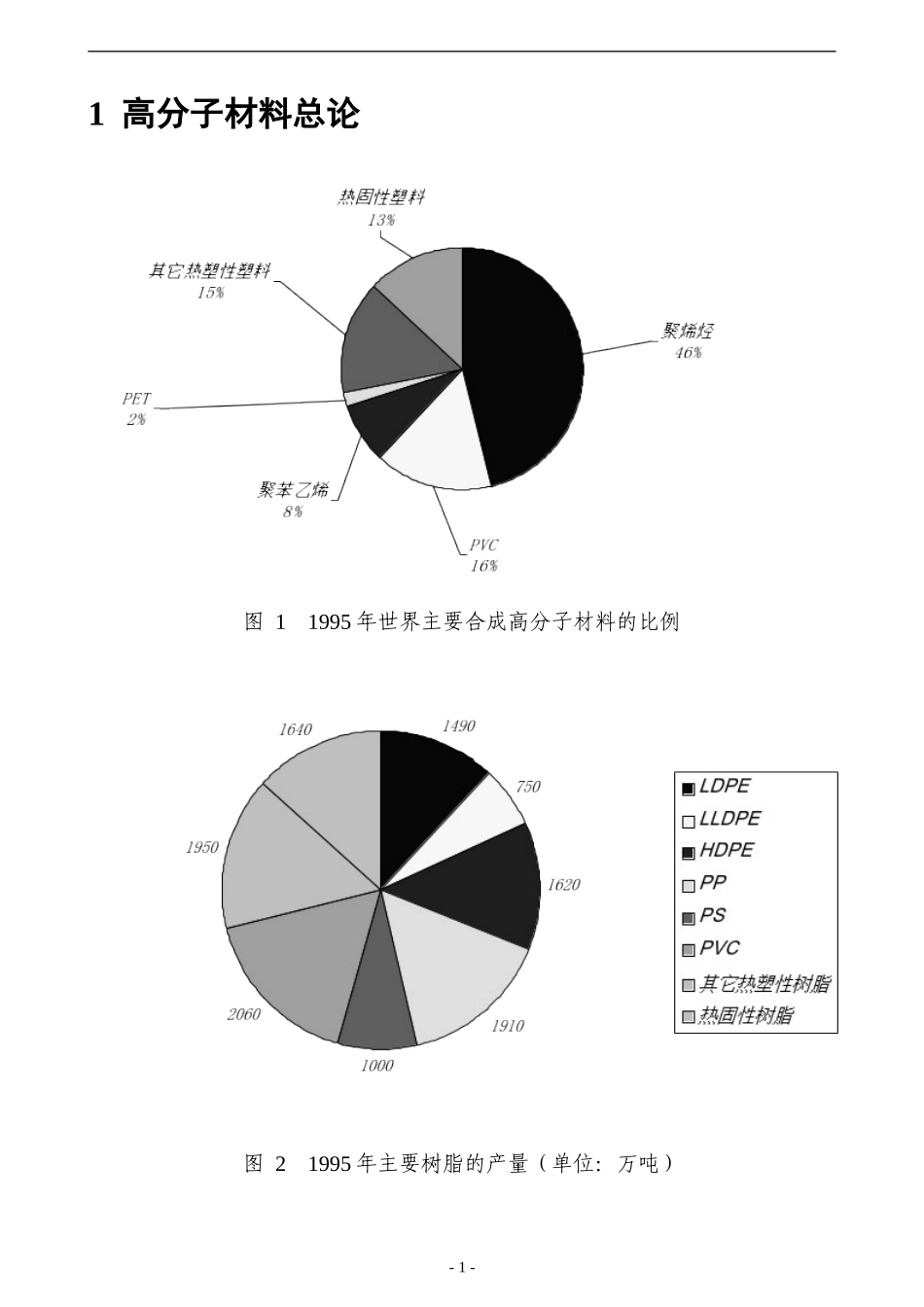

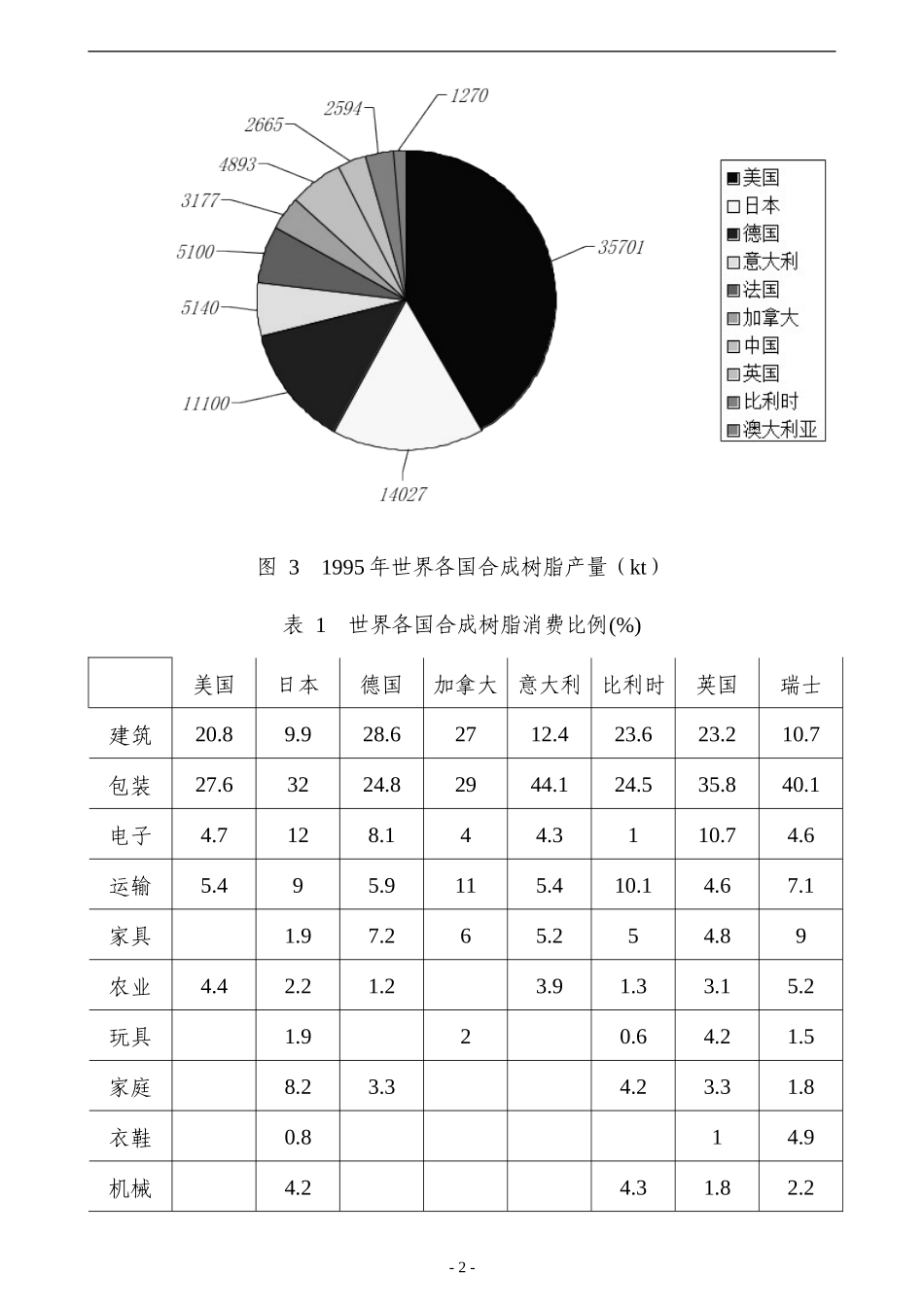

1高分子材料总论图11995年世界主要合成高分子材料的比例图21995年主要树脂的产量(单位:万吨)-1-图31995年世界各国合成树脂产量(kt)表1世界各国合成树脂消费比例(%)美国日本德国加拿大意大利比利时英国瑞士建筑20.89.928.62712.423.623.210.7包装27.63224.82944.124.535.840.1电子4.7128.144.3110.74.6运输5.495.9115.410.14.67.1家具1.97.265.254.89农业4.42.21.23.91.33.15.2玩具1.920.64.21.5家庭8.23.34.23.31.8衣鞋0.814.9机械4.24.31.82.2-2-医疗0.122.52其它37.117.820.9924.7222.512.9-3-2通用塑料2.1主要品种PP(等规度):无规(APP),均聚(IPP),嵌段共聚(C2,BPP)表2不同流动性APP和BPP的性能聚丙烯品种无规共聚PP嵌段共聚PPMFR0.30.51.04.08.00.30.51.04.08.0脆化温度,℃-5-20310-25-25-20-8-3Charpy冲击强度85433353520107混浊度,%40424555657070708085软化点,℃140表3均聚PP与共聚PP性能对比PP品种均聚PP嵌段共聚PP密度,g/cm30.9030.90拉伸屈服强度,MPa37.029.0弯曲模量,MPa19001350洛氏硬度,R10240Izod缺口冲击强度,J/m48500热变形温度(1.82MPa),℃5862脆性温度,℃-5-30-1-表4意大利Molplen均聚PP的性能D50GQ30GS30GT30GC30GX30GF30SV30GMFR0.30.71.83681216注塑流动螺旋试验320380450510600670750800FM14001450145015001600160017001750TY3334353637