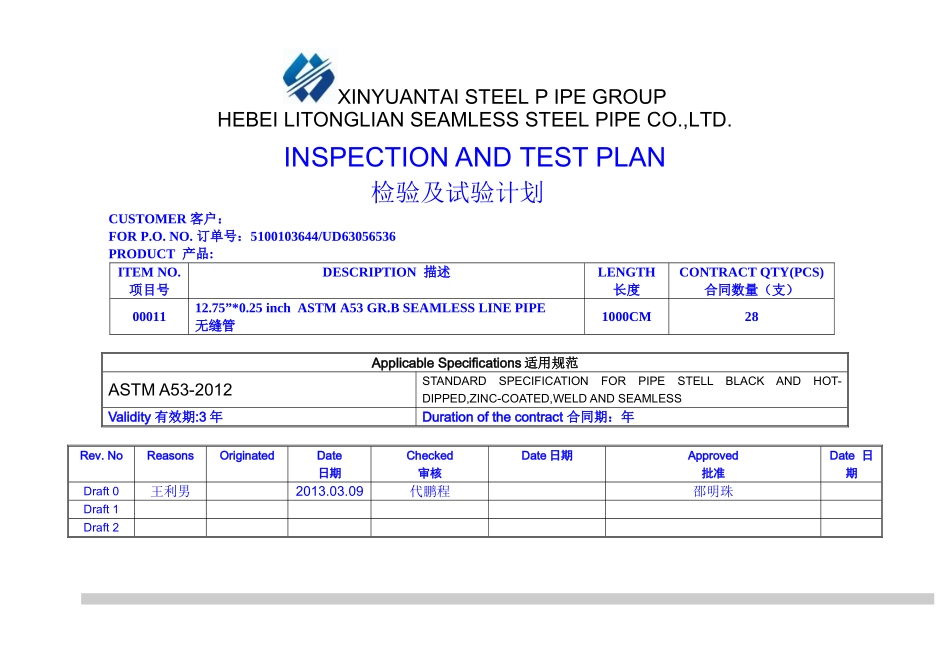

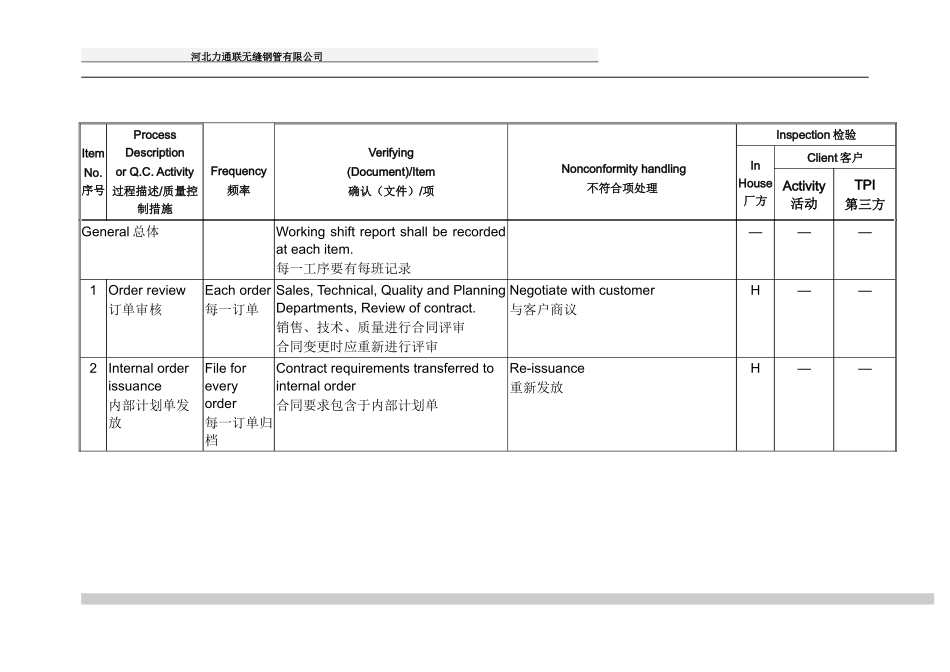

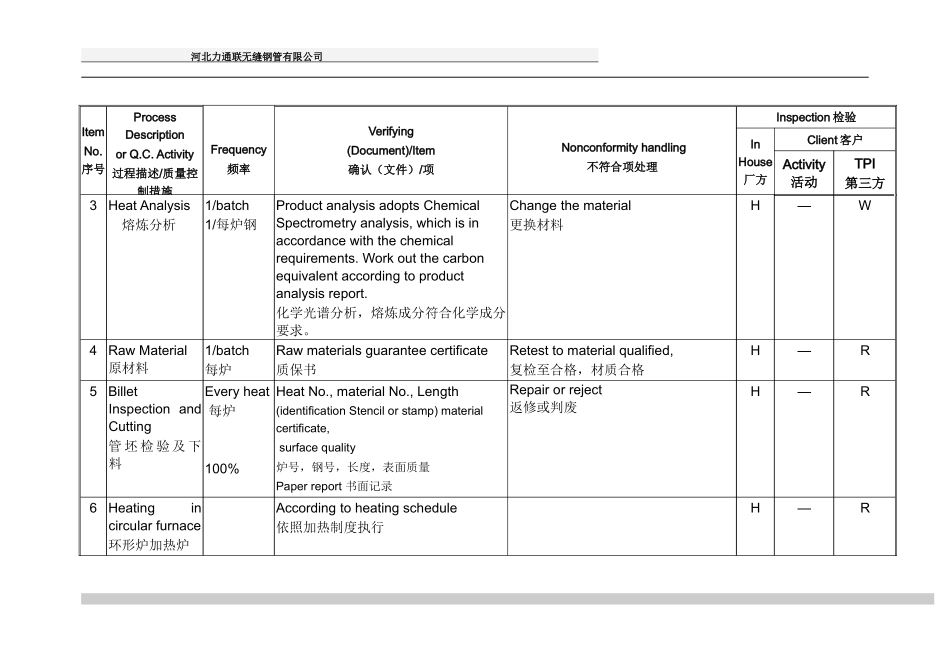

XINYUANTAISTEELPIPEGROUPHEBEILITONGLIANSEAMLESSSTEELPIPECO.,LTD.INSPECTIONANDTESTPLAN检验及试验计划CUSTOMER客户:FORP.O.NO.订单号:5100103644/UD63056536PRODUCT产品:ITEMNO.项目号DESCRIPTION描述LENGTH长度CONTRACTQTY(PCS)合同数量(支)0001112.75”*0.25inchASTMA53GR.BSEAMLESSLINEPIPE无缝管1000CM28ApplicableSpecifications适用规范ASTMA53-2012STANDARDSPECIFICATIONFORPIPESTELLBLACKANDHOT-DIPPED,ZINC-COATED,WELDANDSEAMLESSValidity有效期:3年Durationofthecontract合同期:年Rev.NoReasonsOriginatedDate日期Checked审核Date日期Approved批准Date日期Draft0王利男2013.03.09代鹏程邵明珠Draft1Draft2河北力通联无缝钢管有限公司ItemNo.序号ProcessDescriptionorQ.C.Activity过程描述/质量控制措施Frequency频率Verifying(Document)/Item确认(文件)/项Nonconformityhandling不符合项处理Inspection检验InHouse厂方Client客户Activity活动TPI第三方General总体Workingshiftreportshallberecordedateachitem.每一工序要有每班记录———1Orderreview订单审核Eachorder每一订单Sales,Technical,QualityandPlanningDepartments,Reviewofcontract.销售、技术、质量进行合同评审合同变更时应重新进行评审Negotiatewithcustomer与客户商议H——2Internalorderissuance内部计划单发放Fileforeveryorder每一订单归档Contractrequirementstransferredtointernalorder合同要求包含于内部计划单Re-issuance重新发放H——河北力通联无缝钢管有限公司ItemNo.序号ProcessDescriptionorQ.C.Activity过程描述/质量控制措施Frequency频率Verifying(Document)/Item确认(文件)/项Nonconformityhandling不符合项处理Inspection检验InHouse厂方Client客户Activity活动TPI第三方3HeatAnalysis熔炼分析1/batch1/每炉钢ProductanalysisadoptsChemicalSpectrometryanalysis,whichisinaccordancewiththechemicalrequirements.Workoutthecarbonequivalentaccordingtoproductanalysisreport.