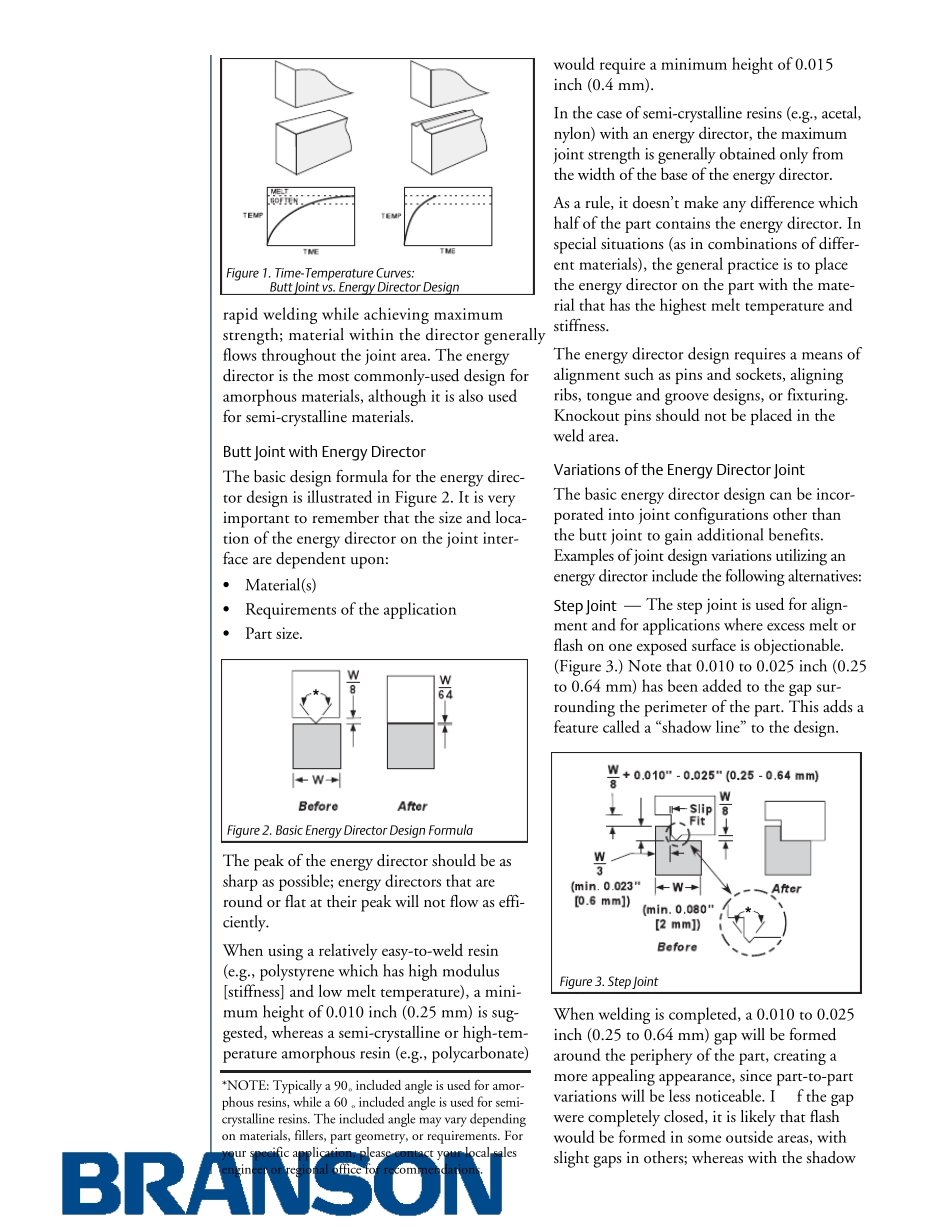

Ultrasonic energy has been used to join ther-moplastics for over 35 years. Ultrasonic weld-ing of thermoplastic materials is by far themost common form of ultrasonic assembly,and is used extensively in all major industriesincluding automotive, appliance, electronic,toy, packaging, textile, and medical. I t offersadvantages in speed, economy, and efficiency,and is frequently chosen when parts are toocomplex or expensive to be molded in onepiece.This bulletin provides guidelines to aid thedesigner during the initial concept stage of anew product design, ensuring optimum pro-duction results. The dimensions given in thedesigns should be used as guidelines only, sincethe specifics of your application may requirevariations. If you have questions or need assis-tance in designing your parts, contact yourlocal Branson representative, regional technicalcenter, or Branson headquarters in Danbury,Connecticut.Primary Factors Influencing JointDesignAll of the following basic questions must beanswered prior to the design stage to gain atotal understanding of what the weld jointmust do:•What type of material(s) is to be used?•What is the overall part size and configura-tion?•What are the final requirements of the part?-Is a structural bond desired and, if so,what load forces does it need to resist?-Is a hermetic seal required? If so, towhat pressure?-Does the assembly require a visuallyattractive appearance?-s flash or particulate objectionableinside and/or outside?-Any other requirements?Three Major Joint DesignCharacteristicsIn order to obtain acceptable, repeatable weld-ed joints, three general design guidelines mustbe followed:1. The initial contact area between the mat-ing surfaces should be smallto concen-trate and decrease the total energ...