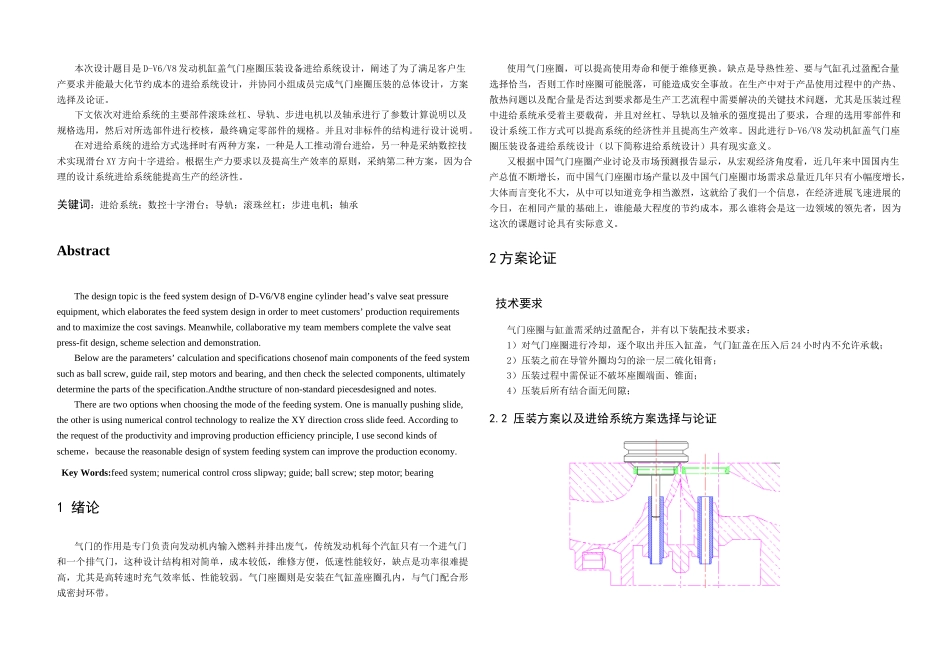

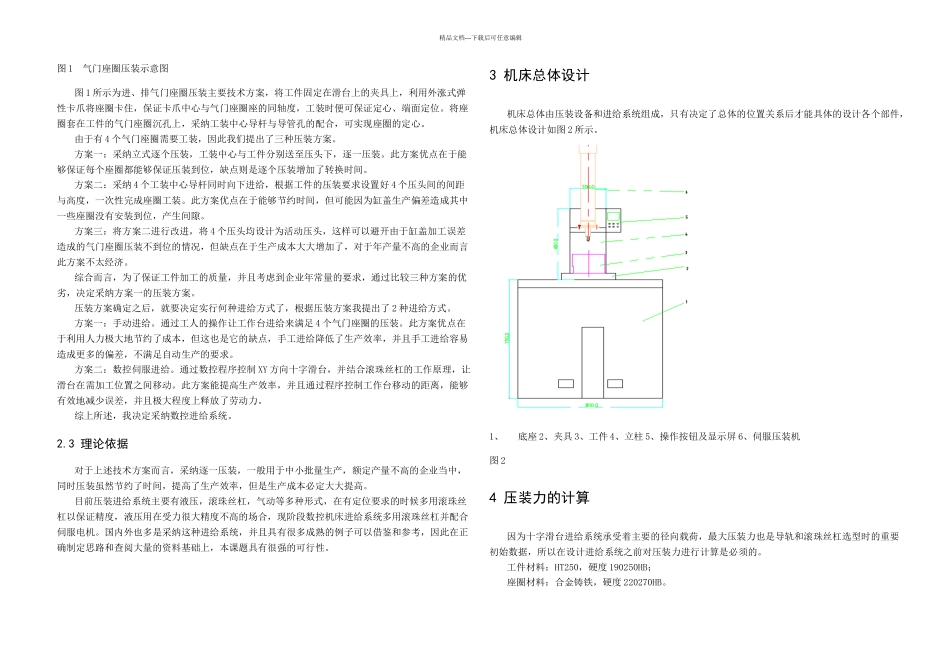

本次设计题目是 D-V6/V8 发动机缸盖气门座圈压装设备进给系统设计,阐述了为了满足客户生产要求并能最大化节约成本的进给系统设计,并协同小组成员完成气门座圈压装的总体设计,方案选择及论证。下文依次对进给系统的主要部件滚珠丝杠、导轨、步进电机以及轴承进行了参数计算说明以及规格选用,然后对所选部件进行校核,最终确定零部件的规格。并且对非标件的结构进行设计说明。在对进给系统的进给方式选择时有两种方案,一种是人工推动滑台进给,另一种是采纳数控技术实现滑台 XY 方向十字进给。根据生产力要求以及提高生产效率的原则,采纳第二种方案,因为合理的设计系统进给系统能提高生产的经济性。关键词:进给系统;数控十字滑台;导轨;滚珠丝杠;步进电机;轴承AbstractThe design topic is the feed system design of D-V6/V8 engine cylinder head’s valve seat pressure equipment, which elaborates the feed system design in order to meet customers’ production requirements and to maximize the cost savings. Meanwhile, collaborative my team members complete the valve seat press-fit design, scheme selection and demonstration.Below are the parameters’ calculation and specifications chosenof main components of the feed system such as ball screw, guide rail, step motors and bearing, and then check the selected components, ultimately determine the parts of the specification.Andthe structure of non-standard piecesdesigned and notes.There are two options when choosing the mode of the feeding system. One is manually pushing slide, the other is using numerical control technology to realize the XY direction cross slide feed. According to the request of the productivity and improving production efficiency principle, I use second kinds of scheme,because the reasonable design of system feeding system can improve the production economy.Key Words:feed system; numerical control cross slipway; guide; ball screw; step motor; bearing1 绪论气门的作用是专门负责向发动机...