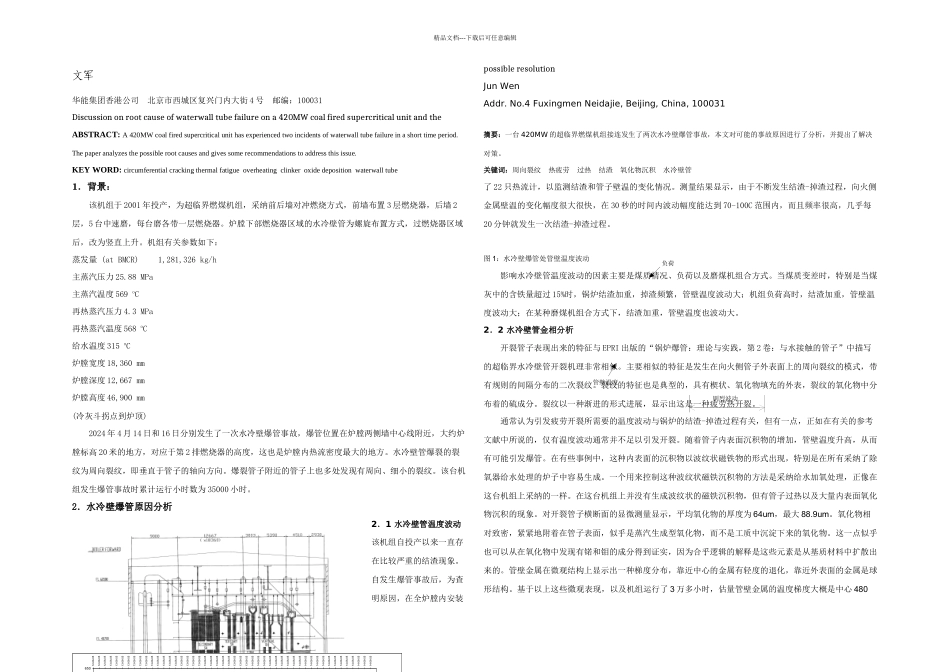

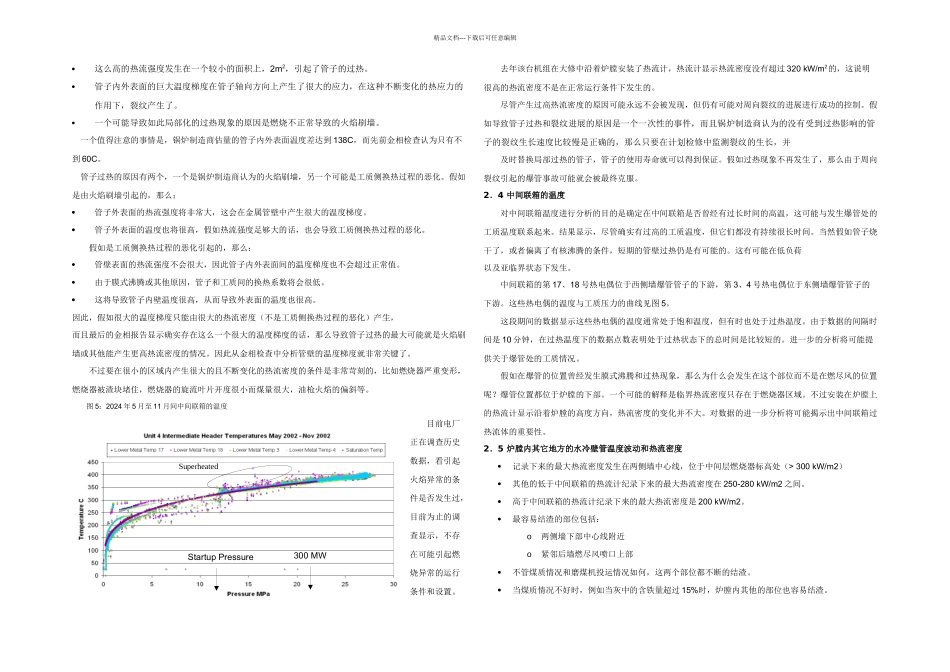

13815030035040045050055060065021:0022:0023:000:001:002:003:004:005:006:007:008:009:0010:0011:0012:0013:0014:0015:0016:0017:0018:0019:0020:0021:0022:0023:000:001:002:003:004:005:006:007:008:009:0010:0011:0012:0013:0014:0015:0016:0017:0018:0019:0020:00010020030040012-08-0512-08-0512-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0513-08-0514-08-0514-08-0514-08-0514-08-0514-08-0514-08-0514-08-0514-08-0514-08-0514-08-0514-08-0514-08-0514-08-0514-08-0514-08-0514-08-0514-08-0514-08-0514-08-0514-08-0514-08-05负荷精品文档---下载后可任意编辑文军华能集团香港公司 北京市西城区复兴门内大街 4 号 邮编:100031Discussion on root cause of waterwall tube failure on a 420MW coal fired supercritical unit and the possible resolutionJun WenAddr. No.4 Fuxingmen Neidajie, Beijing, China, 100031ABSTRACT: A 420MW coal fired supercritical unit has experienced two incidents of waterwall tube failure in a short time period. The paper analyzes the possible root causes and gives some recommendations to address this issue. KEY WORD: circumferential cracking thermal fatigue overheating clinker oxide deposition waterwall tube摘要:一台 420MW 的超临界燃煤机组接连发生了两次水冷壁爆管事故,本文对可能的事故原因进行了分析,并提出了解决对策。关键词:周向裂纹 热疲劳 过热 结渣 氧化物沉积 水冷壁管1.背景:该机组于 2001 年投产,为超临界燃煤机组,采纳前后墙对冲燃烧方式,前墙布置 3 层燃烧器,后墙 2层,5 台中速磨,每台磨各带一层燃烧器。炉膛下部燃烧器区域的水冷壁管为螺旋布置方式,过燃烧器区域后,改为竖直上升。机组有关参数如下:蒸发量 (at BMCR)1,281,326 kg/h主蒸汽压力 25.88 MPa主蒸汽温度 569 oC再热蒸汽压力 4.3 MPa再热蒸汽温度 568 oC给水温度 315 oC炉膛宽度 18,360 mm炉膛深度 12,667 mm炉膛高度 46,900 mm(冷灰斗拐点到炉顶)2024 年 4 月 14 日和 16 日分别发生了一次水冷壁...