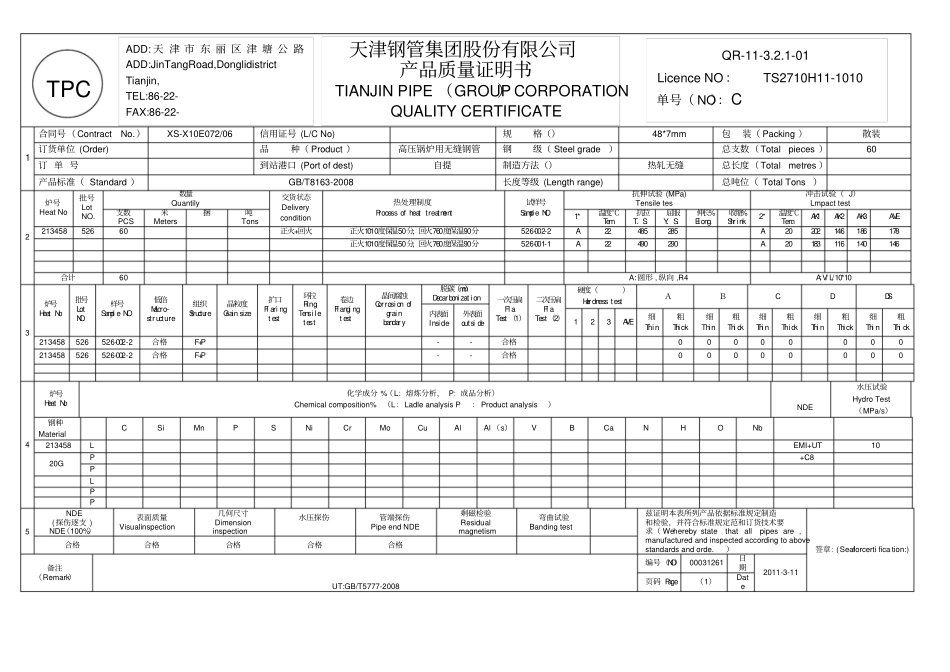

TPC1合同号( Contract No.)XS-X10E072/06信用证号 (L/C No)规格()48*7mm包装( Packing )散装订货单位 (Order)品种( Product )高压锅炉用无缝钢管钢级( Steel grade)总支数( Total pieces )60订 单 号到站港口 (Port of dest)自提制造方法()热轧无缝总长度( Total metres )产品标准( Standard )GB/T8163-2008长度等级 (Length range)总吨位( Total Tons)2炉号Heat No批号Lot NO.数量Quantily交货状态Deliverycondition热处理制度Process of heat treatment试样号Sample NO.抗伸试验 (MPa)Tensile tes冲击试验( J)Lmpact test支数PCS米Meters捆吨Tons1*温度℃Tem抗拉T.S.屈服Y.S.伸长%Elong.收缩%Shrink2*温度℃Tem.AK1AK2AK3AVE21345852660正火+回火正火1010度保温50分,回火760度保温90分526-002-2A22485285A20202146186178正火1010度保温50分,回火760度保温90分526-001-1A22490290A20183116140146合计60A:圆形 , 纵向 ,R4A:V/ L/10*103炉号Heat No批号LotNO.样号Sampl e NO.低倍Macro-structure组织Structure晶粒度Grain size扩口Fl ari ngt est环拉RingTensiletest卷边Flangi ngt est晶间腐蚀Corrosion ofgrainbandary脱碳(mm)Decarbonizat ion一次压扁FlaTest (1)二次压扁Fl aTest(2)硬度()Hardness testABCDDS内表面Inside外表面outsi de123AVE细Thin粗Thick细Thin粗Thi ck细Thin粗Thick细Thi n粗Thick细Thi n粗Thi ck213458526526-002-2合格F+P--合格00000000213458526526-002-2合格F+P--合格000000004炉号Heat No化学成分 %(L:熔炼分析, P:成品分析)Chemical composition%(L:Ladle analysis P: Product analysis)NDE水压试验Hydro Test(MPa/s)钢种MaterialCSiMnPSNiCrMoCuAlAl (s)VBCaNHONb213458LEMI+UT1020GP+C8PLPP5NDE(探伤逐支 )NDE(100%)表面质量Visualinspection几何尺寸Dimensioninspection水压探伤管端探伤Pipe end NDE剩磁检验Residualmagnetism弯曲试验Banding test兹证明本表所列产品依据标准规定制造和检验,并符合标准规定范和订货技术要求( We hereby state that all pipes are ,manufactured and inspected according to above standards and orde.)签章:(Sealforcerti fica tion:)合格合格合格合格合格备注(Remark)UT:GB/T5777-2008编号(NO)00031261日期2011-3-11页码 Page(1)DateADD: 天 津 市 东 丽 区 津 塘 公 路ADD:JinTangRoad,Donglidistrict Tianjin, TEL:86-22- FAX:86-22-天津钢管集团股份有限公司产品质量证明书TIANJIN PIPE (GROUP)CORPORATION QUALITY CERTIFICATE QR-11-3.2.1-01Licence NO : TS2710H11-1010单号( NO):C