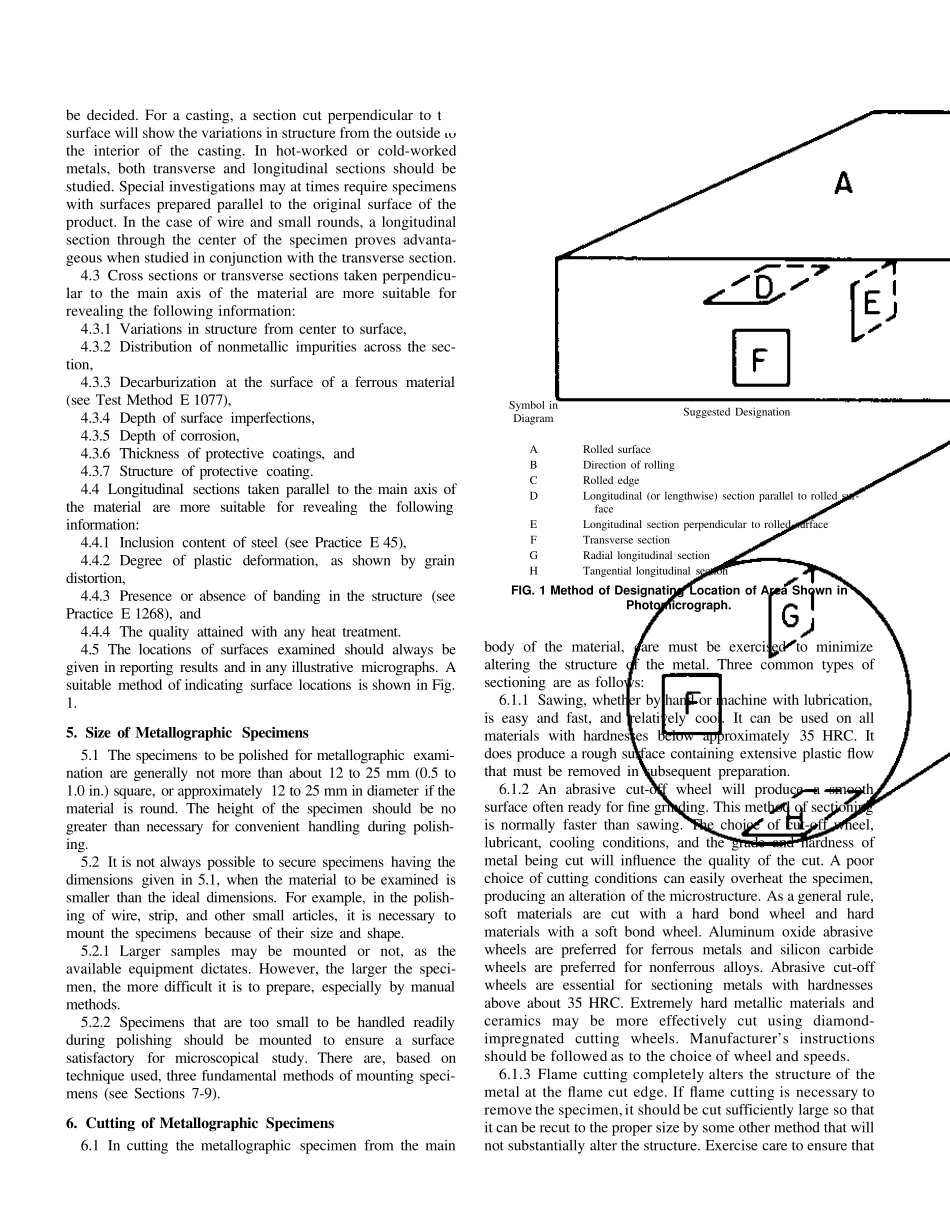

be decided. For a casting, a section cut perpendicular to thesurface will show the variations in structure from the outside tothe interior of the casting. In hot-worked or cold-workedmetals, both transverse and longitudinal sections should bestudied. Special investigations may at times require specimenswith surfaces prepared parallel to the original surface of theproduct. In the case of wire and small rounds, a longitudinalsection through the center of the specimen proves advanta-geous when studied in conjunction with the transverse section.4.3 Cross sections or transverse sections taken perpendicu-lar to the main axis of the material are more suitable forrevealing the following information:4.3.1 Variations in structure from center to surface,4.3.2 Distribution of nonmetallic impurities across the sec-tion,4.3.3 Decarburization at the surface of a ferrous material(see Test Method E 1077),4.3.4 Depth of surface imperfections,4.3.5 Depth of corrosion,4.3.6 Thickness of protective coatings, and4.3.7 Structure of protective coating.4.4 Longitudinal sections taken parallel to the main axis ofthe material are more suitable for revealing the followinginformation:4.4.1 Inclusion content of steel (see Practice E 45),4.4.2 Degree of plastic deformation, as shown by graindistortion,4.4.3 Presence or absence of banding in the structure (seePractice E 1268), and4.4.4 The quality attained with any heat treatment.4.5 The locations of surfaces examined should always begiven in reporting results and in any illustrative micrographs. Asuitable method of indicating surface locations is shown in Fig.1.5. Size of Metallographic Specimens5.1 The specimens to be polished for metallographic exami-nation are generally not more than about 12 to 25 mm (0...