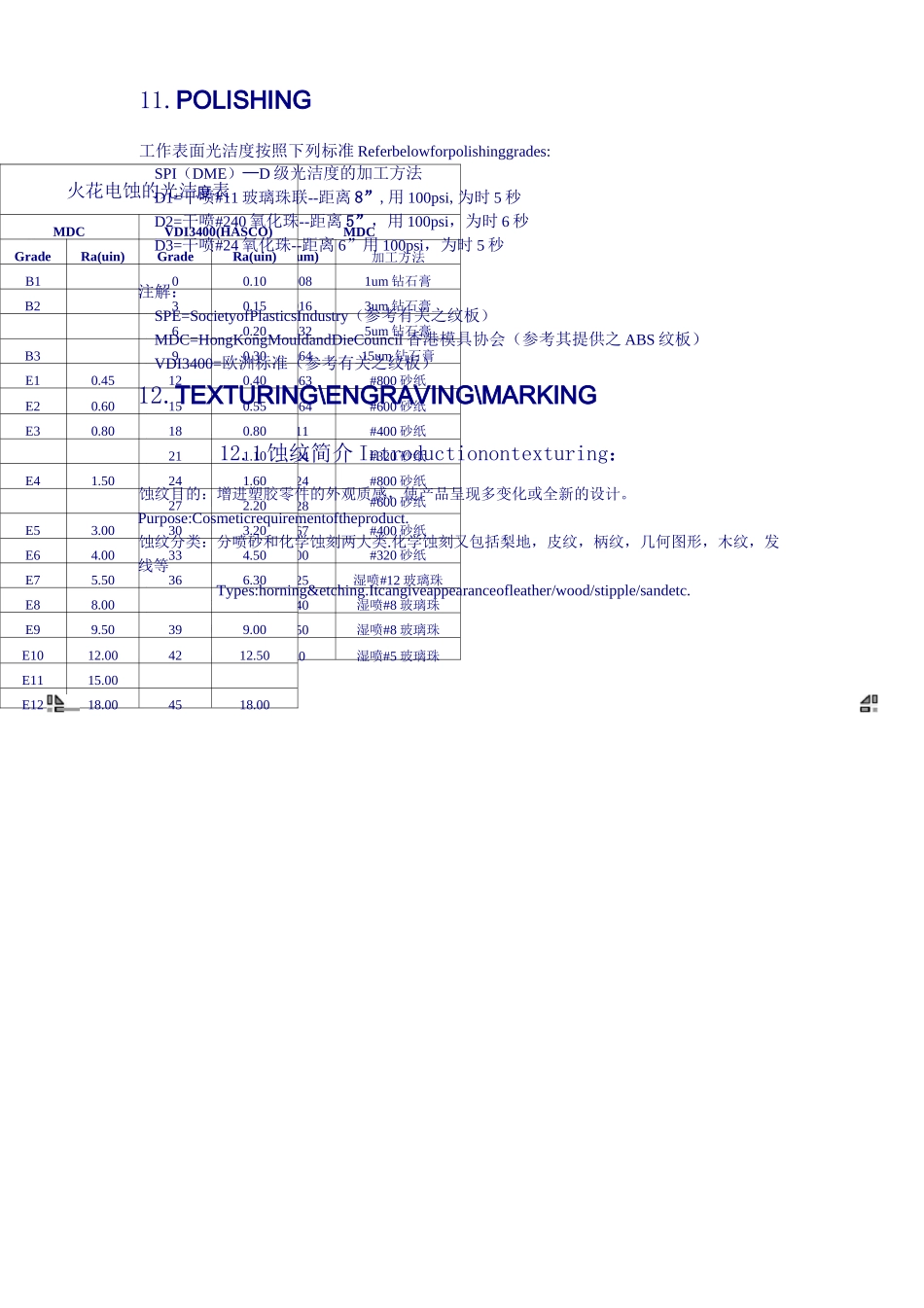

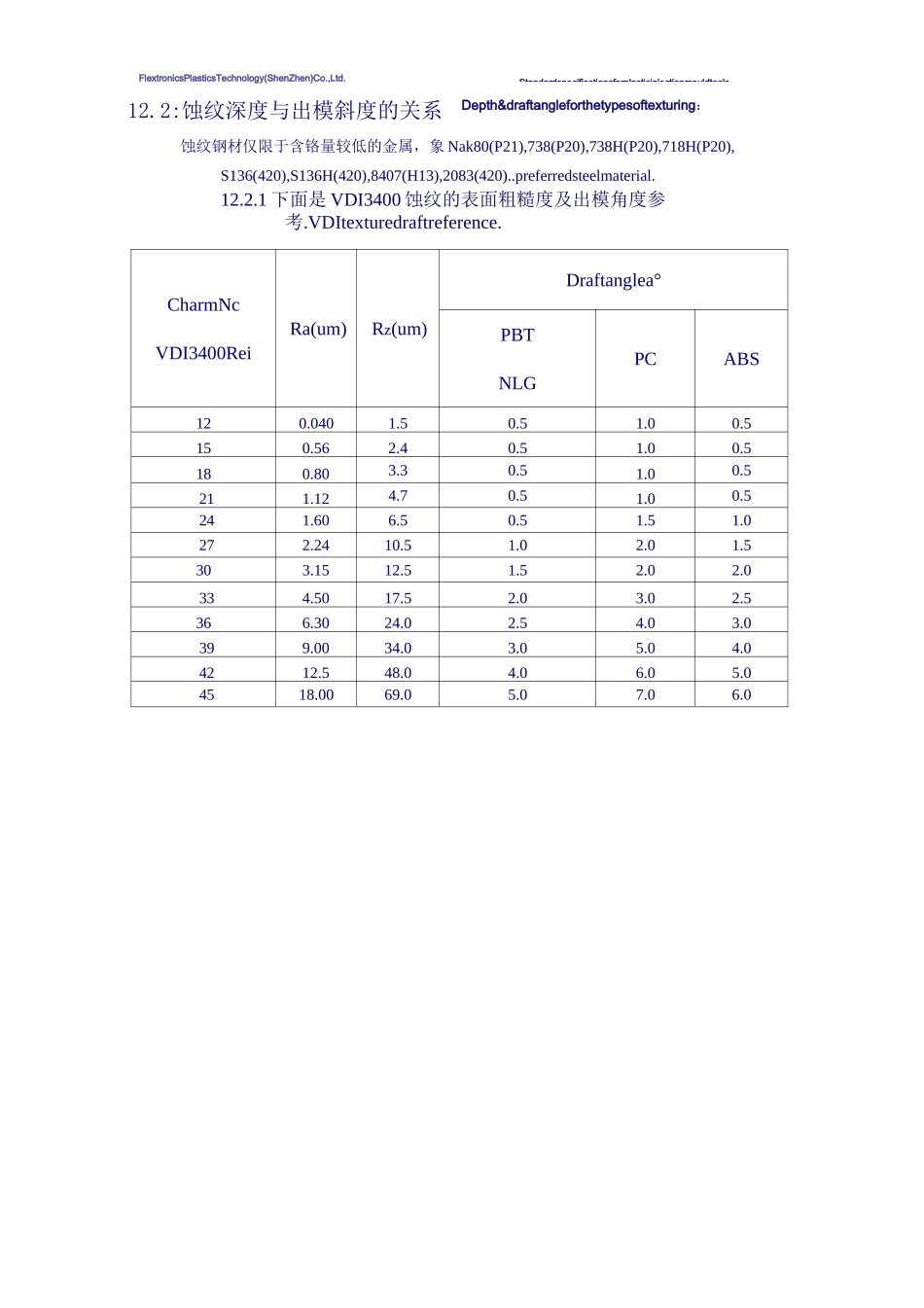

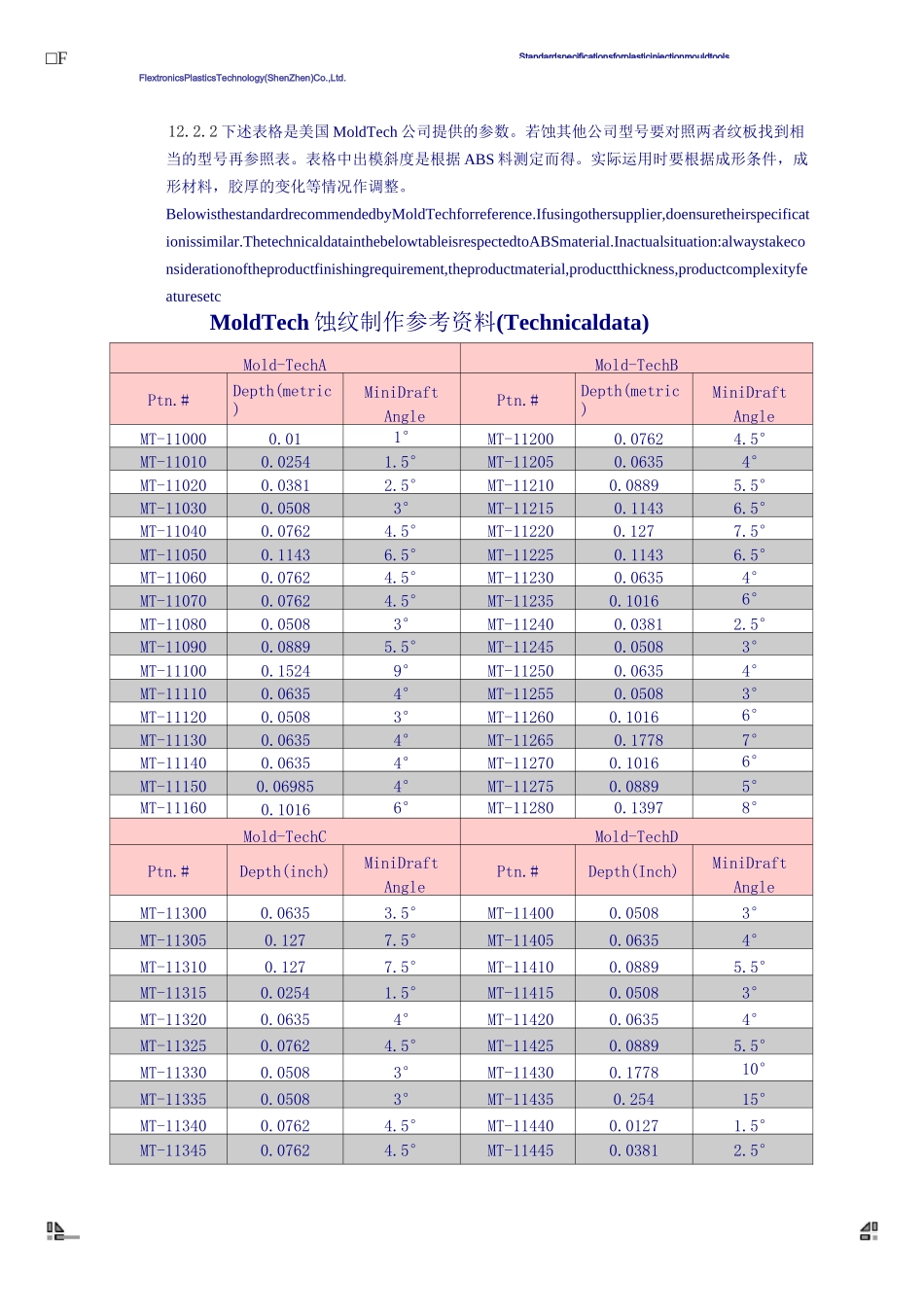

抛光光洁度表标准SPI(DME)MDCGradeRa(uin)加工方法Ra(um)加工方法A00.0081um 钻石膏A10-1#3 钻石膏0.0163um 钻石膏A21-2#6 钻石膏0.0325um 钻石膏A32-3#15 钻石膏0.06415um 钻石膏B00.063#800 砂纸B12-3#600 砂纸0.064#600 砂纸B23-5#400 砂纸0.11#400 砂纸B39-10#320 砂纸0.24#320 砂纸C00.24#800 砂纸C110-12#800 油石0.28#600 砂纸C225-28#400 油石0.67#400 砂纸C338-42#320 油石1.00#320 砂纸D00.25湿喷#12 玻璃珠D110-12干喷#11 玻璃珠0.40湿喷#8 玻璃珠D226-32干喷#24 氧化珠0.50湿喷#8 玻璃珠D3190-230干喷#24 氧化珠2.0湿喷#5 