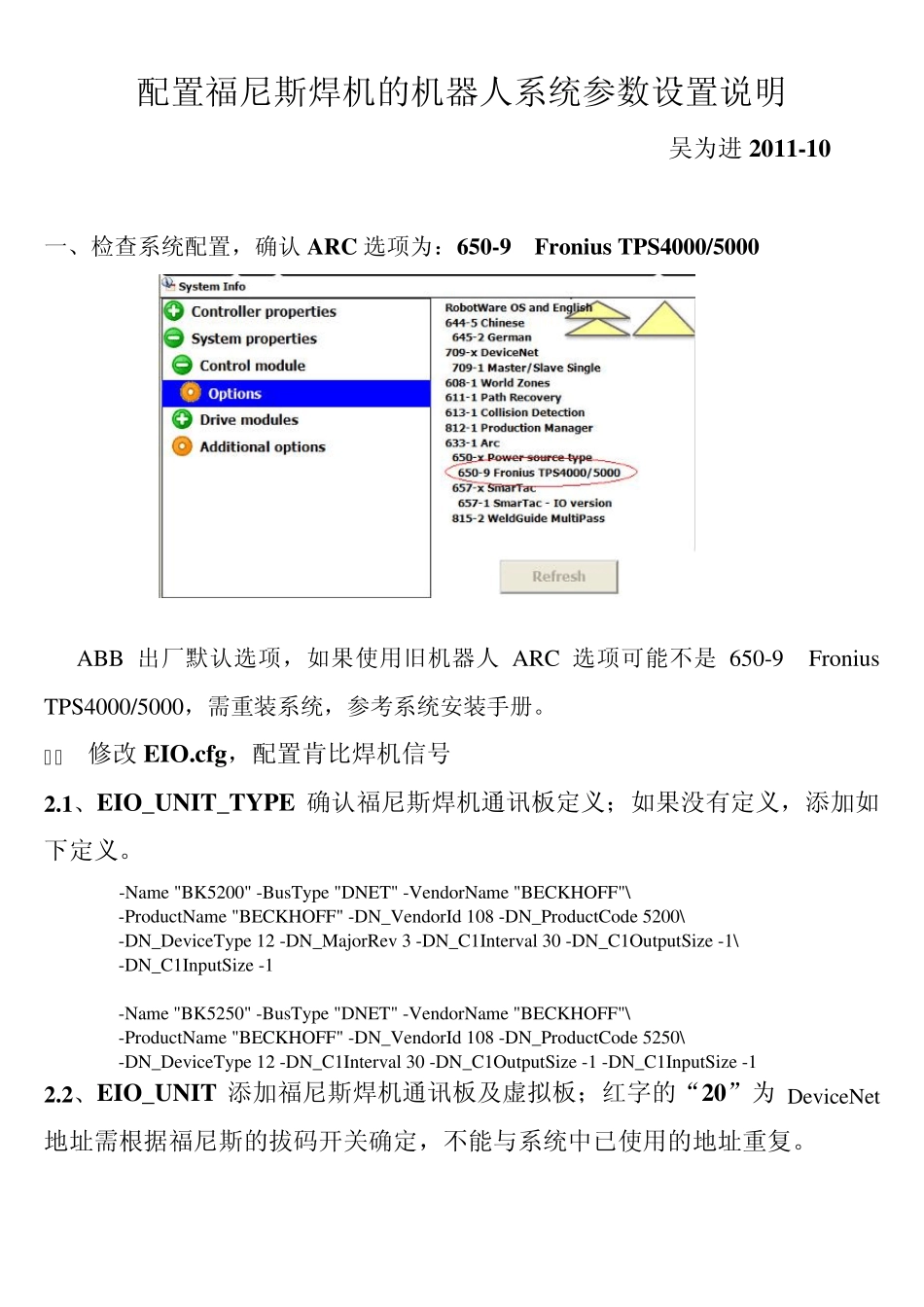

配置福尼斯焊机的机器人系统参数设置说明 吴为进2011-10 一、检查系统配置,确认ARC 选项为:650-9 Froniu s TPS4000/5000 ABB 出厂默认选项,如果使用旧机器人ARC 选项可能不是650-9 Fronius TPS4000/5000,需重装系统,参考系统安装手册。 二、修改EIO.cfg,配置肯比焊机信号 2.1、EIO_UNIT_TYPE 确认福尼斯焊机通讯板定义;如果没有定义,添加如下定义。 -Name "BK5200" -BusType "DNET" -VendorName "BECKHOFF"\ -ProductName "BECKHOFF" -DN_VendorId 108 -DN_ProductCode 5200\ -DN_DeviceType 12 -DN_MajorRev 3 -DN_C1Interval 30 -DN_C1OutputSize -1\ -DN_C1InputSize -1 -Name "BK5250" -BusType "DNET" -VendorName "BECKHOFF"\ -ProductName "BECKHOFF" -DN_VendorId 108 -DN_ProductCode 5250\ -DN_DeviceType 12 -DN_C1Interval 30 -DN_C1OutputSize -1 -DN_C1InputSize -1 2.2、EIO_UNIT 添加福尼斯焊机通讯板及虚拟板;红字的“20”为DeviceNet地址需根据福尼斯的拔码开关确定,不能与系统中已使用的地址重复。 -Name "ioFronius1" -UnitType "BK5250" -Bus "DeviceNet1" -DN_Address 20 -Name "ioFroniusSim1" -UnitType "Virtual" -Bus "Virtual1"\ -UnitLabel "RWArc Simulated welder" 2.3、EIO_SIGNAL 添加如下信号,所有信号不能修改; -Name "doFr1ArcOn" -SignalType "DO" -Unit "ioFronius1" -UnitMap "0" -Name "doFr1RobotReady" -SignalType "DO" -Unit "ioFronius1" -UnitMap "1" -Name "doFr1GasTest" -SignalType "DO" -Unit "ioFronius1" -UnitMap "8" -Name "doFr1FeedForward" -SignalType "DO" -Unit "ioFronius1" -UnitMap "9" -Name "doFr1FeedRetract" -SignalType "DO" -Unit "ioFronius1" -UnitMap "10" -Name "doFr1ErrorReset" -SignalType "DO" -Unit "ioFronius1" -UnitMap "11" -Name "doFr1TouchSense" -SignalType "DO" -Unit "ioFronius1" -UnitMap "12" -Name "doFr1TrchBlowOut" -SignalType "DO" -Unit "ioFronius1" -UnitMap "13" -Name "doFr1WeldingSim" -SignalType "DO" -Unit "ioFronius1" -UnitMap "31" -Name "diFr1ArcStable" -SignalType "DI" -Unit "ioFronius1" -UnitMap "0"\ -FiltPas 50 -Name "diFr1Pr...