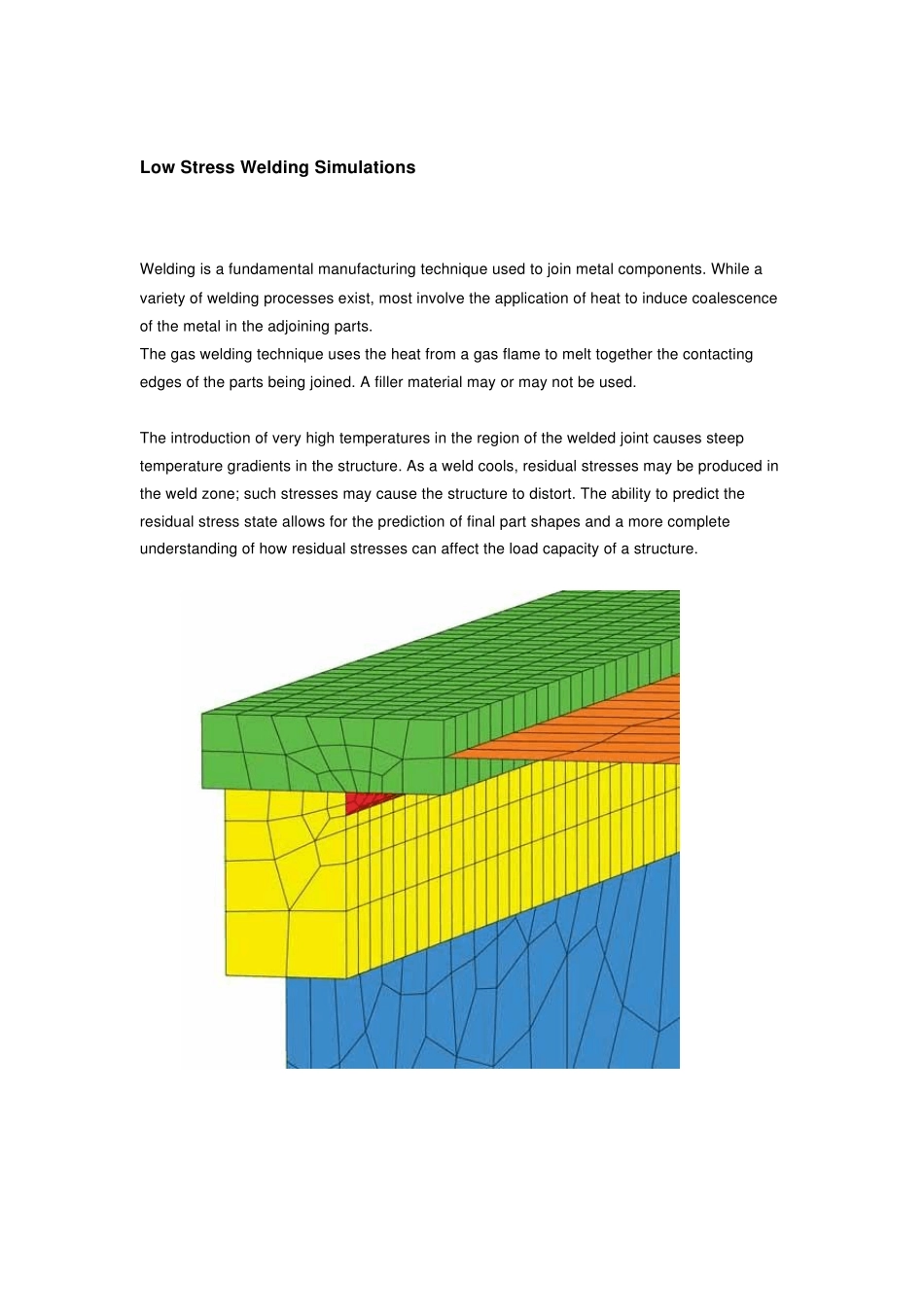

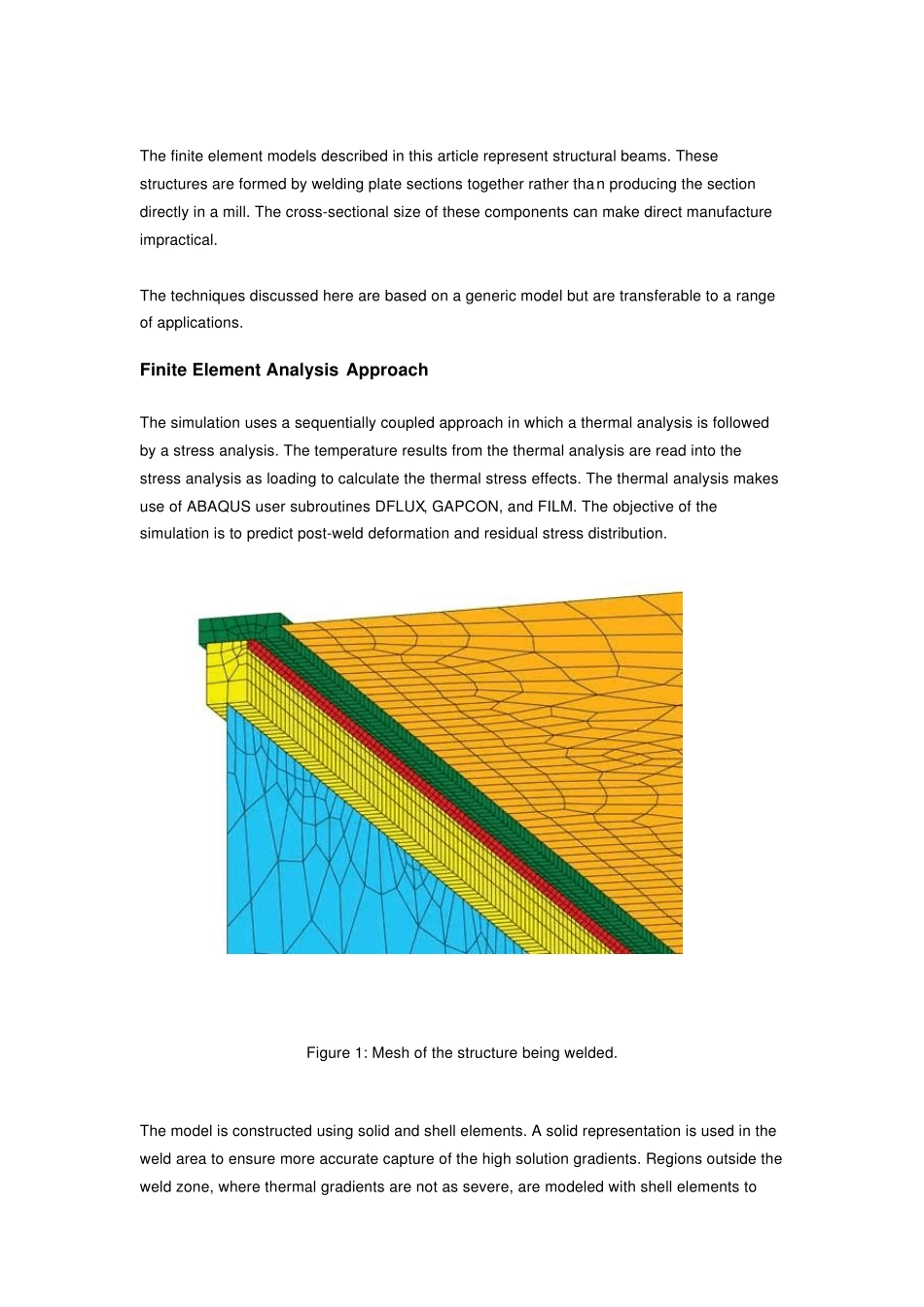

Low Stress Welding Simulations Welding is a fundamental manufacturing technique used to join metal components. While a variety of welding processes exist, most involve the application of heat to induce coalescence of the metal in the adjoining parts. The gas welding technique uses the heat from a gas flame to melt together the contacting edges of the parts being joined. A filler material may or may not be used. The introduction of very high temperatures in the region of the welded joint causes steep temperature gradients in the structure. As a weld cools, residual stresses may be produced in the weld zone; such stresses may cause the structure to distort. The ability to predict the residual stress state allows for the prediction of final part shapes and a more complete understanding of how residual stresses can affect the load capacity of a structure. The finite element models described in this article represent structural beams. These structures are formed by welding plate sections together rather than producing the section directly in a mill. The cross-sectional size of these components can make direct manufacture impractical. The techniques discussed here are based on a generic model but are transferable to a range of applications. Finite Element Analy sis Approach The simulation uses a sequentially coupled approach in which a thermal analysis is followed by a stress analysis. The temperature results from the thermal analysis are read into the stress analysis as loading to calculate the thermal stress effects. The thermal analysis makes use of ABAQUS user subroutines DFLUX, GAPCON, and FILM. The objective of the simulation is to predict post-weld deformation and residual stress distribution. F...