化学光谱分析,熔炼成分符合化学成分要求。Changethematerial更换材料H—W4RawMaterial原材料1/batch每炉Rawmaterialsguaranteecertificate质保书Retesttomaterialqualified,复检至合格,材质合格H—R5BilletInspectionandCutting管坯检验及下料Everyheat每炉100%HeatNo.,materialNo.,Length(identificationStencilorstamp)materialcertificate,surfacequality炉号,钢号,长度,表面质量Paperreport书面记录Repairorreject返修或判废H—R6Heatingincircularfurnace环形炉加热炉Accordingtoheatingschedule依照加热制度执行H—R河北力通联无缝钢管有限公司ItemNo.序号ProcessDescriptionorQ.C.Activity过程描述/质量控制措施Frequency频率Verifying(Document)/Item确认(文件)/项Nonconformityhandling不符合项处理Inspection检验InHouse厂方Client客户Activity活动TPI第三方7Piercing,hotrolling穿孔,轧制8hourspershift每班8小时Surfacecheckingofthemandrel检查芯棒的表面质量H—R8Slight-stretchreduction微张力减径Accordingtositeconditions根据现场情况ODandWTchecking检验外径及壁厚尺寸H—R9Samplingforpipebody管体取样2perlotof200pcs2/批(200支)MaketwospecimensforeachlotofsamplesandmarkfurnacebatchNo.onthem.(Sample,markandstampaccordingtoAPT5Lstandard.)每组试样做成两个试片并且在试样上用记号笔标明具体炉批号(做标记及做钢印,钢印做批号的后两位)Takenewsamples另取样H—W河北力通联无缝钢管有限公司ItemNo.序号ProcessDescriptionorQ.C.Activity过程描述/质量控制措施Frequency频率Verifying(Document)/Item确认(文件)/项Nonconformityhandling不符合项处理Inspection检验InHouse厂方Client客户Activity活动TPI第三方10ChemicalAnalysis产品化学分析2/heat2/炉ProductanalysisadoptsChemicalSpectrometryanalysis,whichisinaccordancewiththechemicalrequirements.产品分析采用化学光谱分析法;必须符合化学成分表的要求;Re-test,reject重测,判废H—W+R...