玻璃珠火花电蚀的光洁度表MDCVDI3400(HASCO)GradeRa(uin)GradeRa(uin)B100.10B230.1560.20B390.30E10.45120.40E20.60150.55E30.80180.80211.10E41.50241.60272.20E53.00303.20E64.00334.50E75.50366.30E88.00E99.50399.00E1012.004212.50E1115.00E1218.004518.0011.POLISHING工作表面光洁度按照下列标准 Referbelowforpolishinggrades:SPI(DME)—D 级光洁度的加工方法D1=干喷#11 玻璃珠联--距离 8”,用 100psi,为时 5 秒D2=干喷#240 氧化珠--距离 5”,用 100psi,为时 6 秒D3=干喷#24 氧化珠--距离 6”用 100psi,为时 5 秒注解:SPE=SocietyofPlasticsIndustry(参考有关之纹板)MDC=HongKongMouldandDieCouncil 香港模具协会(参考其提供之 ABS 纹板)VDI3400=欧洲标准(参考有关之纹板)12.TEXTURING\ENGRAVING\MARKING12.1 蚀纹简介 Introductionontexturing:蚀纹目的:增进塑胶零件的外观质感,使产品呈现多变化或全新的设计。Purpose:Cosmeticrequirementoftheproduct.蚀纹分类:分喷砂和化学蚀刻两大类.化学蚀刻又包括梨地,皮纹,柄纹,几何图形,木纹,发线等Types:horning&etching.Itcangiveappearanceofleather/wood/stipple/sandetc.StandardspecificationsforplasticinjectionmouldtoolsFlextronicsPlasticsTechnology(ShenZhen)Co.,Ltd.12.2:蚀纹深度与出模斜度的关系Depth&draftangleforthetypesoftexturing:蚀纹钢材仅限于含铬量较低的金属,象 Nak80(P21),738(P20),738H(P20),718H(P20),S136(420),S136H(420),8407(H13),2083(420)..preferredsteelmaterial.12.2.1 下面是 VDI3400 蚀纹的表面粗糙度及出模角度参考.VDItexturedraftreference.CharmNcVDI3400ReiRa(um)Rz(um)Draftanglea°PBTNLGPCABS120.0401.50.51.00.5150.562.40.51...