373838EY1413121212121111Izodnotched23C200100655045383538洛氏硬度8490909094949798VST/A/50152152153153154154155155HDT/B9292949596959798150C老化1500360360360360360360360表5意大利Molplen共聚PP的性能EP-D60REP-Q30MEP-S30REP-T30REP-C30REP-F30REP-H31RAMFR0.30.81.53.571340注塑流动螺旋试验330420450550680800>800FM1100130012001300140014501450TY27302729292929-2-EY15151312121211Izodnotched>500300350150957570洛氏硬度77828081848890VST/A/50150150150150150150150HDT/B90908588889090-3-表6QK004000主要性能指标编号1112212231324142弯曲模量ISO1781000-15001500-20002000-25002500-3000Charpy冲击强度ISO179/1eUat23℃n.b.n.b.at–30℃5030Charpy缺口冲击强度ISO179/1eAat23℃40203025208105at–30℃8444363密度ISO11831.00±0.11.10±0.11.15±0.11.20±0.1屈服强度ISO527-215171921VST/A/50ISO308115120120125125130130135VST/B/504545455050555560HDT/AISO75-24550485352575560HDT/B70857590809585100球压痕硬度ISO2039-13045405050556060-4-表7大众汽车公司TL52283PP/talc共混物的性能指标无尾标规格A规格B用途仪表板侧护板镶嵌条填料用量23±329±326±3比重1.09±0.011.13±0.011.10±0.01Tm,℃min158158