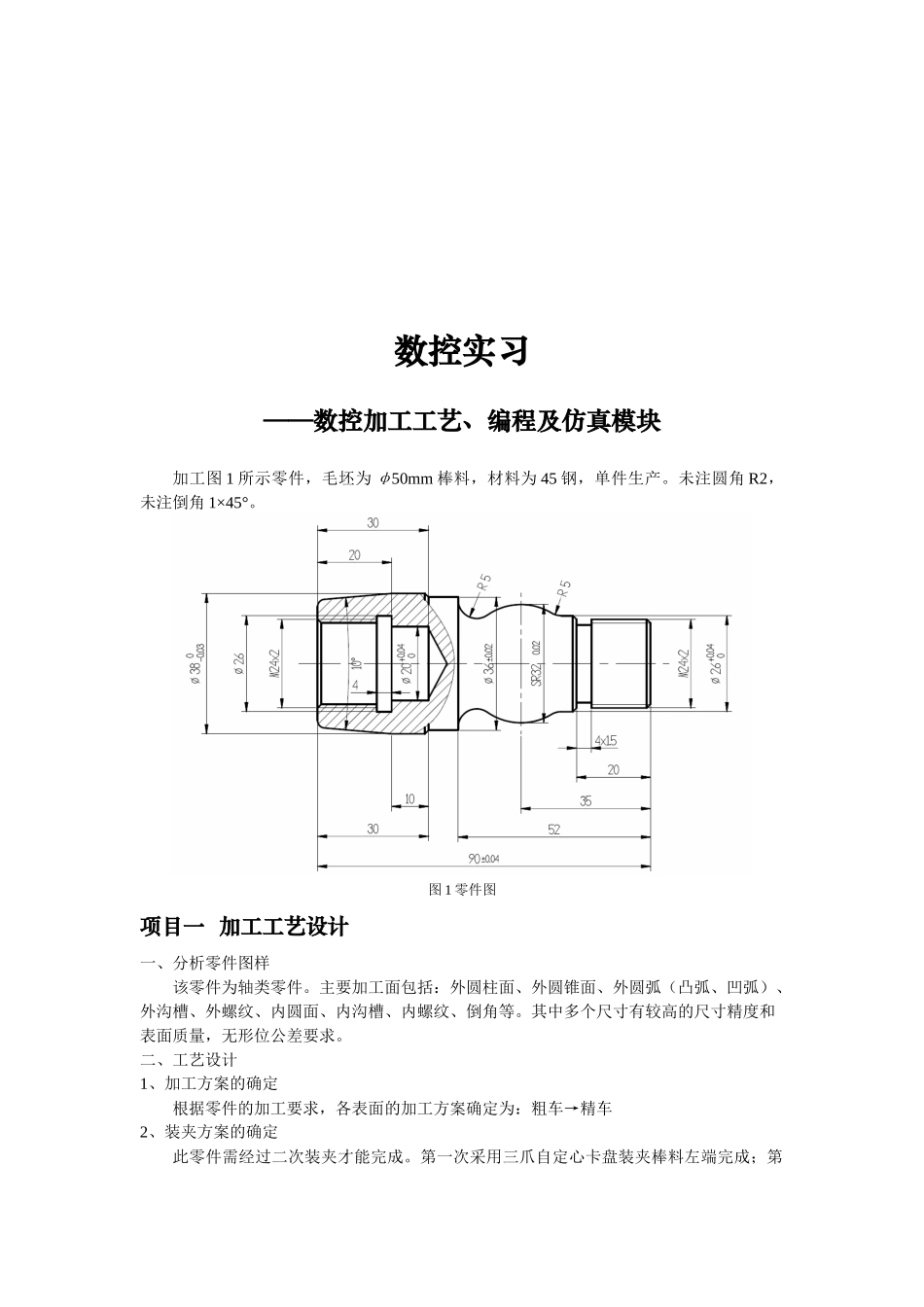

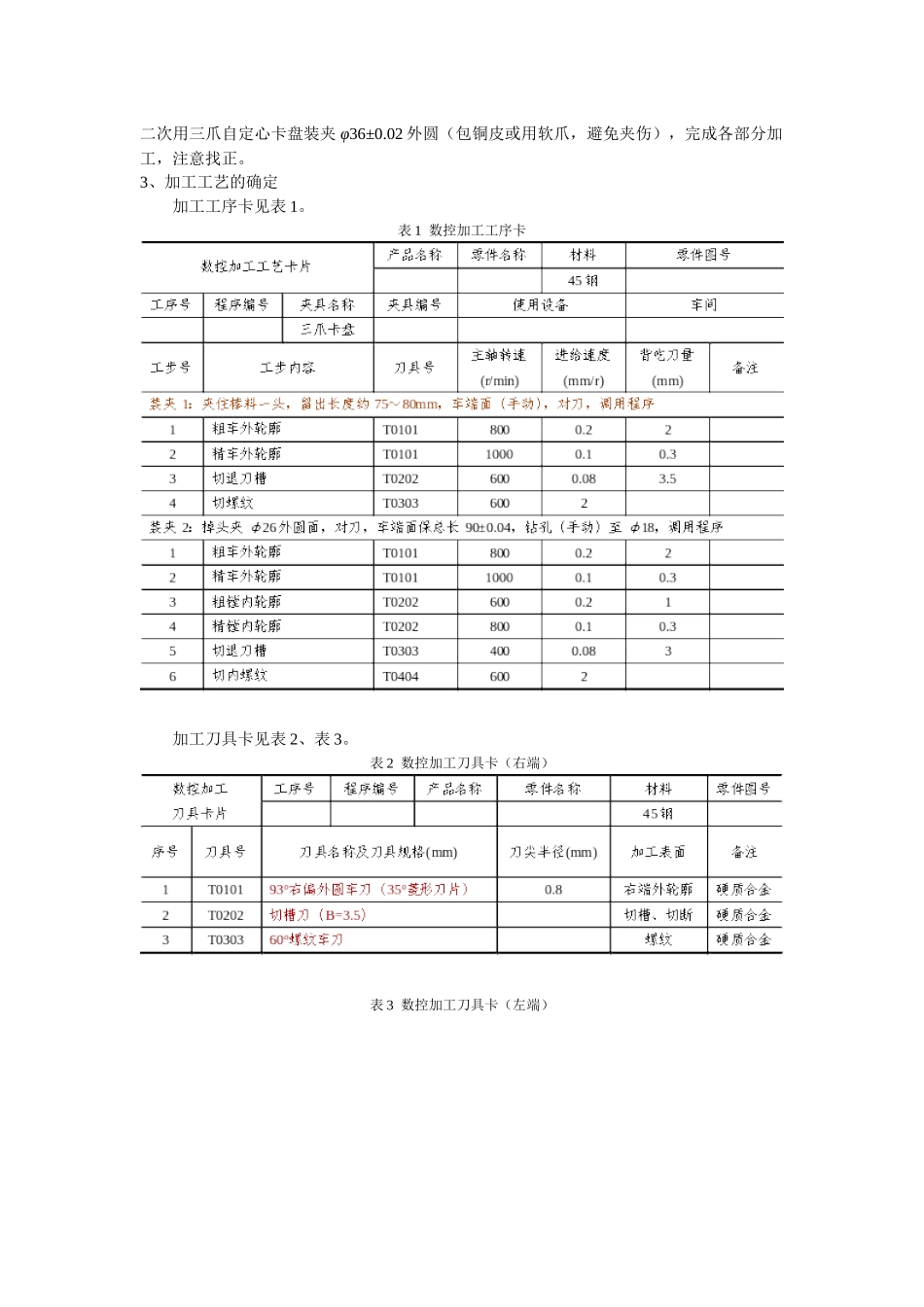

数控实习——数控加工工艺、编程及仿真模块加工图1所示零件,毛坯为φ50mm棒料,材料为45钢,单件生产。未注圆角R2,未注倒角1×45°。图1零件图项目一加工工艺设计一、分析零件图样该零件为轴类零件。主要加工面包括:外圆柱面、外圆锥面、外圆弧(凸弧、凹弧)、外沟槽、外螺纹、内圆面、内沟槽、内螺纹、倒角等。其中多个尺寸有较高的尺寸精度和表面质量,无形位公差要求。二、工艺设计1、加工方案的确定根据零件的加工要求,各表面的加工方案确定为:粗车→精车2、装夹方案的确定此零件需经过二次装夹才能完成。第一次采用三爪自定心卡盘装夹棒料左端完成;第二次用三爪自定心卡盘装夹φ36±0.02外圆(包铜皮或用软爪,避免夹伤),完成各部分加工,注意找正。3、加工工艺的确定加工工序卡见表1。表1数控加工工序卡加工刀具卡见表2、表3。表2数控加工刀具卡(右端)表3数控加工刀具卡(左端)项目二加工程序的编制一、FANUC手工编程1、工件坐标系的建立以工件右端面与轴线的交点为编程原点建立工件坐标系。2、编制程序程序见表4。表4参考程序%O2010(Right)#1=3.5T0101M03S800G00X55Z5X52Z2G90X46.6Z-71R0F0.2X42.6X38.6G01X41Z2S1000G90X38Z-70.8R0F0.1G73U6W0R3G73P1Q2U0.6W0.1F0.2S800N1G42G00X18G01X24Z-1F0.1S1000Z-20X26Z-21Z-24.183G02X27.429Z-26.759R5G03X26.261Z-44.143R18G02X34.467Z-52R5G01X36Z-60N2X40Z-62程序名切槽刀刀宽B=3.5mm选择1号刀1号刀补启动主轴快进至进刀点快进至G90车削循环起点G90去除外轮廓余量G73循环粗加工外轮廓建立刀尖圆弧半径补偿G70P1Q2G40G00X100Z100M05T0100T0202M03S600G00X28Z-20G01X21F0.08X28