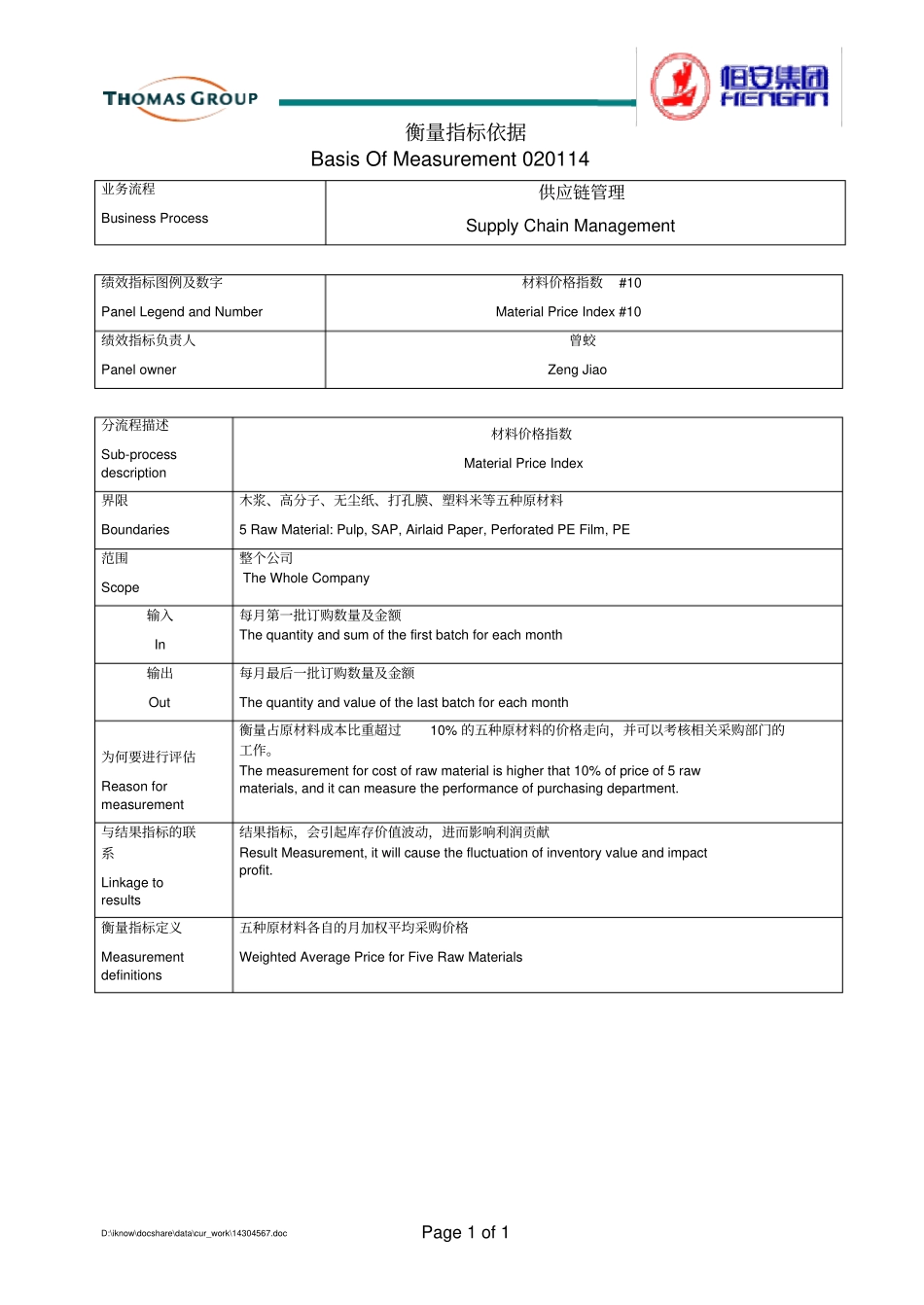

衡量指标依据BasisOfMeasurement020114D:\iknow\docshare\data\cur_work\14304567.docPage1of1业务流程BusinessProcess供应链管理SupplyChainManagement绩效指标图例及数字PanelLegendandNumber材料价格指数#10MaterialPriceIndex#10绩效指标负责人Panelowner曾蛟ZengJiao分流程描述Sub-processdescription材料价格指数MaterialPriceIndex界限Boundaries木浆、高分子、无尘纸、打孔膜、塑料米等五种原材料5RawMaterial:Pulp,SAP,AirlaidPaper,PerforatedPEFilm,PE范围Scope整个公司TheWholeCompany输入In每月第一批订购数量及金额Thequantityandsumofthefirstbatchforeachmonth输出Out每月最后一批订购数量及金额Thequantityandvalueofthelastbatchforeachmonth为何要进行评估Reasonformeasurement衡量占原材料成本比重超过10%的五种原材料的价格走向,并可以考核相关采购部门的工作。Themeasurementforcostofrawmaterialishigherthat10%ofpriceof5rawmaterials,anditcanmeasuretheperformanceofpurchasingdepartment.与结果指标的联系Linkagetoresults结果指标,会引起库存价值波动,进而影响利润贡献ResultMeasurement,itwillcausethefluctuationofinventoryvalueandimpactprofit.衡量指标定义Measurementdefinitions五种原材料各自的月加权平均采购价格WeightedAveragePriceforFiveRawMaterials衡量指标依据BasisOfMeasurement020114D:\iknow\docshare\data\cur_work\14304567.docPage2of1衡量指标计算公式及图表生成Measurementcalculation(formula)andGraphlayout∑(当月从某供应商处订购的数量/当月该原材料订购总数量X100%)乘以当月从该供应商订购的平均价格∑(Thequantityorderpermonthpersupplier/TotalRawMaterialquantityorderpermonthX100%)Xtheaveragepricepermonthpersupplier说明:本衡量指标依据包含的五种原材料均适用上述公式。Note:ThisBFMconsistsof5RawMaterialswhichissuitablefortheabove-mentionedformula数据收集的频率Frequencyofdatacollection每月一次,在下月的1~5日收集Onceforeachmonth,1-5ofthefollowingmonth数据来源Datasource采购供应链月报MonthlyReportofPurchasingandSupplyChain基线Baseline105,890$105,890基线设立的依据Basisforbaseline2001年1月到11月的平均值JanuarytoNovember2001average能力可达绩效Entitlement93,183$93,183可达绩效设立依据BasisforEntitlement同基线相比,目标状况有12%的提高(确立于架构中)Entitlementrepresentsa12%improvement(whichwasestablishedinthearchitecture)绩效考评图整合流程Cockpitchartconsolidationprocess每月由负责人收集数据,交衡量专员DatawillbecollectedbyPanelOwnerandsubmittedtoMeasurementSpecialistmonthly.评估专员(张碧玲)MeasurementSpecialist(ZhangBiLing)签名:Sign.日期:Date:流程顾问(泰维多)ProcessResultant(Victor)签名:Sign.日期:Date:跨功能小组领导(王向阳)CFTLeader(WangXiangYang)签名Sign.日期:Date:评估负责人(许大座)MeasurementOwner(XuDaZuo)签名Sign.日期:Date: