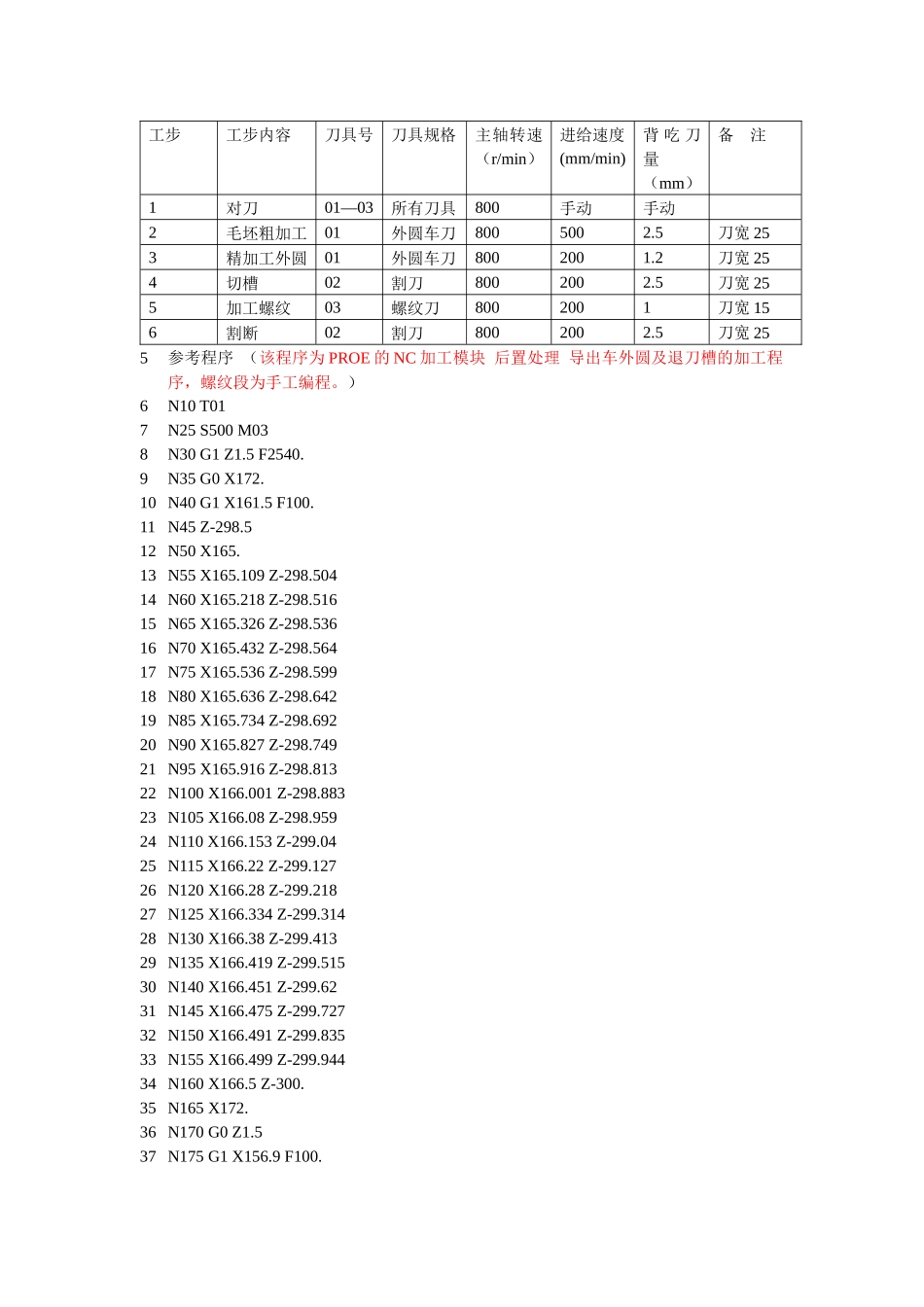

数控机床仿真实验报告班级:姓名:学号:指导老师:实验日期:实验一数控车床操作加工仿真实验一、实验目的(1)掌握手工编程的步骤;(2)掌握数控加工仿真系统的操作流程。二、实验内容(1)了解数控仿真软件的应用背景;(2)掌握手工编程的步骤;(3)掌握SEMENS802cT数控加工仿真操作流程。三、实验设备(1)图形工作站;(2)南京宇航数控加工仿真软件四、实验操作步骤1、实验试件试件的形状、尺寸如图1-1所示。工件信息棒料直径:165.000长度:500.000材料:10低碳钢2、加工采用的刀具参数刀具及相关参数如表1-1所列刀具号刀具名称零件材料为铝材刀具圆角半径补偿值(mm)备注转速(r/min)进给量(mm/min)01外圆车刀800500手动刀宽25MM02割刀500500手动加工退刀槽03螺纹刀500500手动加工螺纹3、工序卡片根据零件材料、加工精度、工艺路线、刀具参数表和切削用量等内容,确定加工工序卡,如表1-2所列。表1-2数控车削加工工序卡单位名称产品名称零件名称零件图号数控车削实验件轴11工序号程序编号夹具名称使用设备工作地点001三爪卡盘数控车铣综合实验台CAD/CAM(2)工步工步内容刀具号刀具规格主轴转速(r/min)进给速度(mm/min)背吃刀量(mm)备注1对刀01—03所有刀具800手动手动2毛坯粗加工01外圆车刀8005002.5刀宽253精加工外圆01外圆车刀8002001.2刀宽254切槽02割刀8002002.5刀宽255加工螺纹03螺纹刀8002001刀宽156割断02割刀8002002.5刀宽255参考程序(该程序为PROE的NC加工模块后置处理导出车外圆及退刀槽的加工程序,螺纹段为手工编程。)6N10T017N25S500M038N30G1Z1.5F2540.9N35G0X172.10N40G1X161.5F100.11N45Z-298.512N50X165.13N55X165.109Z-298.50414N60X165.218Z-298.51615N65X165.326Z-298.53616N70X165.432Z-298.56417N75X165.536Z-298.59918N80X165.636Z-298.64219N85X165.734Z-298.69220N90X165.827Z-298.74921N95X165.916Z-298.81322N100X166.001Z-298.88323N105X166.08Z-298.95924N110X166.153Z-299.0425N115X166.22Z-299.12726N120X166.28Z-299.21827N125X166.334Z-299.31428N130X166.38Z-299.41329N135X166.419Z-299.51530N140X166.451Z-299.6231N145X166.475Z-299.72732N150X166.491Z-299.83533N155X166.499Z-299.94434N160X166.5Z-300.35N165X172.36N170G0Z1.537N175G1X156.9F100.38N180Z-248.539N185X160.40N190X160.109Z-248