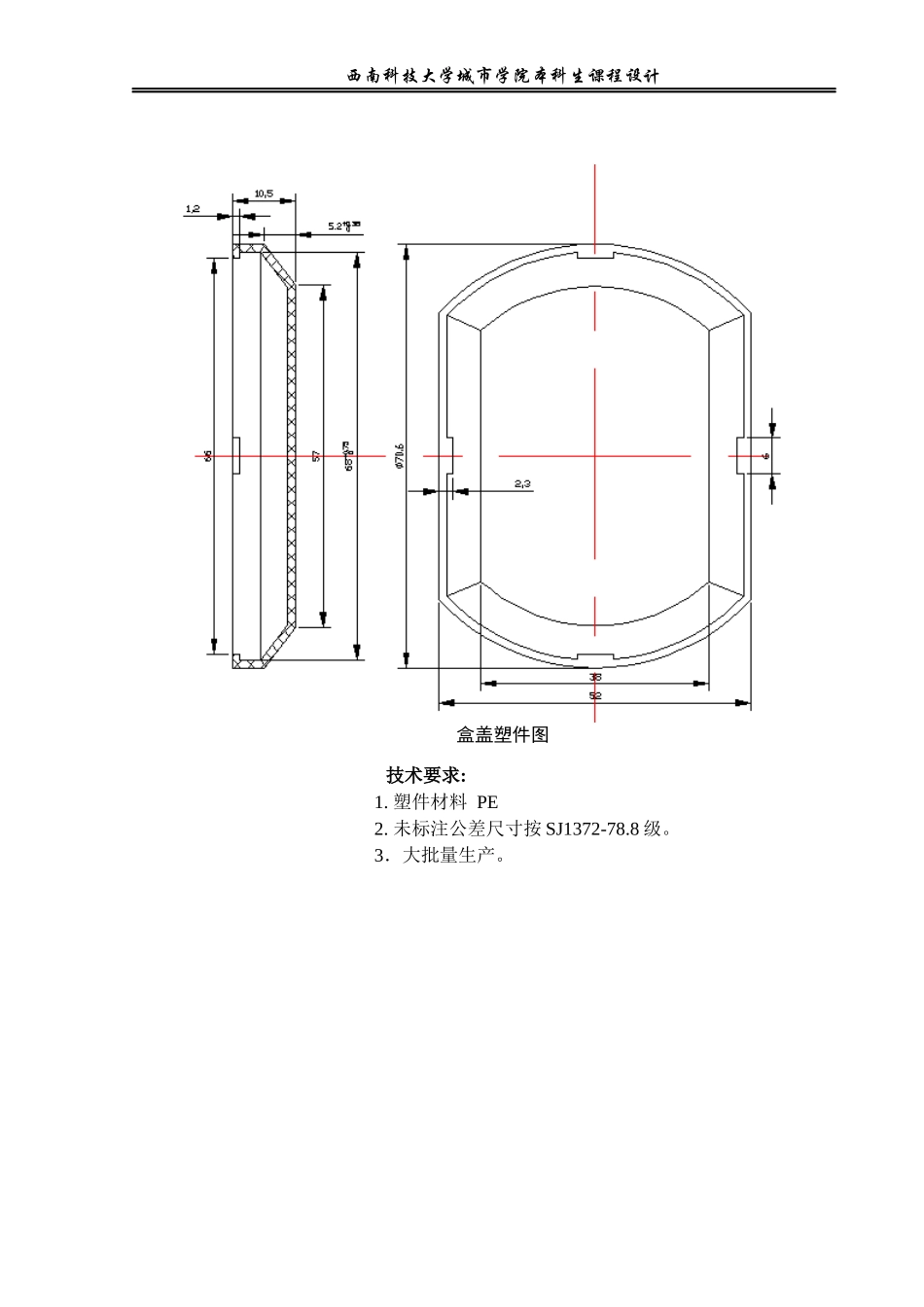

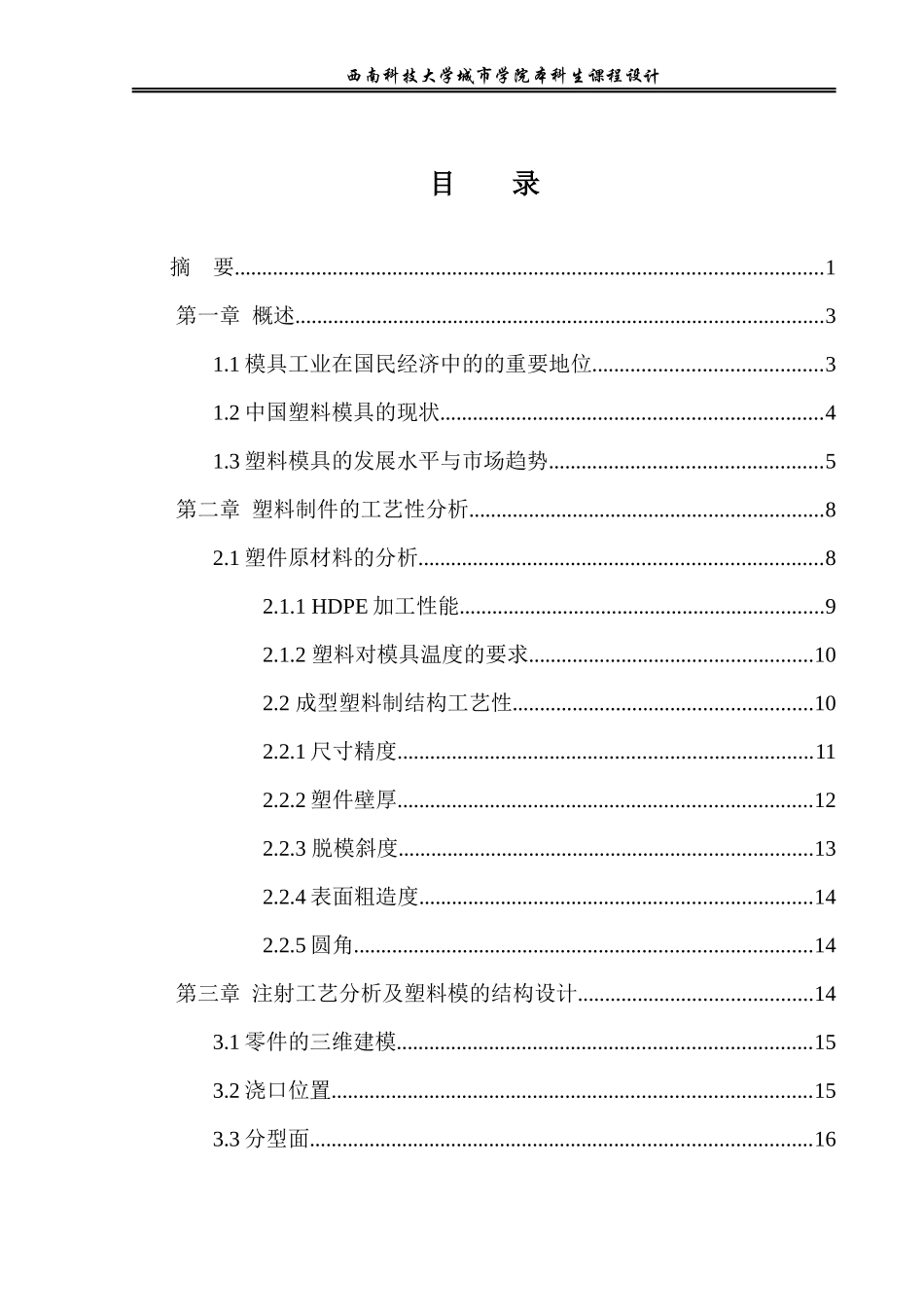

分数课程设计论文(设计)论文题目:注塑盒盖模具设计指导教师:系别:机电工程系专业班级:机械设计制造及其自动化1101姓名:日期:2014年6月西南科技大学城市学院本科生课程设计盒盖塑件图技术要求:1.塑件材料PE2.未标注公差尺寸按SJ1372-78.8级。3.大批量生产。西南科技大学城市学院本科生课程设计目录摘要............................................................................................................1第一章概述.................................................................................................31.1模具工业在国民经济中的的重要地位..........................................31.2中国塑料模具的现状......................................................................41.3塑料模具的发展水平与市场趋势..................................................5第二章塑料制件的工艺性分析.................................................................82.1塑件原材料的分析..........................................................................82.1.1HDPE加工性能...................................................................92.1.2塑料对模具温度的要求....................................................102.2成型塑料制结构工艺性.......................................................102.2.1尺寸精度............................................................................112.2.2塑件壁厚............................................................................122.2.3脱模斜度............................................................................132.2.4表面粗造度........................................................................142.2.5圆角....................................................................................14第三章注射工艺分析及塑料模的结构设计...........................................143.1零件的三维建模............................................................................153.2浇口位置........................................................................................153.3分型面............................................................................................16西南科技大学城市学院本科生课程设计3.4型腔的数目与布局........................................................................173.4.1模具型腔数目....................................................................173.5浇注方案的设计............................................................................183.5.1确定浇注系统的原则........................................................183.5.2浇口形式的选择................................................................193.5.3主流道形状与尺寸............................................................203.5.4点浇口尺寸的确定............................................................213.5.5点浇口剪切速率的校核....................................................223.5.6浇注系统方案....................................................................223.6型腔的强度校核............................................................................233.6.1整体式矩形型腔侧壁和底板厚度的计算........................233.6.2整体式圆形型腔侧壁和底板厚度的计算........................243.7脱模机构的设计............................................................................273.8型芯型腔尺寸的计算....................................................................283.9脱模机构尺寸计算........................................................................