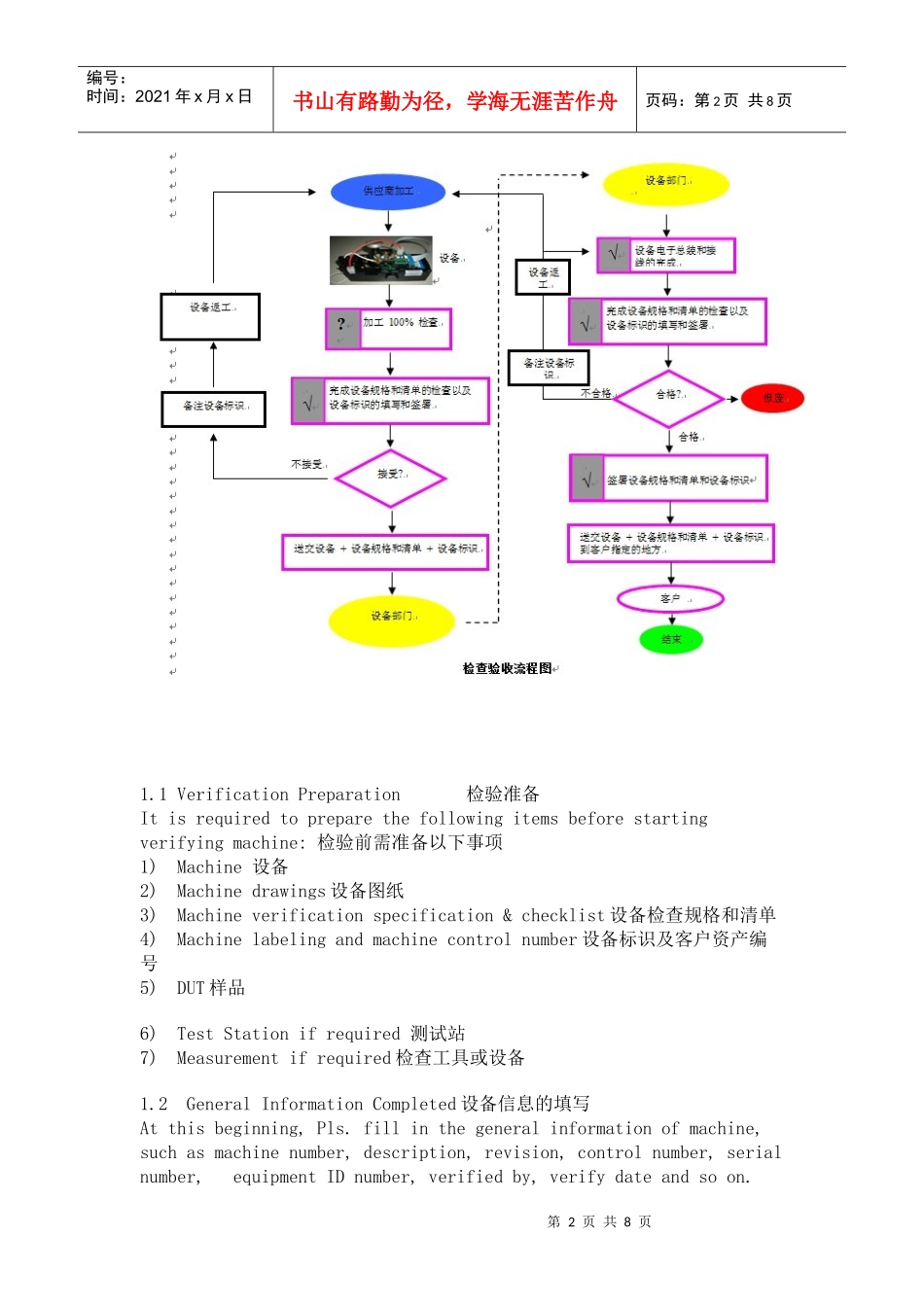

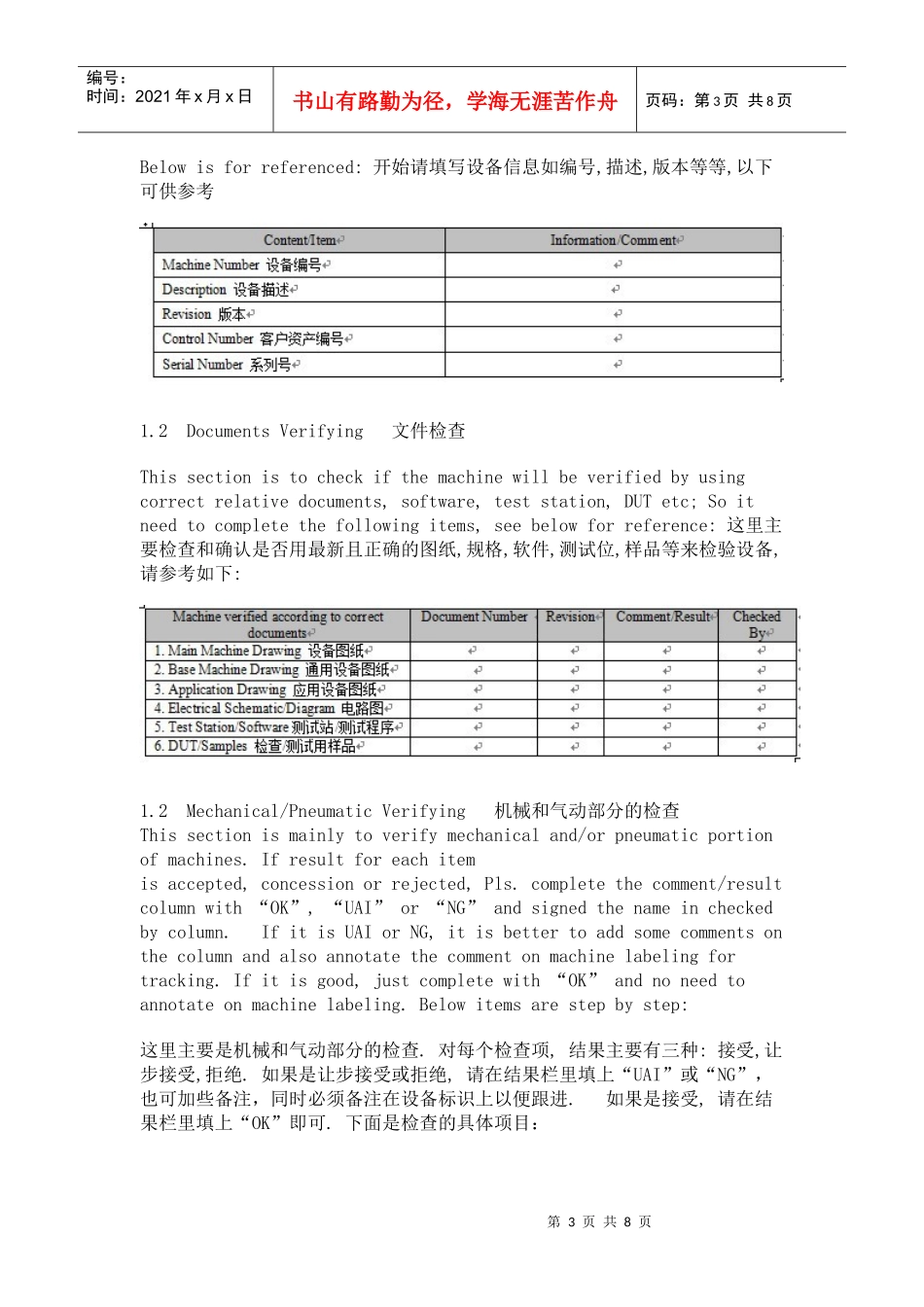

第1页共8页编号:时间:2021年x月x日书山有路勤为径,学海无涯苦作舟页码:第1页共8页设备验收流程及设备检验规格书以下为设备验收流程,仅供参考:1.0Machinequalificationactivitiesdescription设备验收执行过程描述Afterreceivingmachines,itwillspend1weektoverifymachinefunctionandreliabilitybeforesendittouser.Belowdescribesindetailshowtoverifymachinestepbystepuntilmachinedeliverytositeaccordingtotheflowchart.收到设备后,需要1周时间验证设备的功能和可靠性。以下定义设备检验步骤。QualificationFlowchart检查验收流程图:第2页共8页第1页共8页编号:时间:2021年x月x日书山有路勤为径,学海无涯苦作舟页码:第2页共8页1.1VerificationPreparation检验准备Itisrequiredtopreparethefollowingitemsbeforestartingverifyingmachine:检验前需准备以下事项1)Machine设备2)Machinedrawings设备图纸3)Machineverificationspecification&checklist设备检查规格和清单4)Machinelabelingandmachinecontrolnumber设备标识及客户资产编号5)DUT样品6)TestStationifrequired测试站7)Measurementifrequired检查工具或设备1.2GeneralInformationCompleted设备信息的填写Atthisbeginning,Pls.fillinthegeneralinformationofmachine,suchasmachinenumber,description,revision,controlnumber,serialnumber,equipmentIDnumber,verifiedby,verifydateandsoon.