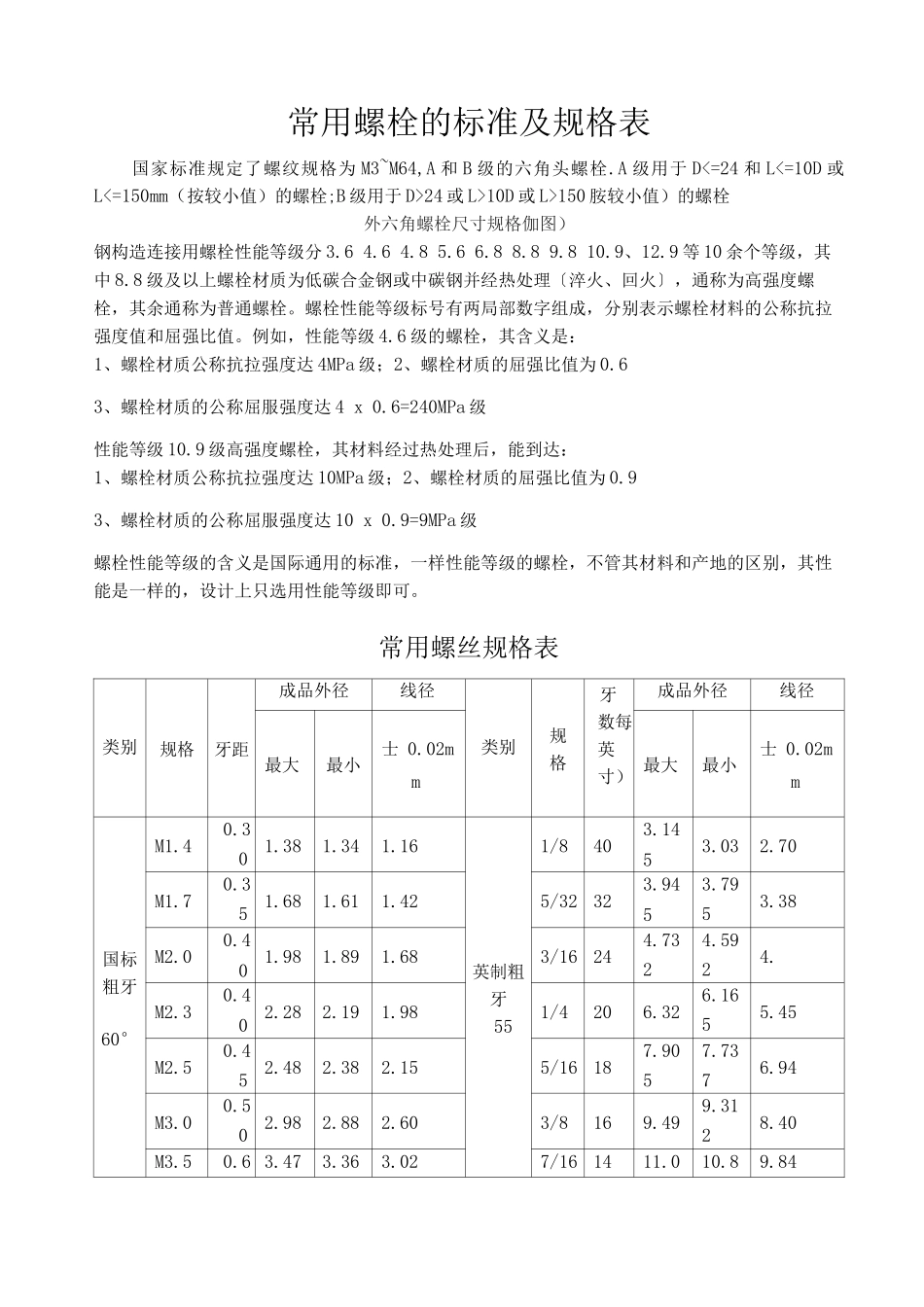

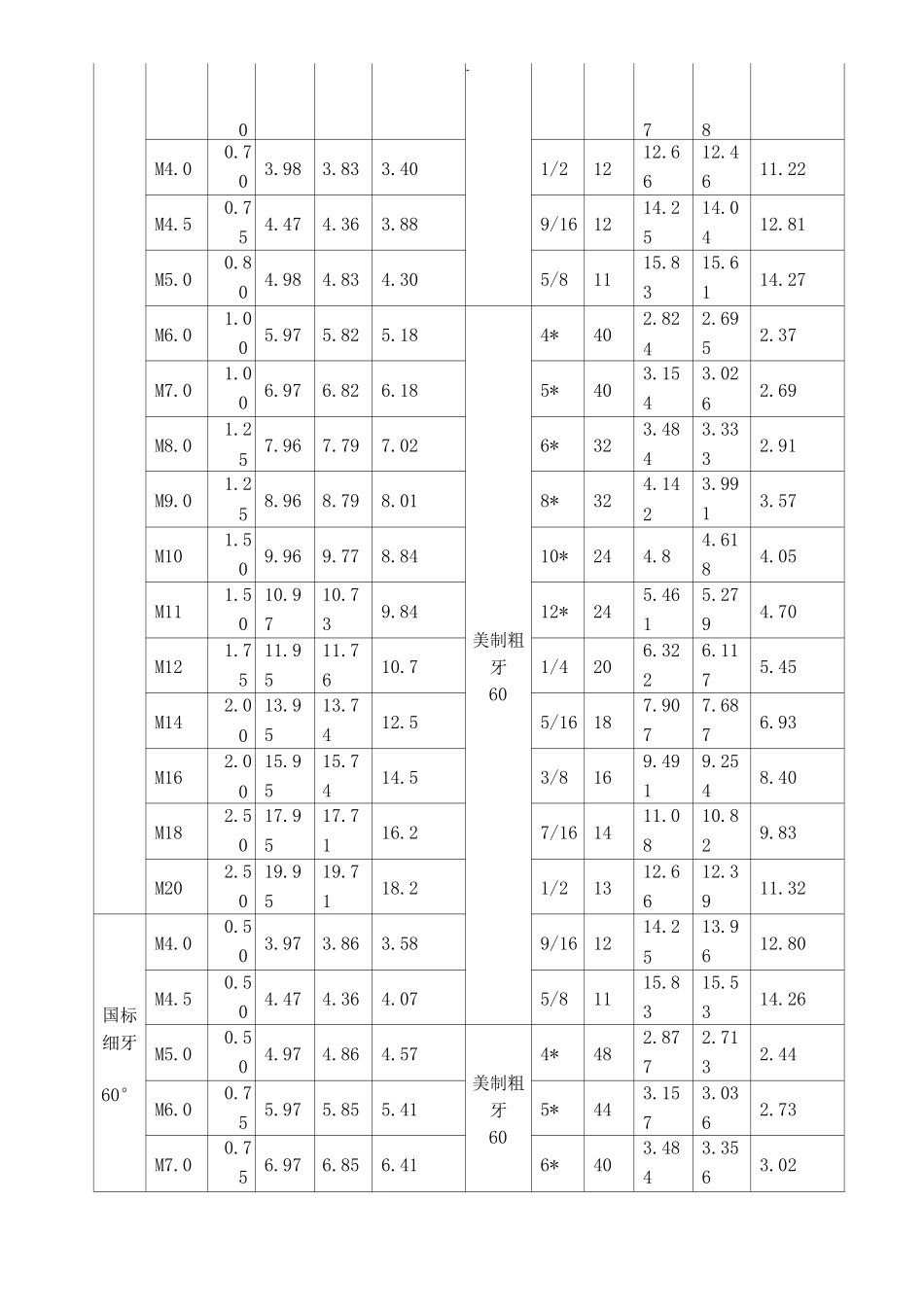

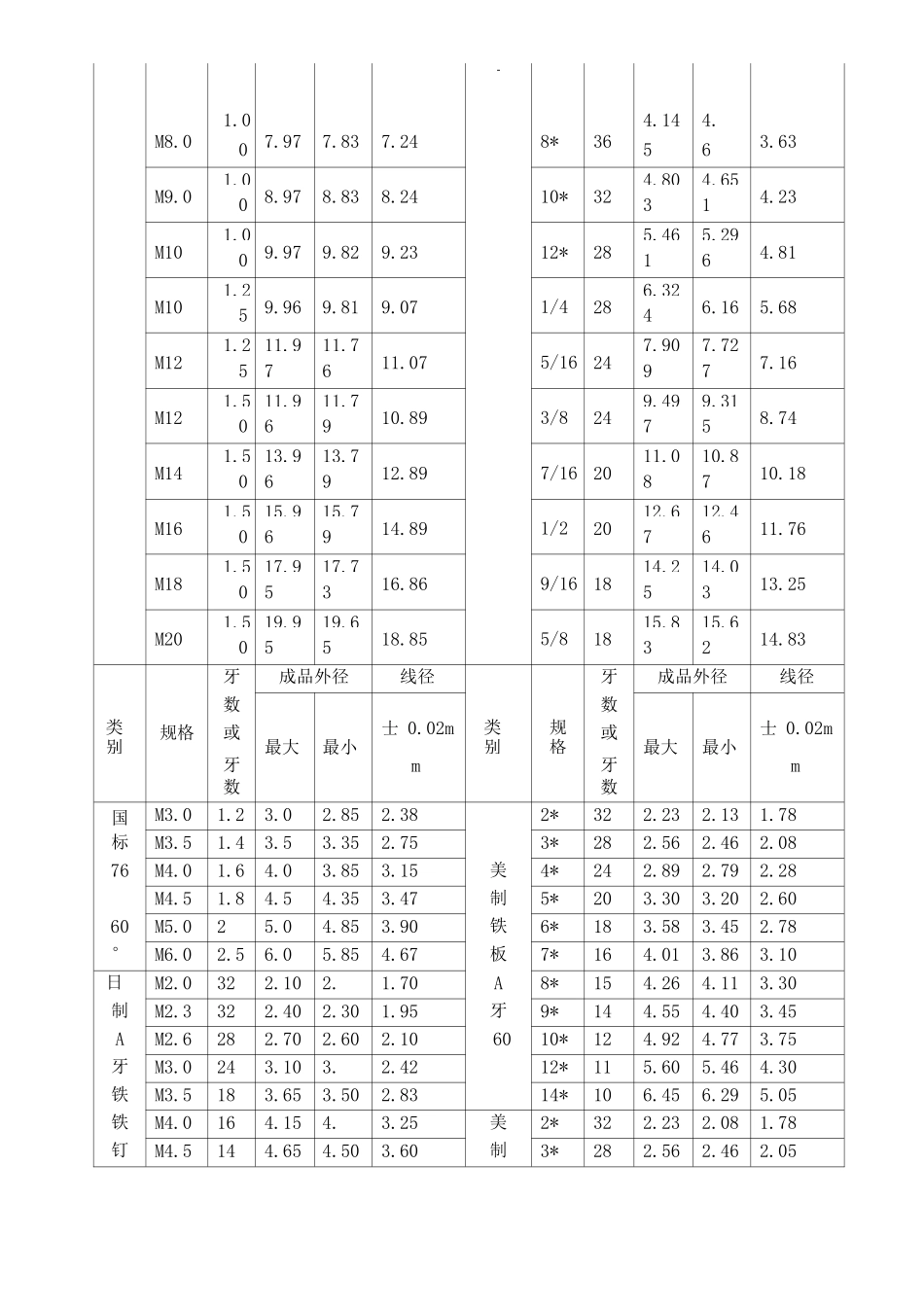

常用螺栓的标准及规格表国家标准规定了螺纹规格为 M3~M64,A 和 B 级的六角头螺栓.A 级用于 D<=24 和 L<=10D 或L<=150mm(按较小值)的螺栓;B 级用于 D>24 或 L>10D 或 L>150 胺较小值)的螺栓外六角螺栓尺寸规格伽图)钢构造连接用螺栓性能等级分 3.6 4.6 4.8 5.6 6.8 8.8 9.8 10.9、12.9 等 10 余个等级,其中 8.8 级及以上螺栓材质为低碳合金钢或中碳钢并经热处理〔淬火、回火〕,通称为高强度螺栓,其余通称为普通螺栓。螺栓性能等级标号有两局部数字组成,分别表示螺栓材料的公称抗拉强度值和屈强比值。例如,性能等级 4.6 级的螺栓,其含义是:1、螺栓材质公称抗拉强度达 4MPa 级;2、螺栓材质的屈强比值为 0.63、螺栓材质的公称屈服强度达 4 x 0.6=240MPa 级性能等级 10.9 级高强度螺栓,其材料经过热处理后,能到达:1、螺栓材质公称抗拉强度达 