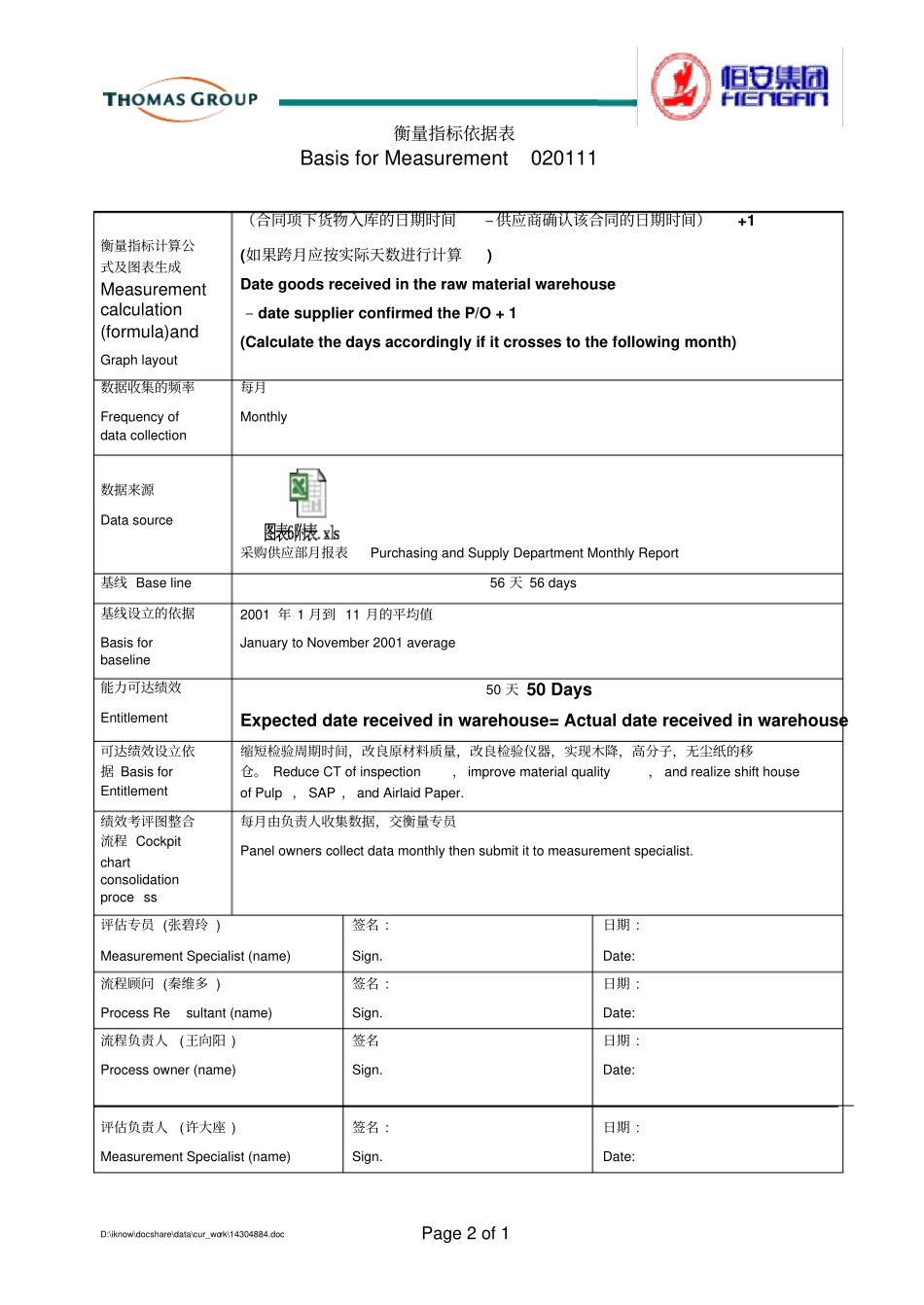

衡量指标依据表BasisforMeasurement020111D:\iknow\docshare\data\cur_work\14304884.docPage1of1业务流程BusinessProcess供应链管理SupplyChainManagement绩效指标图例及数字PanelLegendandNumber供应商订货到货时间#6SupplierLeadTime#6绩效指标负责人Panelowner曾蛟ZengJiao分流程描述Sub-processdescription供应商订货到货时间SupplierLeadTime界限Boundaries从供应商确认五种主要原材料-(木浆,塑料米,打孔膜,无尘纸,高分子)订单到该批货物入库SinceSupplierofthe5majorcommodities(Pulp,PE,PerforatedPEFilm,AirlaidPaper,SAP)confirmsthePurchaseOrdertillgoodsisdeliveredintotherawmaterialwarehouse.范围Scope整个公司TheWholeCompany输入In供应商确认合同ContractConfirmationofSupplier输出Out原材料入库完毕RawMaterialhasbeendeliveredintowarehouse为何要进行评估Reasonformeasurement缩短供应商订货到货周期时间ReduceSupplierLeadTime与结果指标的联系Linkagetoresults通过缩短和控制供应商的订货到货周期时间,减少现有库存天数,降低库存价值Bycontrollingandreducingtheleadtimetoreducetheinventorydaysonhandandinventoryvalue衡量指标定义Measurementdefinitions从供应商确认合同到该合同项下的货物质检合格入库SinceSupplierconfirmsthePurchasingOrdertillgoodsindicatedinthecontractisdeliveredintowarehouseafterqualityinspection衡量指标依据表BasisforMeasurement020111D:\iknow\docshare\data\cur_work\14304884.docPage2of1衡量指标计算公式及图表生成Measurementcalculation(formula)andGraphlayout(合同项下货物入库的日期时间–供应商确认该合同的日期时间)+1(如果跨月应按实际天数进行计算)Dategoodsreceivedintherawmaterialwarehouse–datesupplierconfirmedtheP/O+1(Calculatethedaysaccordinglyifitcrossestothefollowingmonth)数据收集的频率Frequencyofdatacollection每月Monthly数据来源Datasource采购供应部月报表PurchasingandSupplyDepartmentMonthlyReport基线Baseline56天56days基线设立的依据Basisforbaseline2001年1月到11月的平均值JanuarytoNovember2001average能力可达绩效Entitlement50天50DaysExpecteddatereceivedinwarehouse=Actualdatereceivedinwarehouse可达绩效设立依据BasisforEntitlement缩短检验周期时间,改良原材料质量,改良检验仪器,实现木降,高分子,无尘纸的移仓。ReduceCTofinspection,improvematerialquality,andrealizeshifthouseofPulp,SAP,andAirlaidPaper.绩效考评图整合流程Cockpitchartconsolidationprocess每月由负责人收集数据,交衡量专员Panelownerscollectdatamonthlythensubmitittomeasurementspecialist.评估专员(张碧玲)MeasurementSpecialist(name)签名:Sign.日期:Date:流程顾问(秦维多)ProcessResultant(name)签名:Sign.日期:Date:流程负责人(王向阳)Processowner(name)评估负责人(许大座)MeasurementSpecialist(name)签名Sign.签名:Sign.日期:Date:日期:Date: