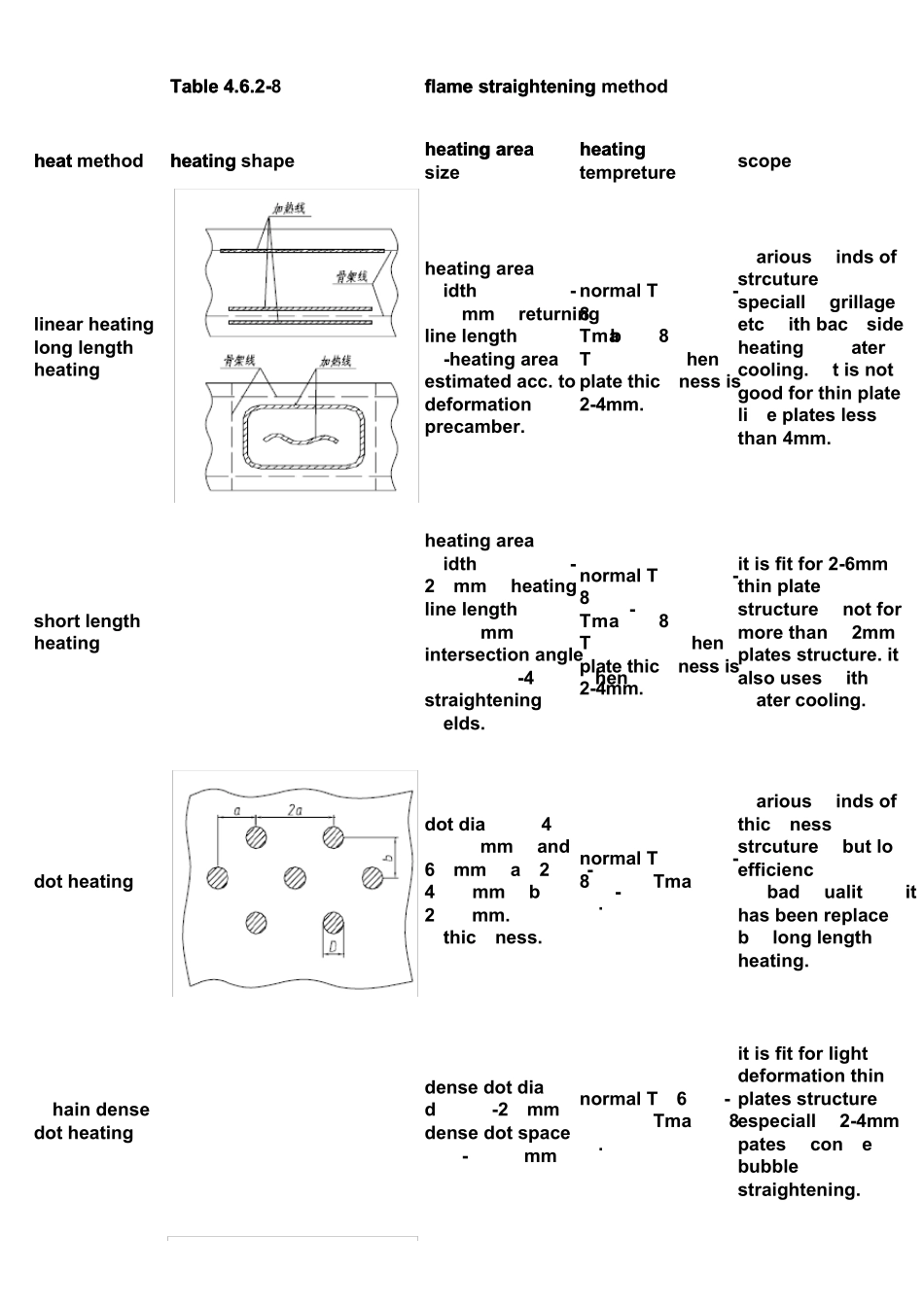

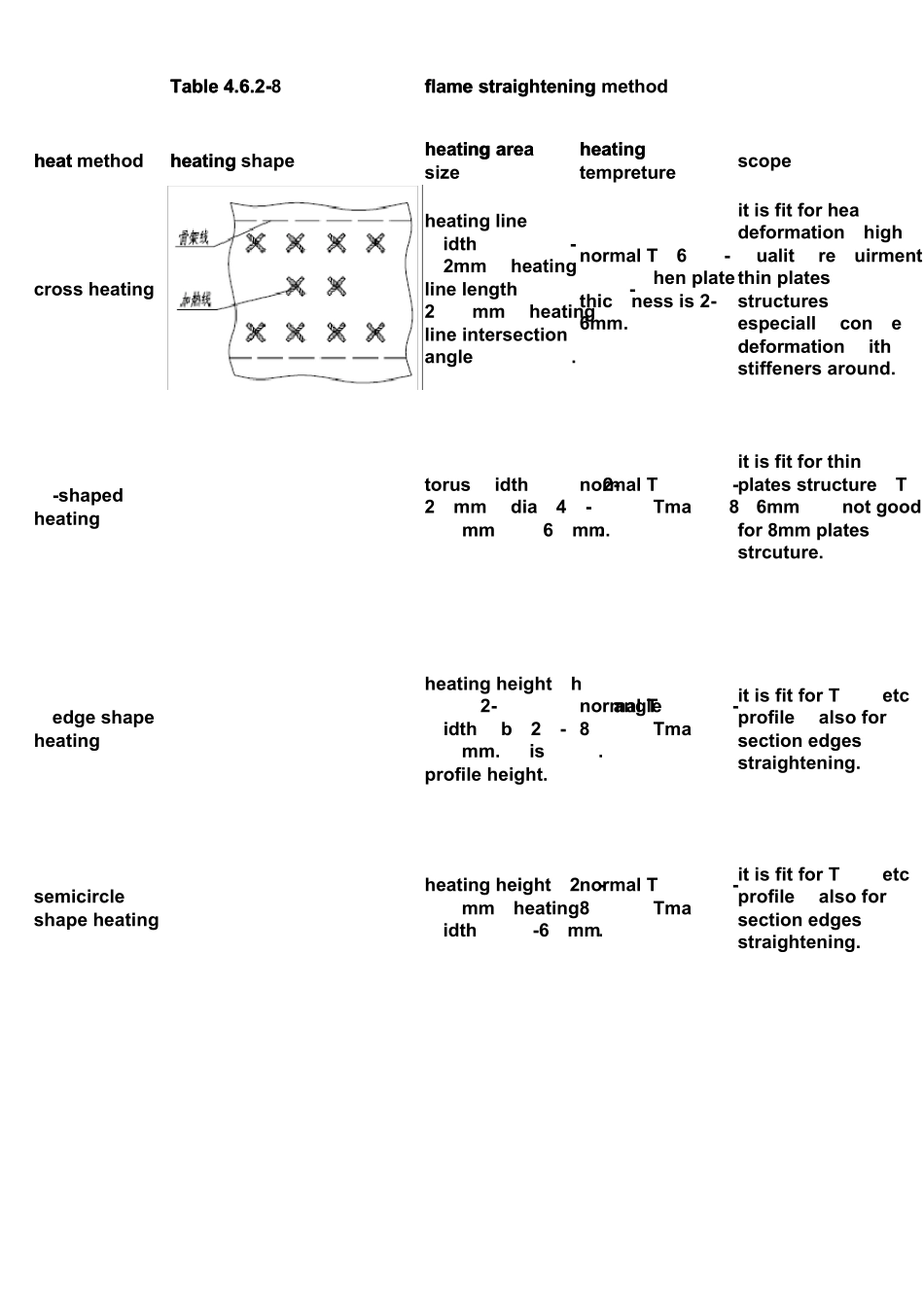

Flame straightening procedu re(general)Itdependsthe correctmethodofspotheatingdeformationThefactsof flamestraighteningresu ltisas belowinformation:1)thepositionofflamestraightening;2)Theshapeofflamestraightening;3)Theheat inpu tofflamestraightening.1.theheatingshapeofflamestraighteningA,spotheatingB,linearheatingC,triangleor halfcircleheatingD,radiatedheatingor forcedcooling2.flamestraighteningmethodand parametersA,flamestraighteningmethodpleasesee table4.6.2-8B,linearheatingmethodparameterspleasesee table4.6.2-9C,distancebetweenflametoneand stru ctu resu rfacepleasesee table4.6.2-10D,heatingdotsizedependson platesthickness,normallyΦ=4δ,pleasesee table4.6.2-113.Notice1)firstofall,platesmaterialshou ldbenoticedbeforestraightening.Smallchangedofmaterialproperty afterflamestraighteningifthe materialweldingpropertyis good.Eg.:carbonsteelstru ctu reand 16Mnsteel stru ctu rehaveverygood weldingproperty.Thesenot onlycan bestraighten byflaming,bu tcan bewater cooling ifthe thicknessis not big.Thelowesttemperatu reofflamingcan be360℃,highesttemperatu re900℃ shou ldbeu nderthe control.Watercoolingmethodneedsto waitu ntilthesteelcolorisnotred beforeapplyingwater.2)normallypeopleu seneu tralflame;oxydizingflamecanbeu sedwhenlowthickheating.3)confirmdeformationsitu ation,heatingpositionand straightenstepsbeforestartingflaming.4)considersu nlighteffectdu ringsu mmerhotdays5)malletshou ldbeu sedwhenhittingneededdu ringflamestraightening.6)considerthecomingprocessafterflamestraightening7)heating dots shou ldnot beoverlappedwhenflamestraighteningmanytimes.Normallycarbonsteelrepeatflamestraighteninglessthan5times,lowalloyedsteellessthan3times.8)the steelsu rfaceshou ldbeplaneafterflamestraightening,no irregu larityor remaininglocaldeformationand hammeringmarks.TableTable 4.6.24.6.2--8flameflame straighteningstraightening methodheatheat methodheatingheating shapeheatingheating areaarea sizeheatingh...