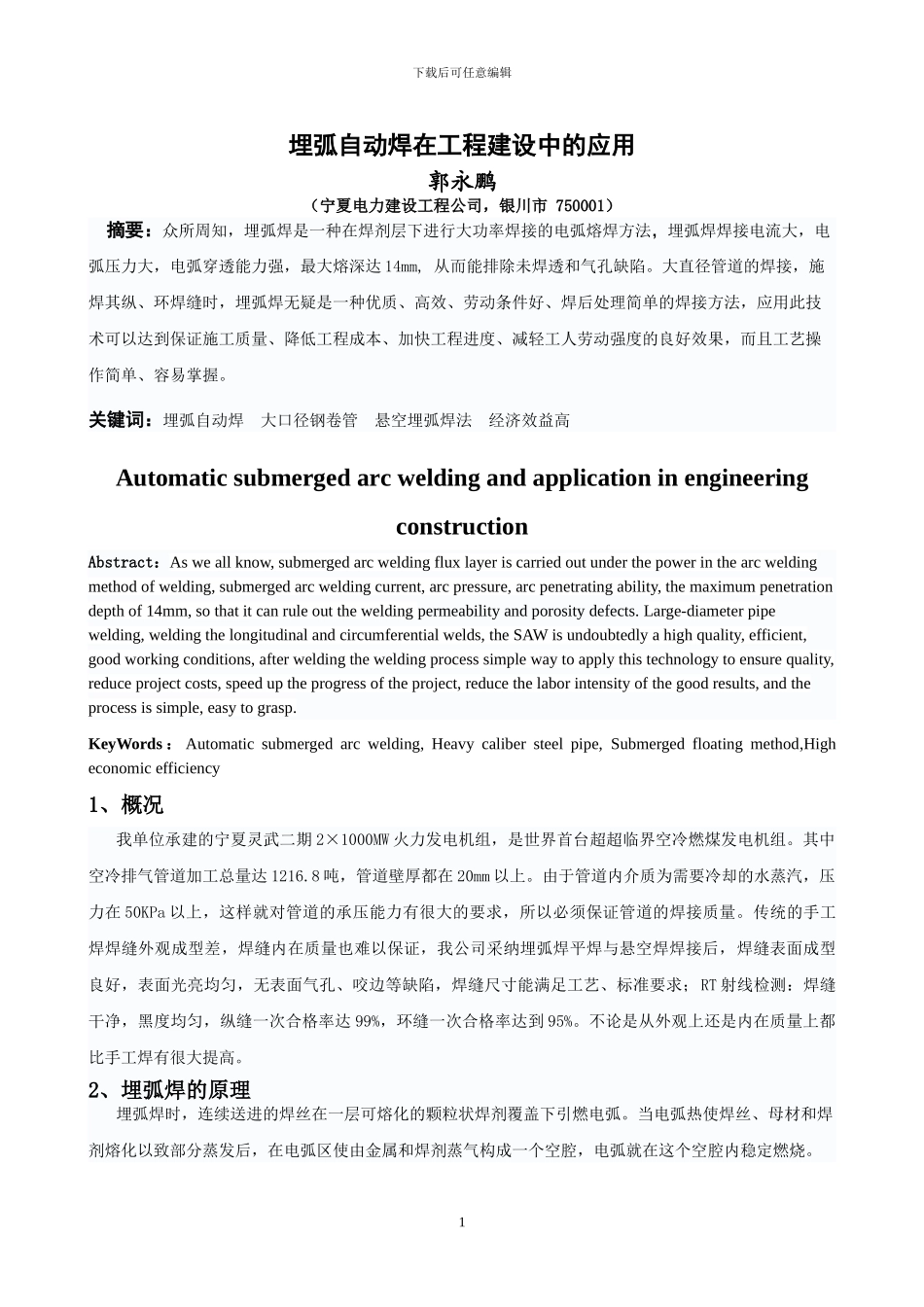

下载后可任意编辑埋弧自动焊在工程建设中的应用郭永鹏(宁夏电力建设工程公司,银川市 750001)摘要:众所周知,埋弧焊是一种在焊剂层下进行大功率焊接的电弧熔焊方法,埋弧焊焊接电流大,电弧压力大,电弧穿透能力强,最大熔深达 14mm, 从而能排除未焊透和气孔缺陷。大直径管道的焊接,施焊其纵、环焊缝时,埋弧焊无疑是一种优质、高效、劳动条件好、焊后处理简单的焊接方法,应用此技术可以达到保证施工质量、降低工程成本、加快工程进度、减轻工人劳动强度的良好效果,而且工艺操作简单、容易掌握。关键词:埋弧自动焊 大口径钢卷管 悬空埋弧焊法 经济效益高Automatic submerged arc welding and application in engineering constructionAbstract:As we all know, submerged arc welding flux layer is carried out under the power in the arc welding method of welding, submerged arc welding current, arc pressure, arc penetrating ability, the maximum penetration depth of 14mm, so that it can rule out the welding permeability and porosity defects. Large-diameter pipe welding, welding the longitudinal and circumferential welds, the SAW is undoubtedly a high quality, efficient, good working conditions, after welding the welding process simple way to apply this technology to ensure quality, reduce project costs, speed up the progress of the project, reduce the labor intensity of the good results, and the process is simple, easy to grasp.KeyWords : Automatic submerged arc welding, Heavy caliber steel pipe, Submerged floating method,High economic efficiency1、概况我单位承建的宁夏灵武二期 2×1000MW 火力发电机组,是世界首台超超临界空冷燃煤发电机组。其中空冷排气管道加工总量达 1216.8 吨,管道壁厚都在 20mm 以上。由于管道内介质为需要冷却的水蒸汽,压力在 50KPa 以上,这样就对管道的承压能力有很大的要求,所以必须保证管道的焊接质量。传统的手工焊焊缝外观成型差,焊缝内在质量也难以保证,我公司采纳埋弧焊平焊与悬空焊焊接后,焊缝表面成型良好,表面光亮均匀,无表面气孔、咬边等缺陷,焊缝尺寸能满足工艺...