第3页共8页第2页共8页编号:时间:2021年x月x日书山有路勤为径,学海无涯苦作舟页码:第3页共8页Belowisforreferenced:开始请填写设备信息如编号,描述,版本等等,以下可供参考1.2DocumentsVerifying文件检查Thissectionistocheckifthemachinewillbeverifiedbyusingcorrectrelativedocuments,software,teststation,DUTetc;Soitneedtocompletethefollowingitems,seebelowforreference:这里主要检查和确认是否用最新且正确的图纸,规格,软件,测试位,样品等来检验设备,请参考如下:1.2Mechanical/PneumaticVerifying机械和气动部分的检查Thissectionismainlytoverifymechanicaland/orpneumaticportionofmachines.Ifresultforeachitemisaccepted,concessionorrejected,Pls.completethecomment/resultcolumnwith“OK”,“UAI”or“NG”andsignedthenameincheckedbycolumn.IfitisUAIorNG,itisbettertoaddsomecommentsonthecolumnandalsoannotatethecommentonmachinelabelingfortracking.Ifitisgood,justcompletewith“OK”andnoneedtoannotateonmachinelabeling.Belowitemsarestepbystep:这里主要是机械和气动部分的检查.对每个检查项,结果主要有三种:接受,让步接受,拒绝.如果是让步接受或拒绝,请在结果栏里填上“UAI”或“NG”,也可加些备注,同时必须备注在设备标识上以便跟进.如果是接受,请在结果栏里填上“OK”即可.下面是检查的具体项目:第4页共8页第3页共8页编号:时间:2021年x月x日书山有路勤为径,学海无涯苦作舟页码:第4页共8页1)Verifyrawmaterialsformanufacturingpartsarecorrectatdocumentedtype,Common&ESDMaterial检查机械加工件的原材料是否正确(非ESD材料)检查要求防静电的零件材料是否正确(ESD材料)2)Verifysurfacetreatmentformanufacturingpartiscorrectatdocumentedtypeandnoanyscratch/damage/brokenonsurfaceandnoanysharpedgeorburrs.检查机械加工件表面(颜色,处理工艺是否正确,外观有否擦伤痕迹/锐边/尖角等)3)Verifyallpartsaremanufacturedaccordingtocorrectdrawing,especiallycriticaldimensionmustbeverifiedinspecandenclosedwhendelivery.确保机械零件按图加工,要求提供符合要求的关键尺寸表4)Verifymanufacturingpartsareassembledinproperfashionandnomissing检查机械加工部件的装配是否正确及完整,有没有装反,装错或遗漏5)Verifyallfasteningparts(screw,washer,nut,bolt,spacer,circlip)areassembledcorrectlyandnomissingandsecurelyatdocumentedtorque检查紧固件(螺丝螺母卡簧等)是否安装正确,完整及可靠6)Verifycriticalcomponents(cylinder,bearings,linear,etc)isassembledcorrectly&can...