Z-[#1+16]X21X28G00X100Z100M05T0200T0303M03S600G00X30Z5G01X28G92X23.2Z-18F2X22.6X22X21.6X21.4G00X100Z100M05T0300M30%G70循环精加工外轮廓X向退刀,取消刀尖圆弧半径补偿Z向快速退刀至换刀点,主轴停取消1号刀刀补选择2号刀2号刀补取消2号刀刀补选择3号刀3号刀补取消3号刀刀补程序结束%O2011(Left)#1=3#2=38-40*TAN[5]#3=38+2*TAN[5]T0101M03S800G00X55Z5G01X52Z2F0.2G73U8R4G73P1Q2U0.6W0.1N1G42G00X30G01Z0X#2R2程序名切槽刀刀宽B=3mm选择1号刀1号刀补启动主轴快进至进刀点快进至G73复合循环起点G73循环粗加工外轮廓建立刀尖圆弧半径补偿N2X#3Z-21G70P1Q2F0.1S1000G40G00X100Z200M05T0100T0202M03S600G00X55Z5G01X15Z2F0.2G71U1R1G71P3Q4U-0.6W0.1F0.1N3G00X28G01X22Z-1Z-20X20Z-30N4X15G70P3Q4F0.1S1000G00Z200X100M05T0200T0303M03S600G00X55Z5G01X19Z2Z-20X26F0.08X19Z-[#1+16]X26F0.08X19Z2G00Z200X100M05T0300T0404M03S600G00X55Z5G01X20G92X22.4Z-18F2X22.8X23.2X23.6G70循环精加工外轮廓X向退刀,取消刀尖圆弧半径补偿Z向快速退刀至换刀点,主轴停取消1号刀刀补选择2号刀2号刀补工进至G71复合循环起点G71循环粗加工内轮廓G70循环精加工内轮廓Z向退刀X向快速退刀至换刀点,主轴停取消2号刀刀补选择3号刀3号刀补取消3号刀刀补选择4号刀4号刀补X23.8X24G00Z200X100M05T0400M30%取消4号刀刀补程序结束二、Mastercam自动编程1、Mastercam零件图纸的绘制图2Mastercam中绘制的零件图2、自动生成FANUC后