.50441N195X160.218Z-248.51642N200X160.326Z-248.53643N205X160.432Z-248.56444N210X160.536Z-248.59945N215X160.636Z-248.64246N220X160.734Z-248.69247N225X160.827Z-248.74948N230X160.916Z-248.81349N235X161.001Z-248.88350N240X161.08Z-248.95951N245X161.153Z-249.0452N250X161.22Z-249.12753N255X161.28Z-249.21854N260X161.334Z-249.31455N265X161.38Z-249.41356N270X161.419Z-249.51557N275X161.451Z-249.6258N280X161.475Z-249.72759N285X161.491Z-249.83560N290X161.499Z-249.94461N295X161.5Z-250.62N300X167.63N305G0Z1.564N310G1X152.3F100.65N315Z-248.566N320X162.467N325G0Z1.568N330G1X147.7F100.69N335Z-248.570N340X157.871N345G0Z1.572N350G1X143.1F100.73N355Z-248.574N360X153.275N365G0Z1.576N370G1X138.5F100.77N375Z-248.578N380X148.679N385G0Z1.580N390G1X133.9F100.81N395Z-248.582N400X144.83N405G0Z1.584N410G1X129.3F100.85N415Z-248.586N420X139.487N425G0Z1.588N430G1X124.7F100.89N435Z-248.590N440X134.891N445G0Z1.592N450G1X120.1F100.93N455Z-248.594N460X130.295N465G0Z1.596N470G1X115.5F100.97N475Z-248.598N480X125.699N485G0Z1.5100N490G1X110.5F100.101N495Z-199.379102N500X115.061Z-203.939103N505X115.135Z-204.02104N510X115.204Z-204.105105N515X115.266Z-204.195106N520X115.321Z-204.29107N525X115.369Z-204.388108N530X115.41Z-204.49109N535X115.444Z-204.594110N540X115.47Z-204.7111N545X115.488Z-204.808112N550X115.498Z-204.917113N555X115.5Z-205.114N560X121.115N565G0Z1.5116N570G1X105.5F100.117N575Z-198.5118N580X109.119N585X109.109Z-198.504120N590X109...