158布氏硬度,MPa38-4550-5643-48拉伸强度,MPamin13.01815断裂伸长率,%min202020缺口冲击韧性不断裂,允许部分断裂不断裂,允许部分断裂乃至铰链式断裂不断裂,允许部分断裂弯曲强度,MPa-40±1℃22-8029-9023-75-23±2℃>22>29>2380±1℃>9>12>9-5-表8大众汽车公司汽车用保险杠材料(PP/橡胶)无尾标规格A规格B汽车类型GolfA2A3T4GolfA4填料用量10±2比重0.87-0.920.89-0.930.95-1.0布氏硬度,MPa28±450±528±4拉伸强度,MPamin12.01812断裂伸长率,%min10010020缺口冲击韧性不断裂不断裂,允许部分断裂弯曲强度,MPa-40±1℃18-6327-6218-70-23±2℃>18>27>1880±1℃>6>9>9耐热老化性(150℃)>200>200>200-6-表9Molplen橡胶增韧PPSP25/ASP150SP1041SP132SP151SP1114SP1120MFR43.5443.54.57.5密度0.9050.8920.8910.90.90.9230.928注塑流动螺旋试验540540505550540580570收缩率1.3-1.51.0-1.31.0-1.21.3-1.51.0-1.21.0-1.21.0-1.2弯曲模量950700750100075010501200屈服强度21161723191719断裂伸长率>400>400>400>400>400>400>400邵D62565262565762Izod缺口冲击强度23℃>5000℃400500>500120>500>500>500-20℃120300>50090350350120VST/A/50140116123142126133141VST/B/5053554365555055HDT/A76646675648083HDT/B46464449464851主要用作汽车保险杠、汽车侧护板及扰流板-7-PE(密度,分子量):HDPE,LLDPE,LDPE,MDPE,UHMWHDPE(大于150万);表10PE的典型...