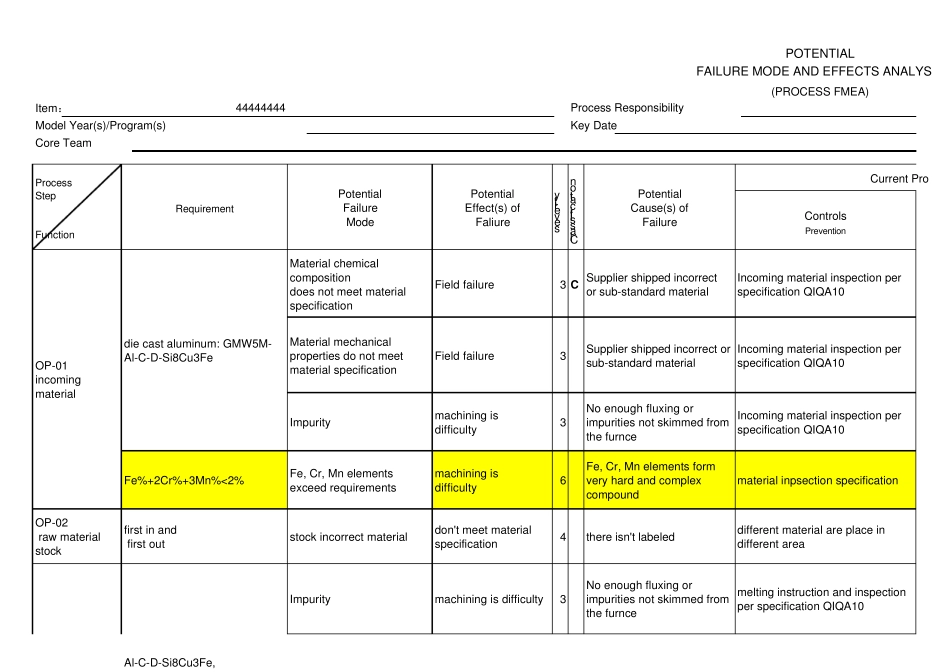

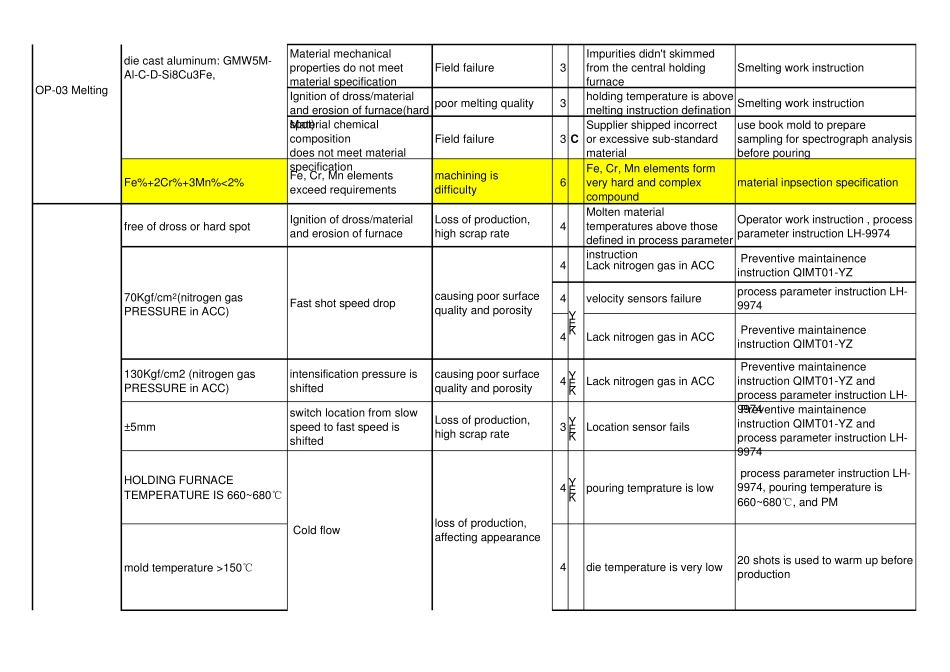

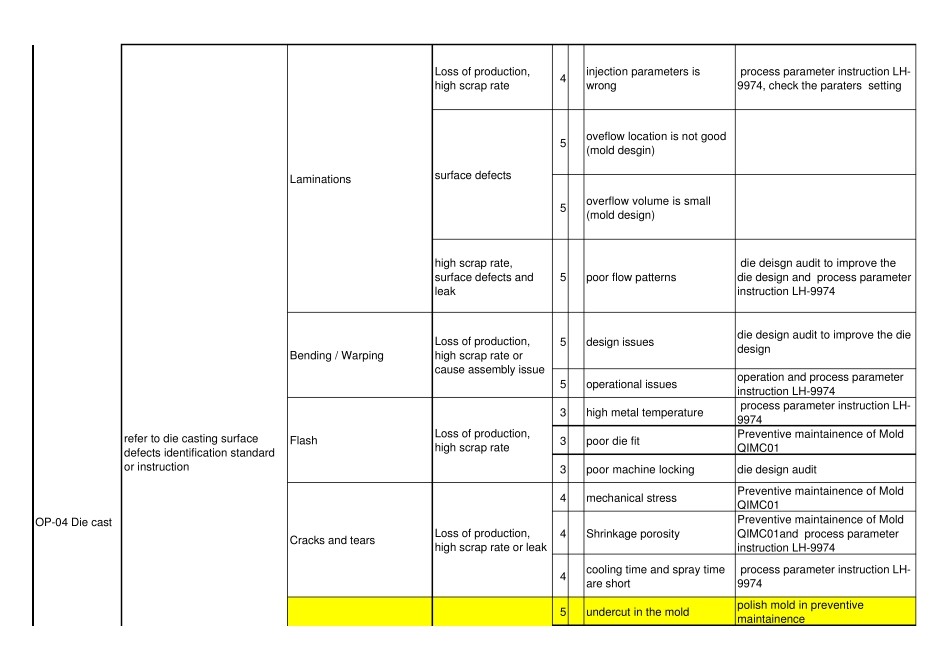

Item:44444444Process ResponsibilityModel Year(s)/Program(s)Key DateCore TeamControlsPreventionMaterial chemicalcompositiondoes not meet materialspecificationField failure3 C Supplier shipped incorrector sub-standard materialIncoming material inspection perspecification QIQA10Material mechanicalproperties do not meetmaterial specificationField failure3Supplier shipped incorrect orsub-standard materialIncoming material inspection perspecification QIQA10Impuritymachining isdifficulty3No enough fluxing orimpurities not skimmed fromthe furnceIncoming material inspection perspecification QIQA10Fe%+2Cr%+3Mn%<2%Fe, Cr, Mn elementsexceed requirementsmachining isdifficulty6Fe, Cr, Mn elements formvery hard and complexcompoundmaterial inpsection specificationOP-02 raw materialstockfirst in and first outstock incorrect materialdon't meet materialspecification4there isn't labeleddifferent material are place indifferent areaImpuritymachining is difficulty3No enough fluxing orimpurities not skimmed fromthe furncemelting instruction and inspectionper specification QIQA10OP-01incomingmaterialdie cast aluminum: GMW5M-Al-C-D-Si8Cu3FeAl-C-D-Si8Cu3Fe,ClassificationPOTENTIALFAILURE MODE AND EFFECTS ANALYS(PROCESS FMEA)Current ProPotentialCause(s) ofFailureProcessStep FunctionRequirementPotentialFailureModePotentialEffect(s) ofFaliureseverityMaterial mechanicalproperties do not meetmaterial specificationField failure3Impurities didn't skimmedfrom the central holdingfurnaceSmelting work instructionIgnition of dross/materialand erosion of furnace(hardspot)poor melting quality3holding temperature is abovemelting instruction defination Smelting work instructionMaterial chemicalcompositiondoes not meet materialspecificationField failure3 CSupplier shipped incorrector excessive sub-standardmaterialuse book mold to preparesampling for spectrograph...