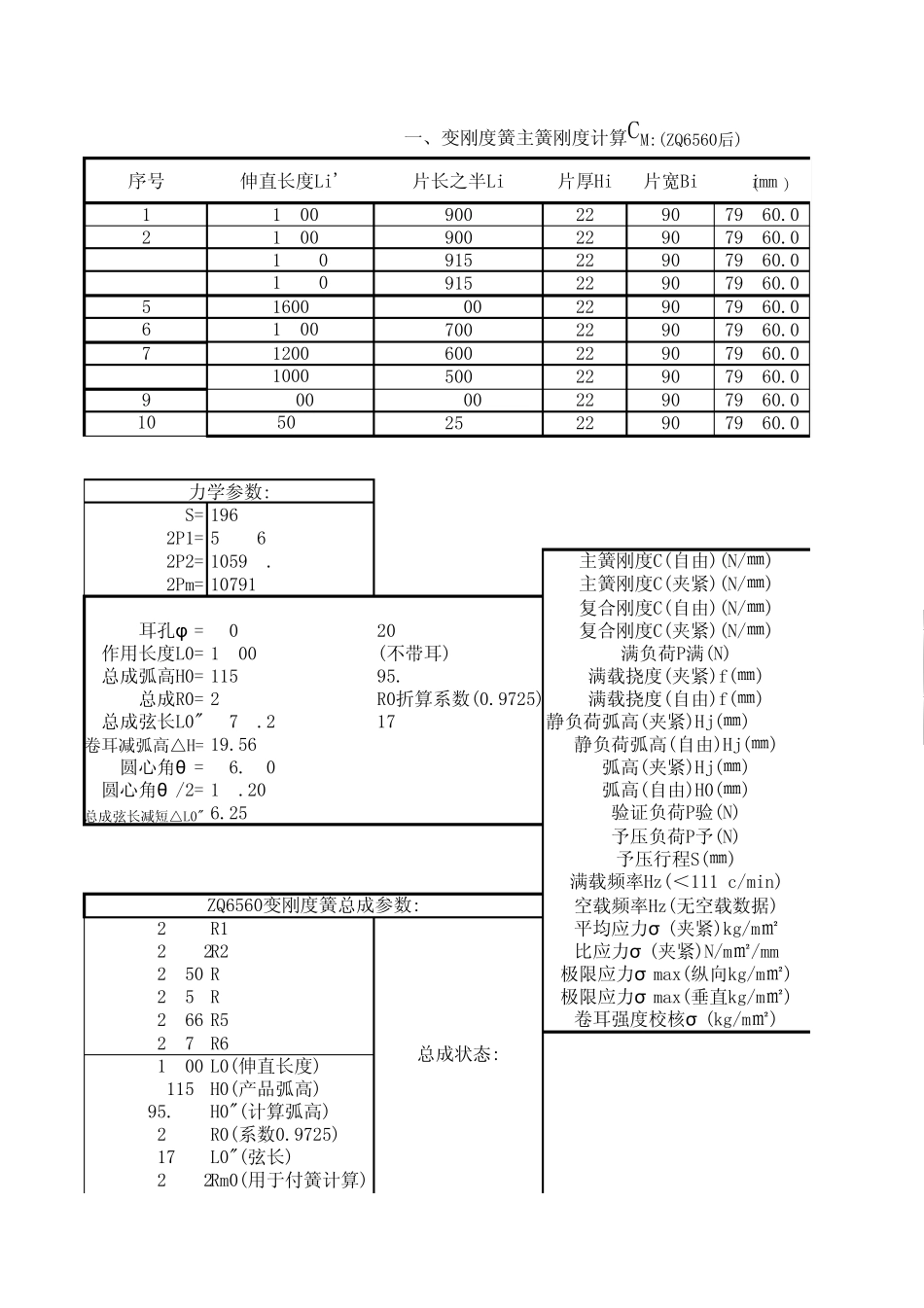

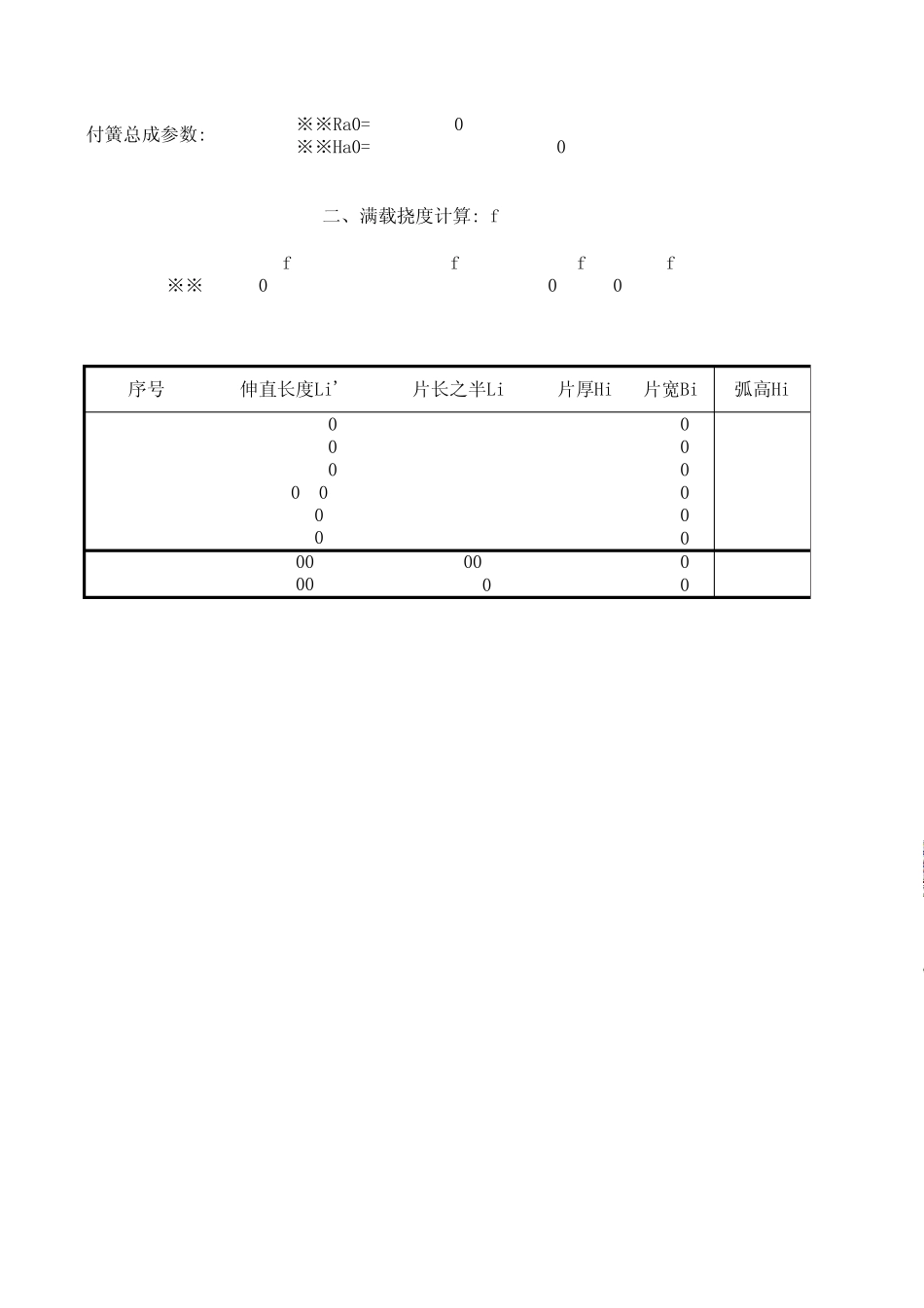

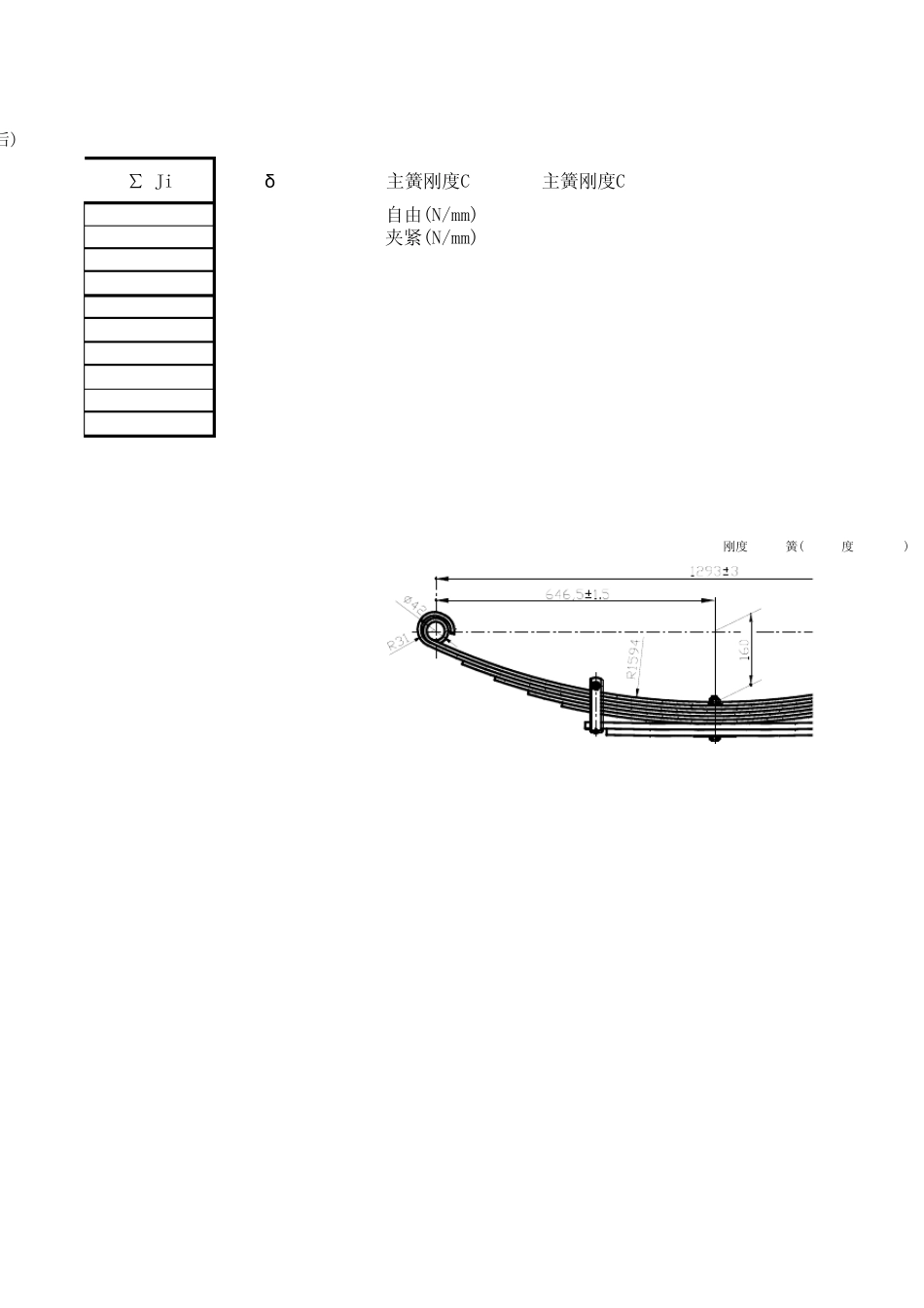

序号伸直长度Li'片长之半Li片厚Hi片宽BiJi(mm4)11800900229079860.021800900229079860.031830915229079860.041830915229079860.051600800229079860.061400700229079860.071200600229079860.081000500229079860.09800400229079860.010508254229079860.0S= 1962P1= 58862P2= 10594.82Pm= 10791耳孔φ = 4020作用长度L0= 1800(不带耳)总成弧高H0= 11595.44总成R0= 2834R0折算系数(0.9725)总成弦长L0" 874.241748静负荷弧高(夹紧)Hj(㎜)卷耳减弧高△H= 19.56圆心角θ = 36.40圆心角θ /2= 18.20总成弦长减短△L0" 6.252834R12842R22850 R32858R42866 R52874R61800 