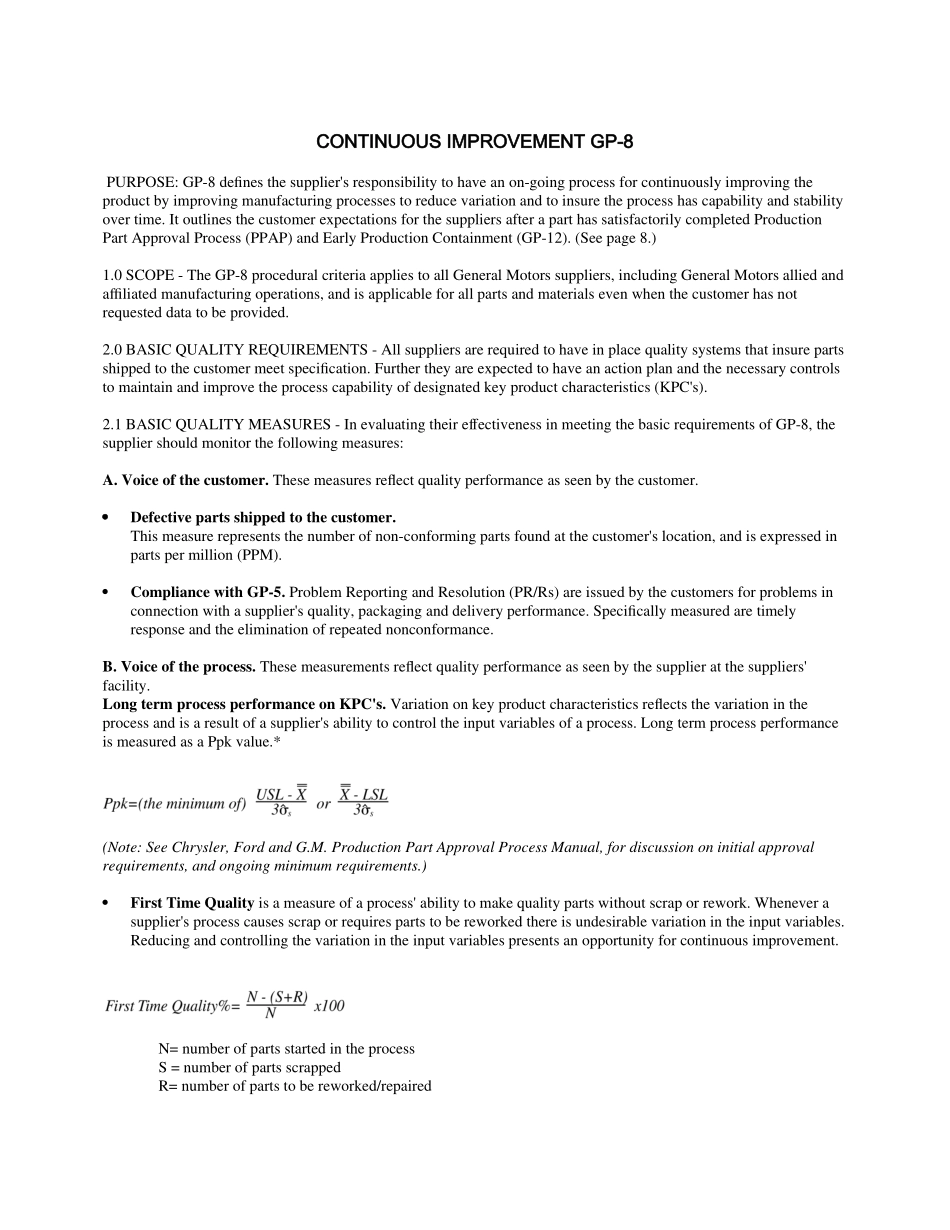

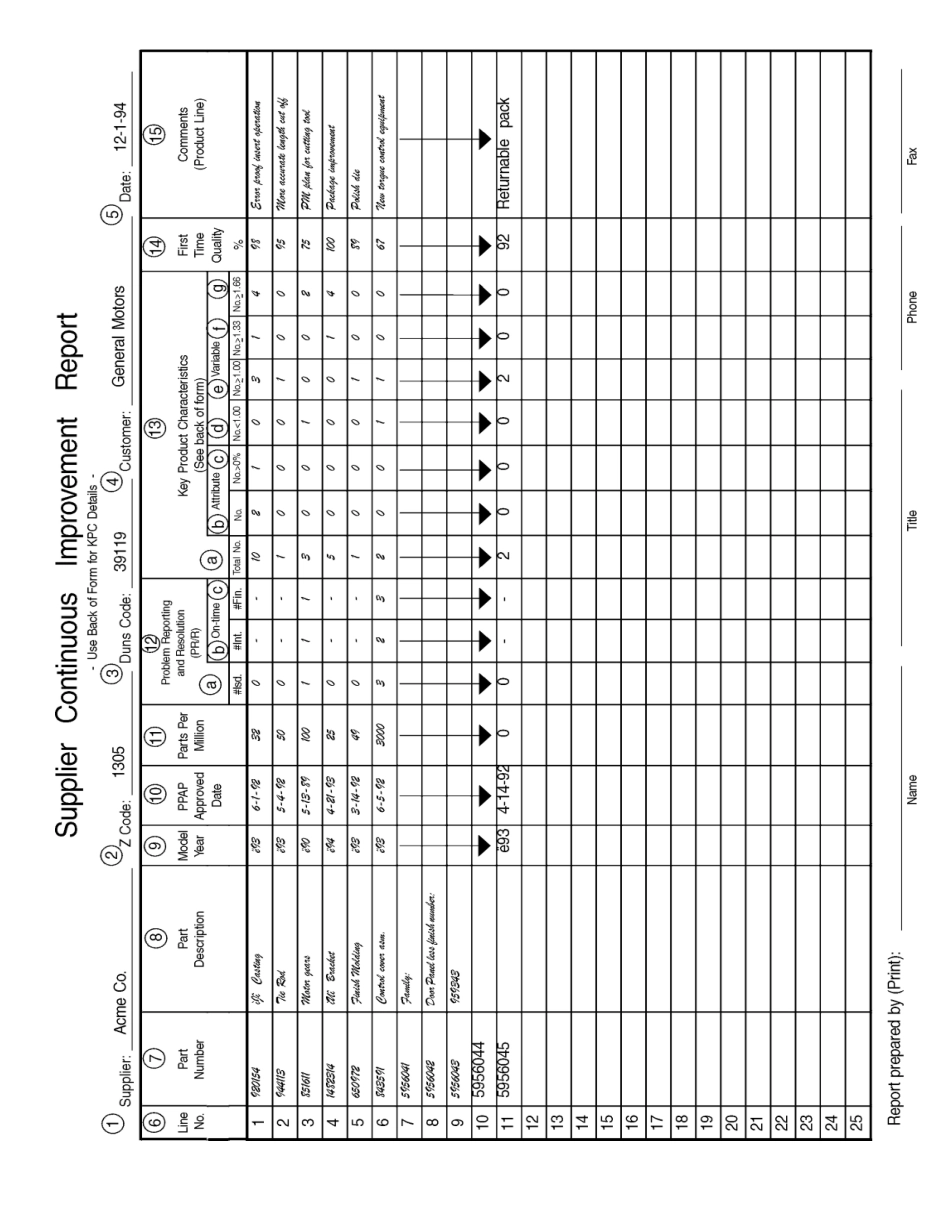

CONTINUOUSIMPROVEMENTGP-8PURPOSE:GP-8definesthesupplier'sresponsibilitytohaveanon-goingprocessforcontinuouslyimprovingtheproductbyimprovingmanufacturingprocessestoreducevariationandtoinsuretheprocesshascapabilityandstabilityovertime.ItoutlinesthecustomerexpectationsforthesuppliersafteraparthassatisfactorilycompletedProductionPartApprovalProcess(PPAP)andEarlyProductionContainment(GP-12).(Seepage8.)1.0SCOPE-TheGP-8proceduralcriteriaappliestoallGeneralMotorssuppliers,includingGeneralMotorsalliedandaffiliatedmanufacturingoperations,andisapplicableforallpartsandmaterialsevenwhenthecustomerhasnotrequesteddatatobeprovided.2.0BASICQUALITYREQUIREMENTS-Allsuppliersarerequiredtohaveinplacequalitysystemsthatinsurepartsshippedtothecustomermeetspecification.Furthertheyareexpectedtohaveanactionplanandthenecessarycontrolstomaintainandimprovetheprocesscapabilityofdesignatedkeyproductcharacteristics(KPC's).2.1BASICQUALITYMEASURES-InevaluatingtheireffectivenessinmeetingthebasicrequirementsofGP-8,thesuppliershouldmonitorthefollowingmeasures:A.Voiceofthecustomer.Thesemeasuresreflectqualityperformanceasseenbythecustomer.Defectivepartsshippedtothecustomer.Thismeasurerepresentsthenumberofnon-conformingpartsfoundatthecustomer'slocation,andisexpressedinpartspermillion(PPM).CompliancewithGP-5.ProblemReportingandResolution(PR/Rs)areissuedbythecustomersforproblemsinconnectionwithasupplier'squality,packaginganddeliveryperformance.Specificallymeasuredaretimelyresponseandtheeliminationofrepeatednonconformance.B.Voiceoftheprocess.Thesemeasurementsreflectqualityperformanceasseenbythesupplieratthesuppliers'facility.LongtermprocessperformanceonKPC's.Variationonkeyproductcharacteristicsreflectsthevariationintheprocessandisaresultofasupplier'sabilitytocontroltheinputvariablesofaprocess.LongtermprocessperformanceismeasuredasaPpkvalue.*(Note:SeeChrysler,FordandG.M.ProductionPartApprovalProcessManual,fordiscussiononinitialapprovalrequirements,andongoingminimumrequirements.)FirstTimeQualityisameasureofaprocess'abilitytomakequalitypartswithoutscraporrework.Wheneverasupplier'sprocesscausesscraporrequirespartstobereworkedthereisundesirablevariationintheinputvariables.Reducingandcontrollingthevariationintheinputvariablespresentsanopportunityforcontinuousimprovement.N=numberofpartsstartedintheprocessS=numberofpartsscrappedR=numberofpartstobereworked/repairedCONTINUOUSIMPROVEMENTGP-83.0CUSTOMEREXPECTATIONSFORTHESUPPLIERS'CONTINUOUSIMPROVEMENTPROCESS--UponsuccessfullymeetingthecriteriaforexitingEarlyProductionContainment(GP-12),thesupplierisresponsibletohaveaqualitysystemthatcontinuestoproducematerialoverthelongtermthatmeetsspecifications.Allsuppliersareexpectedtomeasuretheirqualityperformanceandworkforcontinuousimprovementonallparts.Theprocessistohavethesupportandinvolvementofthesuppliers'topleadership.3.1GOALOFCONTINUOUSIMPROVEMENT--Thegoalofthecontinuousimprovementprocessistoreducevariationinthemanufacturingprocessandtoimprovethequalityofthepartsproduced.*SeetheChrysler,Ford,GMFundamentalSPCReferenceManualpages80-81forfurtherinformation.3.2IDENTIFYINGPROCESSESFORCONTINUOUSIMPROVEMENT--Suppliersshouldconcentratetheireffortsonreductionofprocessvariationbylisteningtothevoiceoftheprocessandthevoiceofthecustomer.Inanalyzingfirsttimequalitydata,thepartoftheprocessthatcreatesscraporwhenpartsrequirereworkisthepointin...