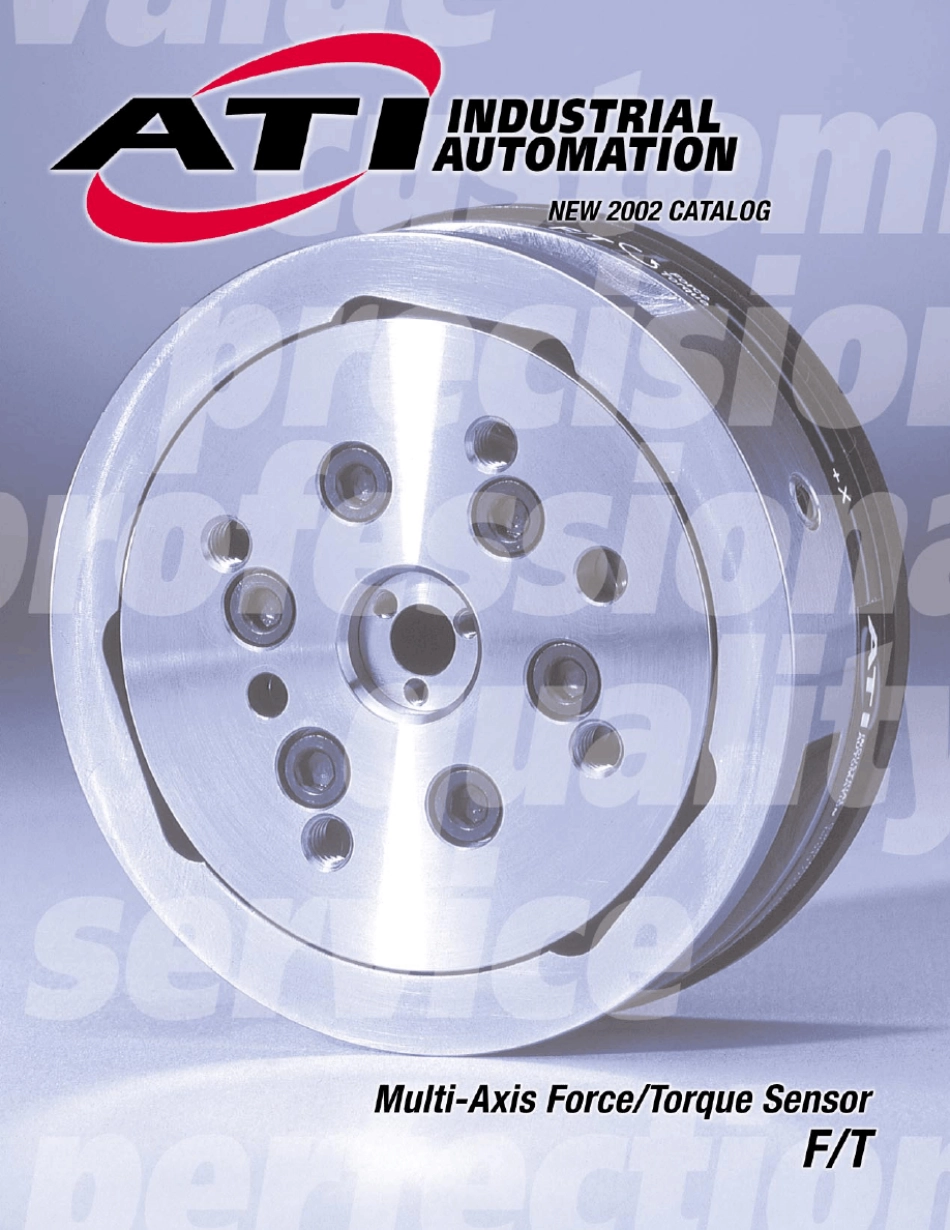

PRODUCT DESCRIPTIONThe F/T sensor system measures the full six componentsof force and torque (Fx, Fy, Fz, Tx, Ty, Tz) using amonolithic instrumented transducer. The F/T transduceruses silicon strain gauges for excellent noise immunity.The use of silicon gauges allows the F/T transducer to havehigh stiffness and increased overload protection. Alltransducer models are available with either DAQ F/T orController F/T interfaces.The DAQ F/T allows the transducer to connect to ananalog Data Acquisition (DAQ) card (PCI, USB, PCMCIA,etc.) making it easy to read sensor data with your PC orrobot controller. The F/T strain gauge signals areconditioned and transmitted to the DAQ card. Next, theATI DAQ software works with your computer to convertstrain gauge data into force/torque data. The DAQ F/Tconsists of a transducer, an interface board, a power supplyboard, a DAQ card, software and high-flex cables designedto shield against outside electrical noise.The Controller F/T processes the F/T strain gaugeinformation and outputs serial and analog force/torque data.Controller functions provide tool transformations, peakcapture, biasing and discrete I/O.BENE.ITS AND .EATURESOverload protectionThe F/T transducer is extremely rugged and durable. Thetransducer’s factor-of-safety can be as high as 2700%,depending on model and calibration.High signal-to-noise ratioSilicon gages provide a signal 75 times stronger thanconventional foil gages. This signal is amplified resulting innear-zero noise distortion.High-speed outputF/T controllers can output data at rates up to 28.5kHz.This speed exceeds requirements of most robotic and datacollection applications.Software Tool TransformationsTool transformations can translate and rotate the F/Treference frame.Versatile...