L0(伸直长度)115H0(产品弧高)95.44H0"(计算弧高)2834R0(系数0.9725)1748L0"(弦长)2882Rm0(用于付簧计算)ZQ6560变刚度簧总成参数:总成状态:空载频率Hz(无空载数据)平均应力σ (夹紧)kg/m㎡极限应力σ max(垂直kg/m㎡)比应力σ (夹紧)N/m㎡/mm极限应力σ max(纵向kg/m㎡)主簧刚度C(自由)(N/㎜)满载挠度(自由)f(㎜)静负荷弧高(自由)Hj(㎜)满载频率Hz(<111 c/min)验证负荷P验(N)予压负荷P予(N)弧高(夹紧)Hj(㎜)复合刚度C(自由)(N/㎜)满负荷P满(N)复合刚度C(夹紧)(N/㎜)主簧刚度C(夹紧)(N/㎜)予压行程S(㎜)卷耳强度校核σ (kg/m㎡)力学参数:一、变刚度簧主簧刚度计算CM:(ZQ6560后)满载挠度(夹紧)f(㎜)弧高(自由)H0(㎜)※※Ra0=3055※※Ha0=26.18353078f1f2f3f※※10.482993838.6184986590.18078219.2822711350675870213506758703119059587041030515870587043587067103558701600300147025002501470付簧总成参数:伸直长度Li'序号 二、满载挠度计算: f弧高Hi片宽Bi片厚Hi片长之半Li∑ Jiδ主簧刚度CM主簧刚度CM LM=L10 La=L1079860.01.163151365自由(N/mm)474.6746943900400159720.0夹紧(N/mm)561.4808225851351239580.0319440.0399300.0479160.0559020.0638880.0718740.0798600.0474.6746943561.4808225542.6641.010791142.930591319.2822742795.71772573115.0108777.3867145458.1333268.0548448216.04395886.8251391473.53959242833.543165后)ZQ6560多片渐变刚度钢板弹簧(伸直长度1350)弦长之半(Li"/2)668.63 1337.3668.67 1337.3590.68 1181.4512.22 1024.4433.33866.7354.10708.2弦长<弧长(伸直长度)弦长Li"La1=L11λ =LM-La35030025020012750050503012512011517845111板弹簧(伸直长度1350)复合刚度LM-La1 CM+a=1/5050735500.00339081542.61124501 0.00287044641.0 夹紧(N/mm)K(λ )m+a=K(λ )m+a1自由(N/mm)