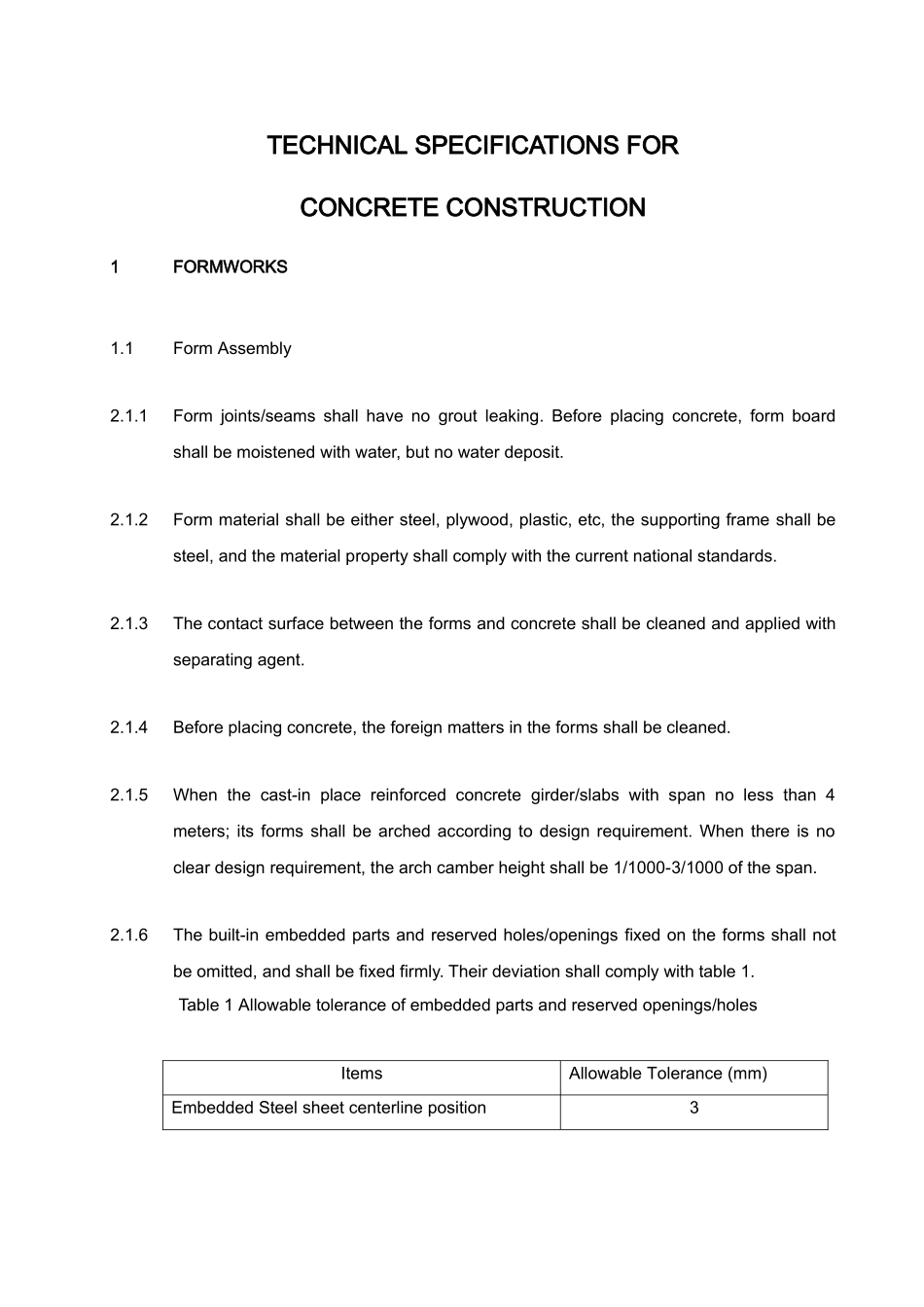

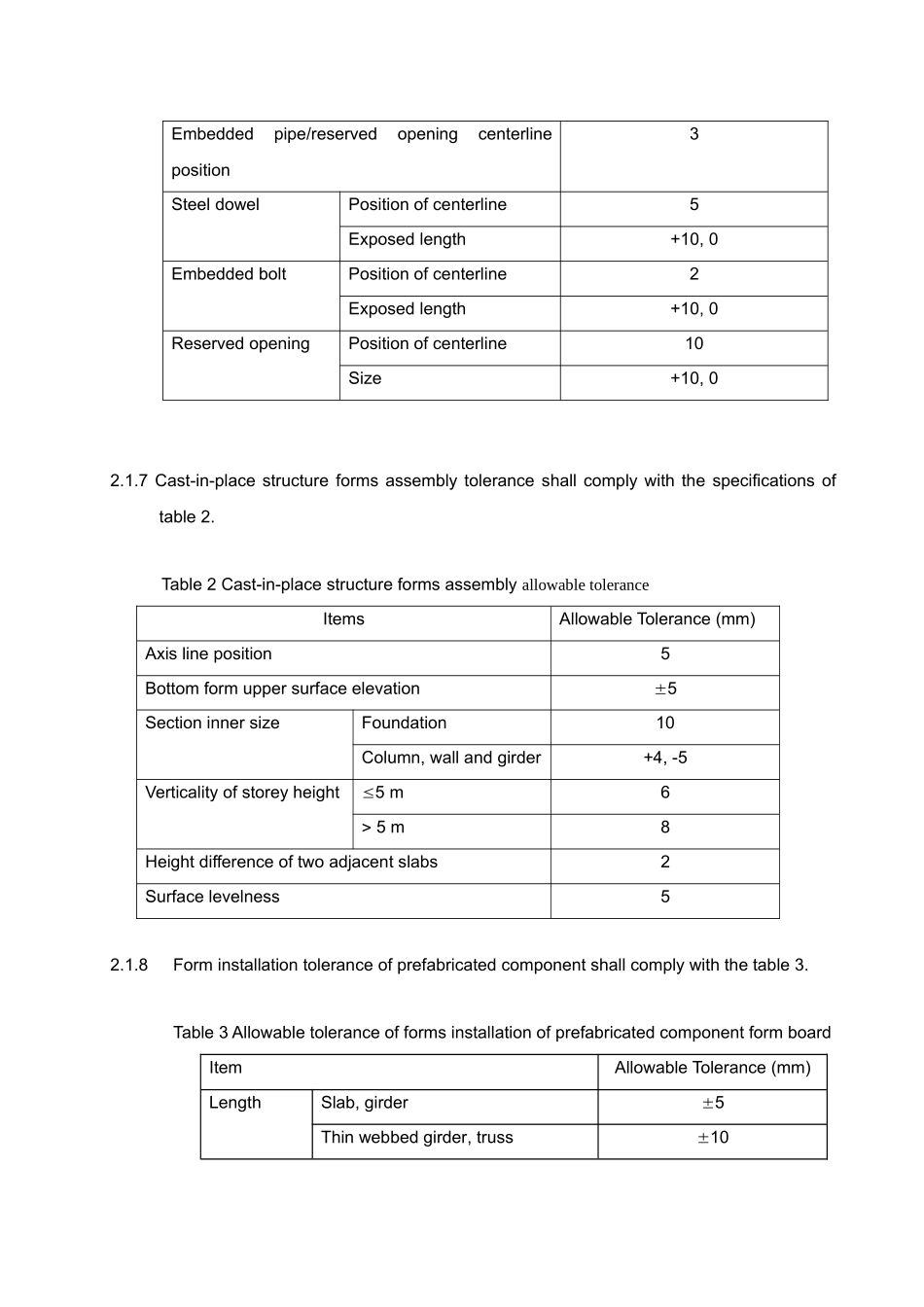

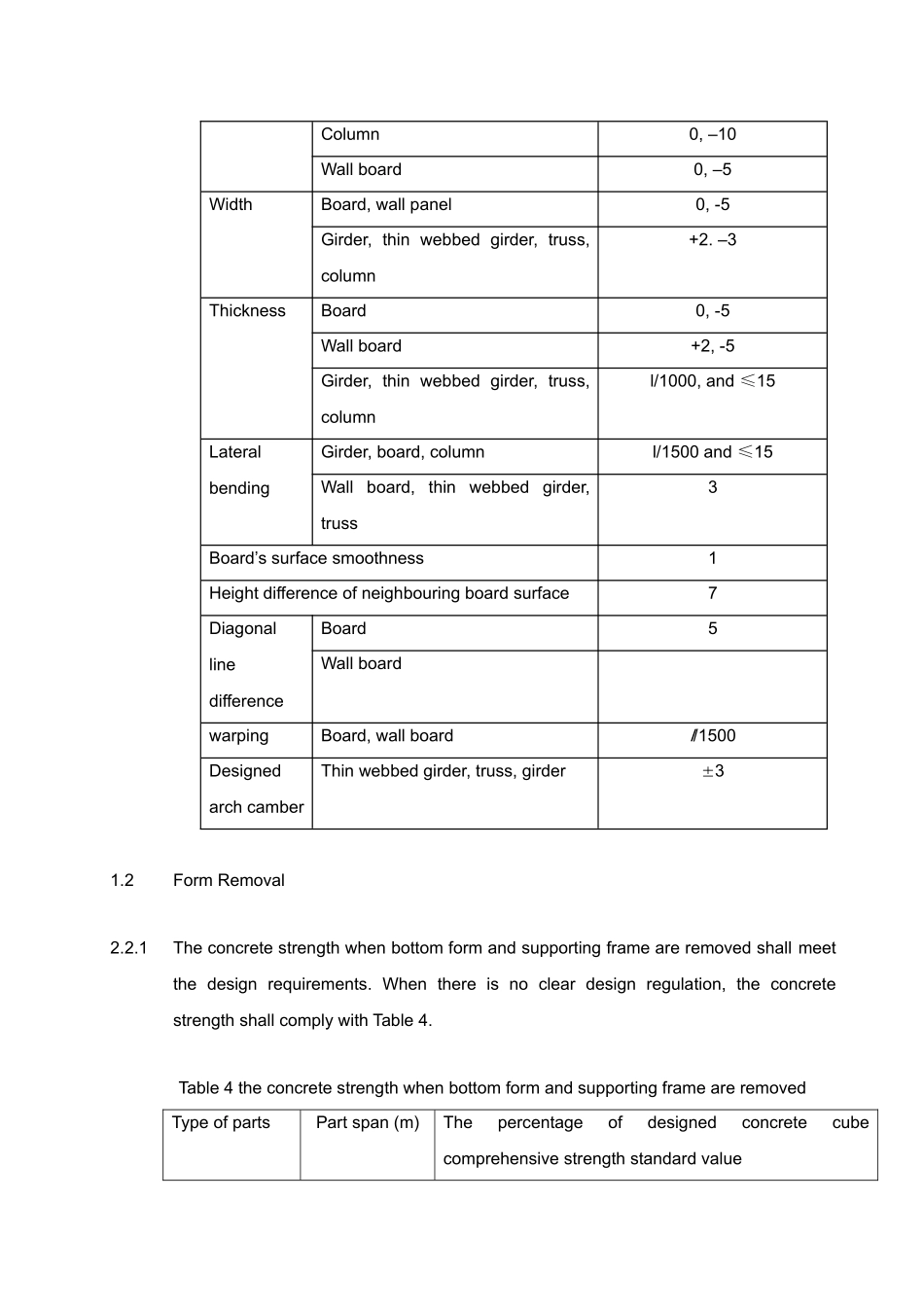

TECHNICAL SPECIFICATIONS FOR CONCRETE CONSTRUCTION1FORMWORKS1.1Form Assembly2.1.1Form joints/seams shall have no grout leaking. Before placing concrete, form board shall be moistened with water, but no water deposit. 2.1.2 Form material shall be either steel, plywood, plastic, etc, the supporting frame shall be steel, and the material property shall comply with the current national standards.2.1.3 The contact surface between the forms and concrete shall be cleaned and applied with separating agent.2.1.4 Before placing concrete, the foreign matters in the forms shall be cleaned.2.1.5 When the cast-in place reinforced concrete girder/slabs with span no less than 4 meters; its forms shall be arched according to design requirement. When there is no clear design requirement, the arch camber height shall be 1/1000-3/1000 of the span.2.1.6 The built-in embedded parts and reserved holes/openings fixed on the forms shall not be omitted, and shall be fixed firmly. Their deviation shall comply with table 1.Table 1 Allowable tolerance of embedded parts and reserved openings/holesItemsAllowable Tolerance (mm)Embedded Steel sheet centerline position3Embedded pipe/reserved opening centerline position3Steel dowelPosition of centerline5Exposed length+10, 0Embedded boltPosition of centerline2Exposed length+10, 0Reserved openingPosition of centerline10Size+10, 02.1.7 Cast-in-place structure forms assembly tolerance shall comply with the specifications of table 2.Table 2 Cast-in-place structure forms assembly allowable tolerance ItemsAllowable Tolerance (mm) Axis line position5Bottom form upper surface elevation5Section inner sizeFoundation10Column, wall and girder+4, -5Verticality of storey height 5 m6 5 m8Height difference of two adjacent slabs2Surfac...