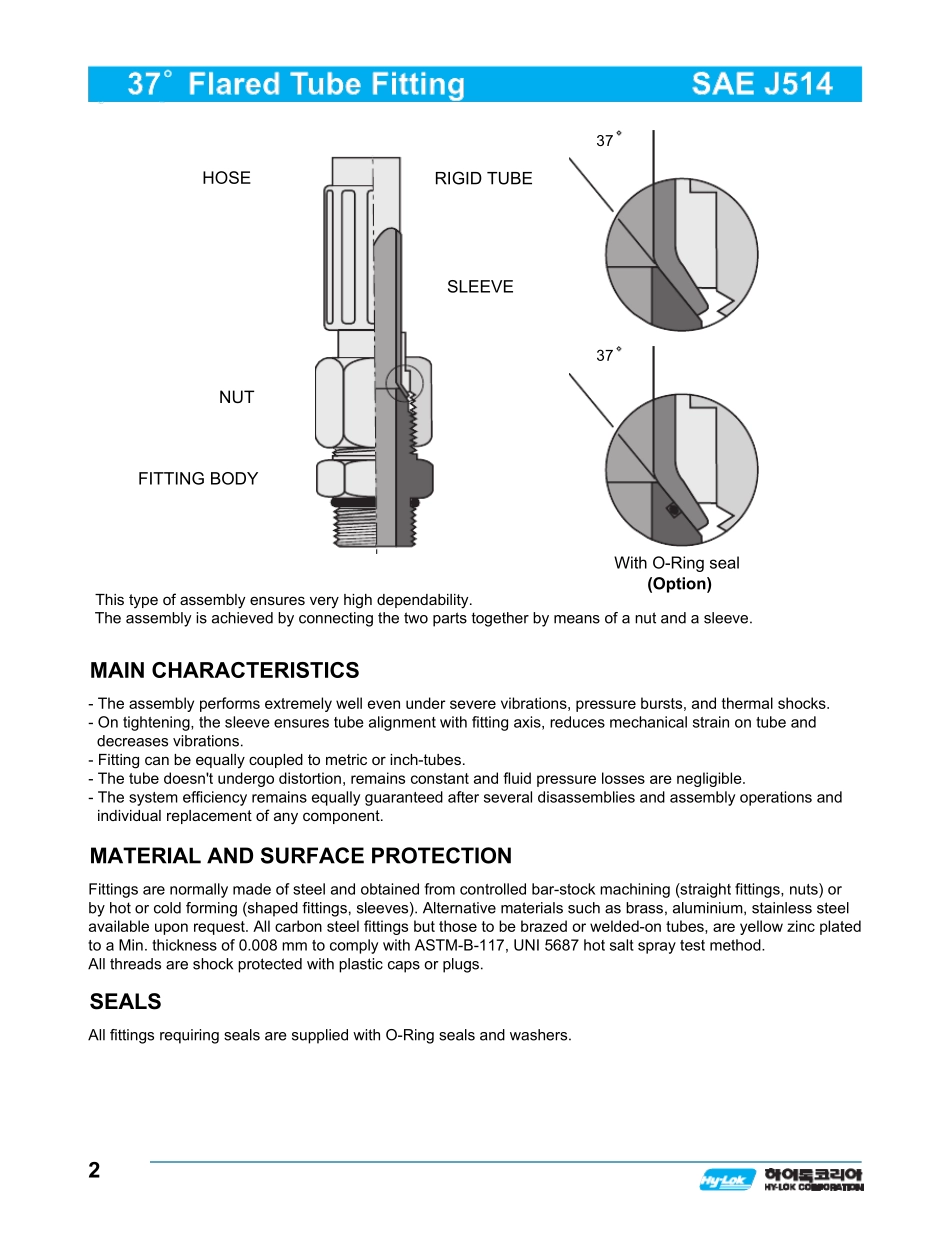

Tube Fittings w ith O-Ringfor Fractional and MetricCatalog No. H - 240FFMar. 200237 Flared SAE - J514The AmericanSociety ofMechanicalEngineersAmericanPetroleumInstituteGermanischerLioydDETNORSKEVERITASAmericanBureauShippingNIPPONKAIJIKYOKAIKOREA ELECTRICPOWER INDUSTRYCODEAlberta BoilersSafety Association3737HOSERIGID TUBEWith O-Ring seal(Option)SLEEVENUTFITTING BODYThis type of assembly ensures very high dependability. The assembly is achieved by connecting the two parts together by means of a nut and a sleeve.- The assembly performs extremely well even under severe vibrations, pressure bursts, and thermal shocks.- On tightening, the sleeve ensures tube alignment with fitting axis, reduces mechanical strain on tube and decreases vibrations.- Fitting can be equally coupled to metric or inch-tubes.- The tube doesn't undergo distortion, remains constant and fluid pressure losses are negligible.- The system efficiency remains equally guaranteed after several disassemblies and assembly operations and individual replacement of any component.Fittings are normally made of steel and obtained from controlled bar-stock machining (straight fittings, nuts) orby hot or cold forming (shaped fittings, sleeves). Alternative materials such as brass, aluminium, stainless steelavailable upon request. All carbon steel fittings but those to be brazed or welded-on tubes, are yellow zinc platedto a Min. thickness of 0.008 mm to comply with ASTM-B-117, UNI 5687 hot salt spray test method.All threads are shock protected with plastic caps or plugs.All fittings requiring seals are supplied with O-Ring seals and washers.MAIN CHARACTERISTICSMATERIAL AND SURFACE PROTECTIONSEALS26765757367657573D37.536.537.536.5RTRO.5D1TS1RSRO.5Tube flaring is carried out in two differente ways ...