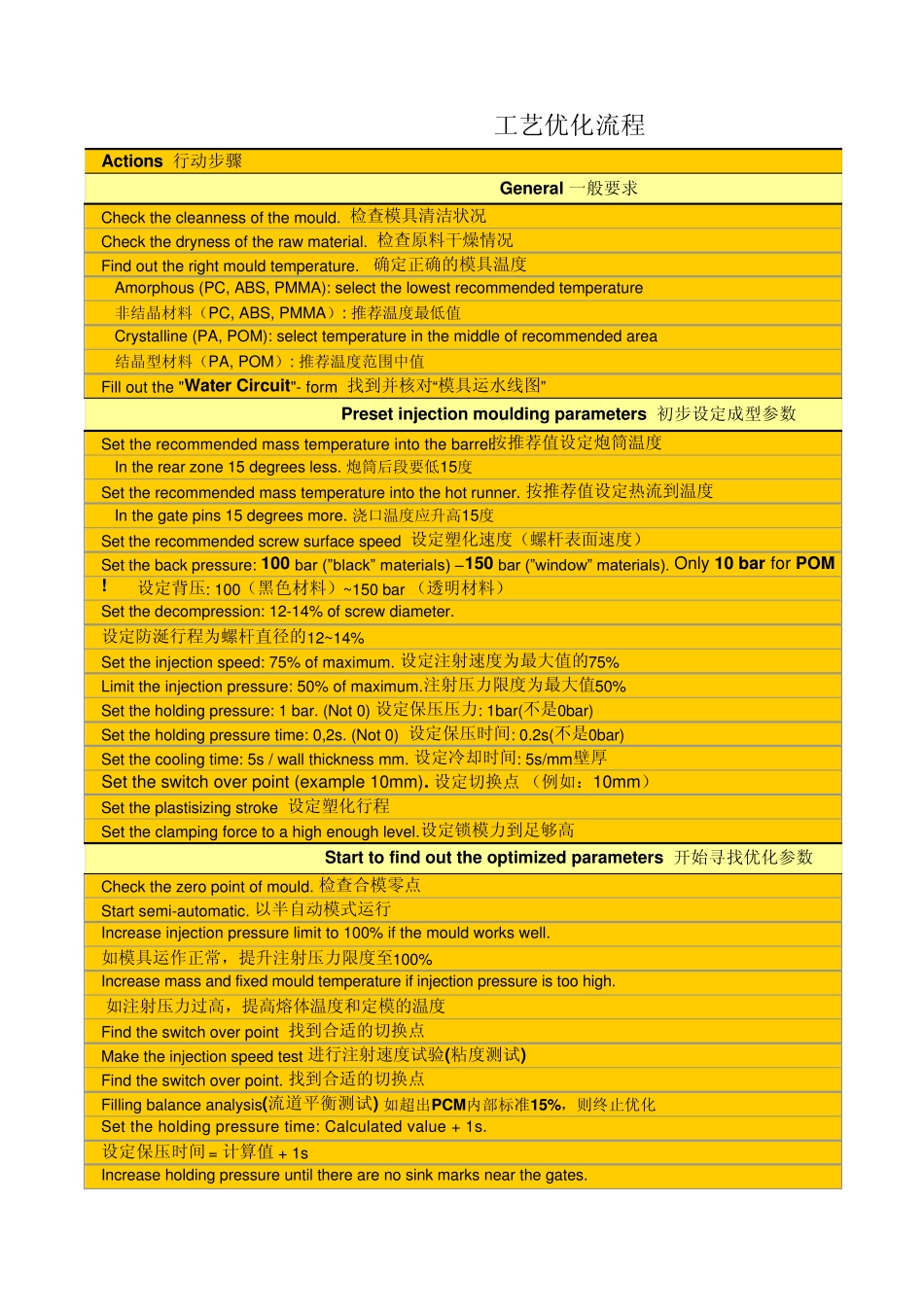

Step1.2.3.4.5.6.7.8.9.10.11.12.13.14.15.16.17.18.19.20.21.22.23.24.252627一般要求初步设定成型参数开始寻找优化参数2 82 93 03 13 23 33 4 .3 5 .3 6 .3 7 .3 83 94 0Actions 行动步骤Check the cleanness of the mould. 检查模具清洁状况Check the dryness of the raw material. 检查原料干燥情况Find out the right mould temperature. 确定正确的模具温度Amorphous (PC, ABS, PMMA): select the lowest recommended temperature非结晶材料(PC, ABS, PMMA): 推荐温度最低值Crystalline (PA, POM): select temperature in the middle of recommended area结晶型材料(PA, POM): 推荐温度范围中值Fill out the "Water Circuit"- form 找到并核对“模具运水线图”Set the recommended mass temperature into the barrel.按推荐值设定炮筒温度In the rear zone 15 degrees less. 炮筒后段要低15度Set the recommended mass temperature into the hot runner. 按推荐值设定热流到温度In the gate pins 15 degrees more. 浇口温度应升高15度Set the recommended screw surface speed 设定塑化速度(螺杆表面速度)Set the back pressure: 100 bar (” black” materials) – 150 bar (” window” materials). Only 10 bar for POM! 设定背压: 100(黑色材料)~150 bar (透明材料)Set the decompression: 12-14% of screw diameter.设定防涎行程为螺杆直径的12~14%Set the injection speed: 75% of maximum. 设定注射速度为最大值的75%Limit the injection pressure: 50% of maximum.注射压力限度为最大值50%Set the holding pressure: 1 bar. (Not 0) 设定保压压力: 1bar(不是0bar)Set the holding pressure time: 0,2s. (Not 0) 设定保压时间: 0.2s(不是0bar)Set the cooling time: 5s / wall thickness mm. 设定冷却时间: 5s/mm壁厚Set the switch over point (example 10mm). 设定切换点 (例如:10mm)Set the plastisizing stroke 设定塑化行程Set the clamping force to a high enough level.设定锁模力到足够高Check the zero point of mould. 检查合模零点Start semi-automatic. 以半自动模式运行Increase injection...