10MPa 级;2、螺栓材质的屈强比值为 0.93、螺栓材质的公称屈服强度达 10 x 0.9=9MPa 级螺栓性能等级的含义是国际通用的标准,一样性能等级的螺栓,不管其材料和产地的区别,其性能是一样的,设计上只选用性能等级即可。常用螺丝规格表类别规格牙距成品外径线径类别规格牙数每英寸)成品外径线径最大最小士 0.02mm最大最小士 0.02mm国标粗牙60°M1.40.301.381.341.16英制粗牙551/8403.1453.032.70M1.70.351.681.611.425/32323.9453.7953.38M2.00.401.981.891.683/16244.7324.5924.M2.30.402.282.191.981/4206.326.1655.45M2.50.452.482.382.155/16187.9057.7376.94M3.00.502.982.882.603/8169.499.3128.40M3.50.6 3.473.363.027/161411.010.89.840-78M4.00.703.983.833.401/21212.6612.4611.22M4.50.754.474.363.889/161214.2514.0412.81M5.00.804.984.834.305/81115.8315.6114.27M6.01.005.975.825.18美制粗牙604*402.8242.6952.37M7.01.006.976.826.185*403.1543.0262.69M8.01.257.967.797.026*323.4843.3332.91M9.01.258.968.798.018*324.1423.9913.57M101.509.969.778.8410*244.84.6184.05M111.5010.9710.739.8412*245.4615.2794.70M121.7511.9511.7610.71/4206.3226.1175.45M142.0013.9513.7412.55/16187.9077.6876.93M162.0015.9515.7414.53/8169.4919.2548.40M182.5017.9517.7116.27/161411.0810.829.83M202.5019.9519.7118.21/21312.6612.3911.32国标细牙60°M4.00.503.973.863.589/161214.2513.9612.80M4.50.504.474.364.075/81115.83...