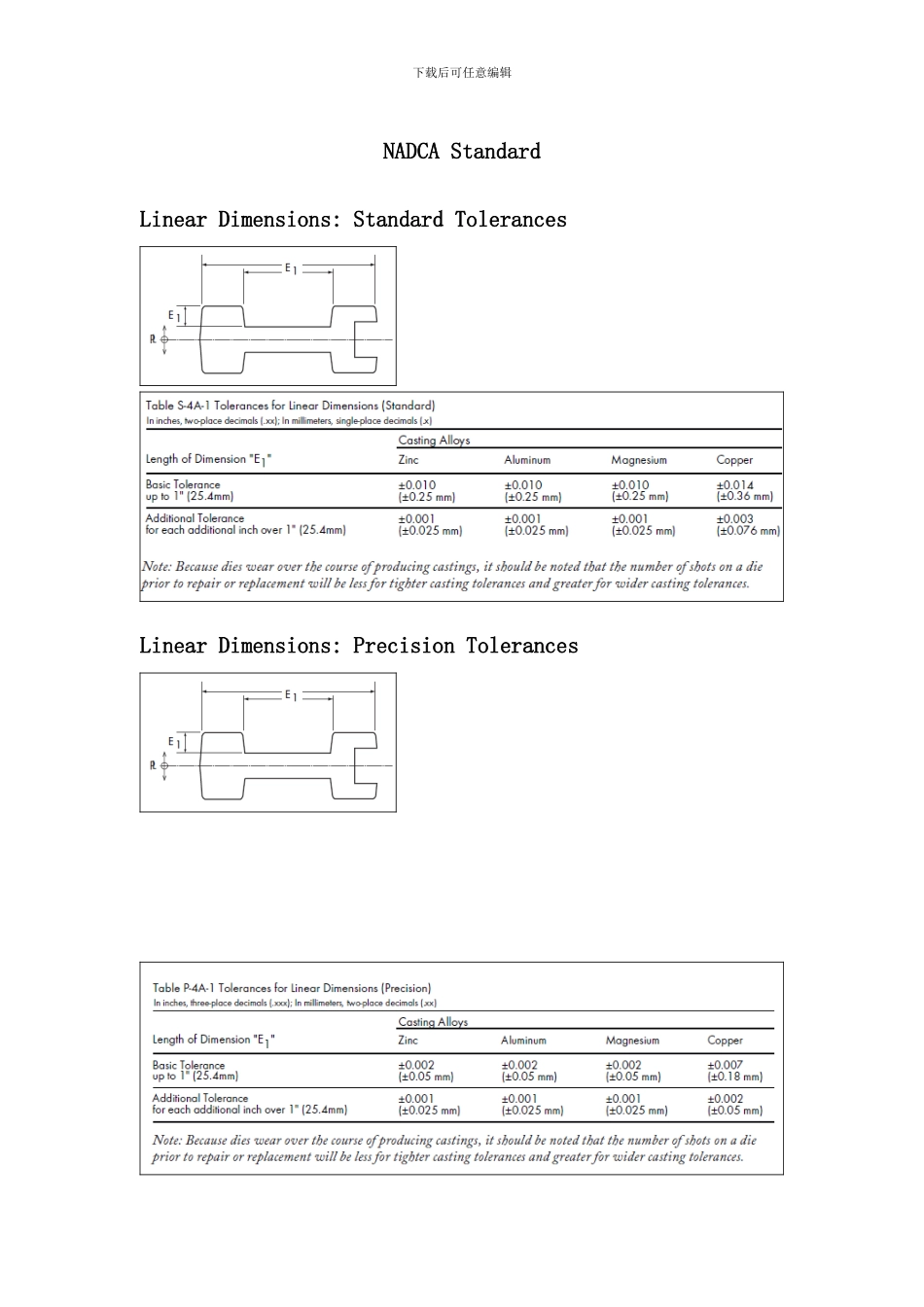

下载后可任意编辑NADCA StandardLinear Dimensions: Standard TolerancesLinear Dimensions: Precision Tolerances 下载后可任意编辑Parting Line: Standard TolerancesParting Line Tolerance is the maximum amount of die separation allowed for the end product to meet specified requirements of form, fit and function. This is not to be confused with Parting Line Shift Tolerance which is the maximum amount die halves shift from side to side in relation to one another.Parting Line Tolerance is a function of the surface area of the die from which material can flow from one die half to the other. This is also known as Projected Area.Projected Area is always a plus tolerance since a completely closed die has 0 separation. Excess material and pressure will force the die to open along the parting line plane creating an oversize condition. The excess material will cause the part to be thicker than the ideal specification and that is why Projected Area only has plus tolerance. It is important to understand that Table S-4A-2 (Projected Area Tolerance) does not provide Parting Line Tolerance by itself. Part thickness or depth must be factored in to give a true idea of Parting Line Tolerance. Parting Line Tolerance is a function of part thickness perpendicular to the Projected Area plus the Projected Area Tolerance.Example: An aluminum die casting has 75 in2 (483.9 cm2) 下载后可任意编辑of Projected Area on the parting die plane. From table S-4A-2, Projected Area Tolerance is +0.012. This is combined with the total part thickness tolerance from table S-4A-1 to obtain the Parting Line Tolerance.The total part thickness including both die halves is 5.00 in. (127 mm) which is measured perpendicular to the parting die plane (dim...