处理程序(部分)%O0000(PROGRAMNAME-T201006)(DATE=DD-MM-YY-22-11-11TIME=HH:MM-22:24)(MCXFILE-E:\SUN7111\数控工艺员\2010\T201006.MCX-5)(NCFILE-E:\SUN7111\数控工艺员\T201006.NC)(MATERIAL-IRONMM-CAST-DUCTILE-AUSTENSITIC-160BHN)G21(TOOL-1OFFSET-1)(ODROUGHRIGHT-80DEG.INSERT-CNMG120408)G0T0101G18G97S350M03G0G54X52.Z5.X52.262Z2.108G99G1X-1.6F.2G0Z2.608X52.262Z1.254G1X-1.6G0Z1.754X52.262Z.4G1X-1.6G0Z.9X52.262Z0.G1X-1.6G0Z.5X52.Z5.G28U0.V0.W0.M05T0100M01(TOOL-2OFFSET-2)(CENTERDRILL-6.DIA.)G0T0202G18G97S557M03G0G54X0.Z5.Z2.G1Z-4.F.32G0Z5.G28U0.V0.W0.M05T0200M01(TOOL-3OFFSET-3)(DRILL20.DIA.)G0T0303G18G97S175M03G0G54X0.Z5.Z2.G1Z-36.F.32G0Z5.G28U0.V0.W0.M05T0300M01……M01(TOOL-8OFFSET-8)(ODTHREADRIGHT-MEDIUMINSERT-R166.0G-16MM01-150)G0T0808G18G97S640M03G0G54X28.Z5.G76P010000Q0.R0.G76X21.4Z-18.P13000Q5144R0.E2.X100.Z100.G28U0.V0.W0.M05T0800M30%项目三加工仿真一、斯沃仿真结果仿真加工后的零件见图3所示。(a)俯视图(b)剖视图图3斯沃仿真加工完成的零件二、Mastercam仿真结果仿真加工后的零件见图4所示。(a)俯视图(b)剖视图(c)刀轨图图4Mastercam仿真加工完成的零件