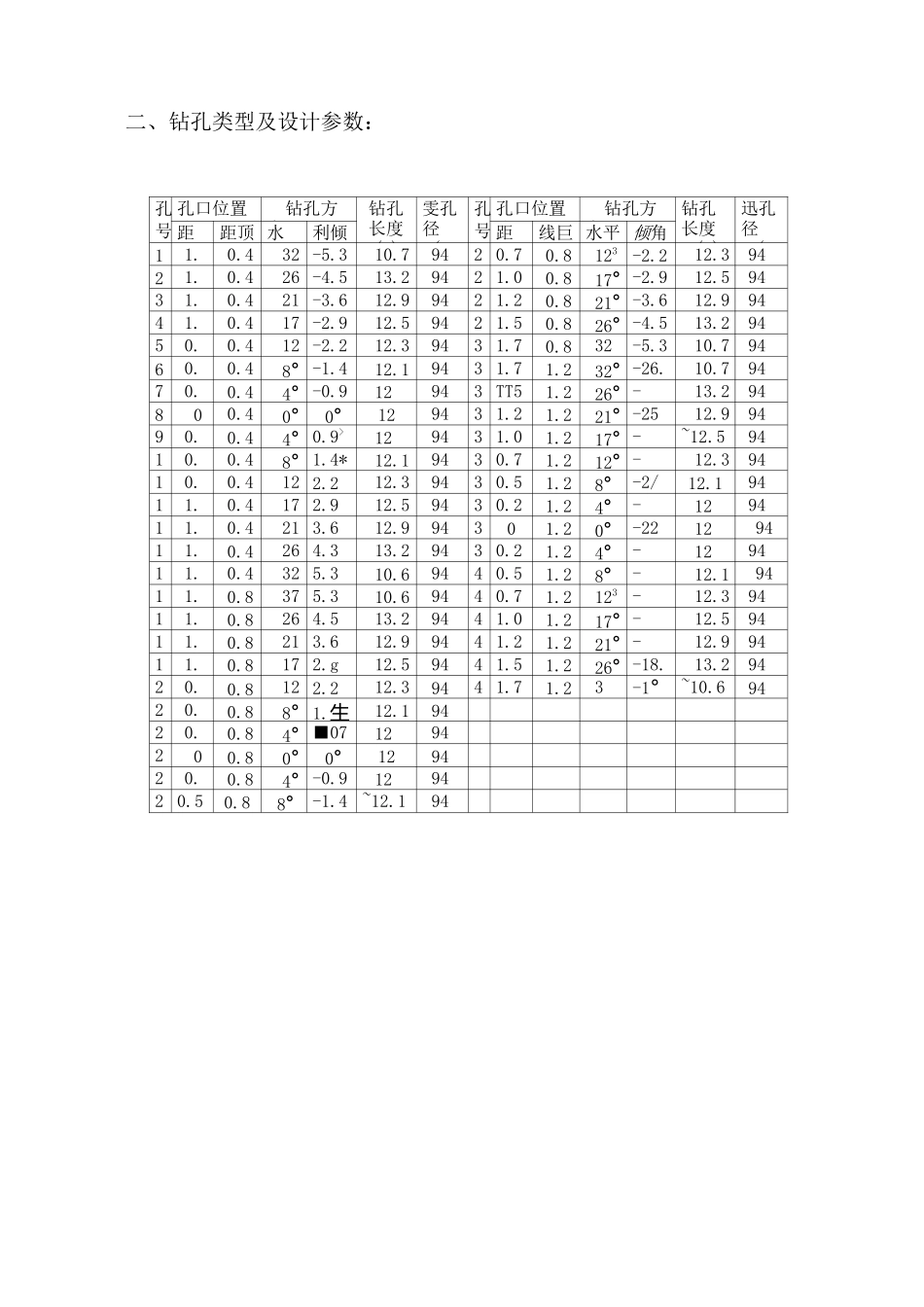

25091 运输巷人工打排放钻孔安全技术措施为加强局部综合防突措施,由我区在 25091 运输巷进行人工打超前瓦斯排放钻孔,为保证施工期间安全,特制定人工打超前瓦斯排放钻孔安全技术措施如下一、工钢支护断面排放钻孔布置示意图:(单位 mm)2、赫•妙3、2111ii3'd』P 产 89i0i1i2f3ii4i5:,8―r 晁畠 282726252423222i201$18 険:fi31323334353|3]3839404142434445■''25011、50001200036008,23-38二、钻孔类型及设计参数:孔号孔口位置m)钻孔方向钻孔长度(m)雯孔径(mm孔号孔口位置m)钻孔方向钻孔长度(m)迅孔径(mm距中距顶板水平利倾角距中线巨顶板水平角倾角11.750.432°-5.310.794260.750.8123-2.212.39421.500.426°-4.513.294271.000.817° -2.912.59431.250.421°-3.612.994281.250.821° -3.612.99441.000.417°-2.912.594291.500.826° -4.513.29450.750.4123-2.212.394301.750.832°-5.310.79460.500.48° -1.412.194311.751.232° -26.510.79470.250.44° -0.9129432TT501.226° -25.713.294800.40°0°1294331.251.221° -2512.99490.250.44° 0.9>1294341.001.217° -24.3~12.594100.500.48° 1.4*12.194350.751.212° -23.612.394110.750.41232.212.394360.501.28°-2/12.194121.000.417°2.912.594370.251.24°-22.51294131.250.421°3.612.9943801.20°-221294141.500.426°4.313.294390.251.24°-21.51294151.750.432 5.310.694400.501.28°-20.812.194161.750.837 5.310.694410.751.2123-20.312.394171.500.826°4.513.294421.001.217° -19.812.594181.250.821°3.612.994431.251.221° -19.412.994191.000.817°2.g12.594441.501.226° -18.113.294200.750.81232.212.394451.751.23労-1°~10.694210.500.88° 1.生12.194220.250.84° ■079^12942300.80°0°1294240.250.84° -0.91294250.500.88°-1.4~12.194说明:1、每掘进循环必须保留不少于 5m 的排放孔措施孔超前距和 2m 的效果检验超前距。2、排放钻孔控制正前方 12 米,孔径 94mm,孔数 45 个,第一排、第二排的钻孔平行煤层顶板;第三排的钻孔控制到巷道煤层底板 3.5m处,均按设计方向施工。3、排放钻孔控制巷道轮廓线外不小于 5m。三、安全技术措施:1、打钻地点必须放专职瓦斯检查员,严禁瓦斯超限作业,打钻人员必须听从瓦斯检查员的指挥。2、爱护通风设施,严禁随意移动风筒吊挂位置和改变风筒风流方向。3、工作人员必须随身...