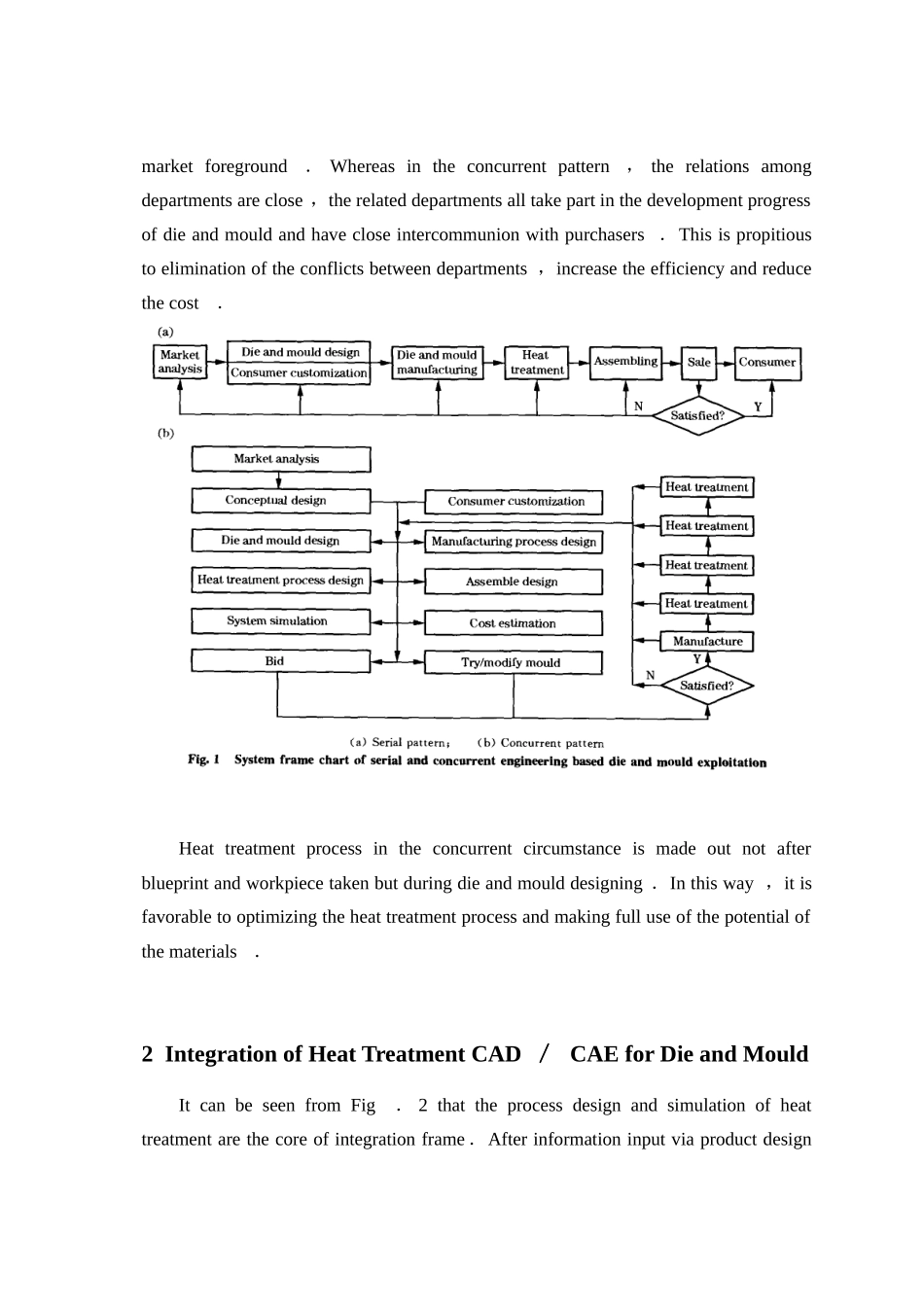

Heat Treatment of Die and Mould Oriented Concurrent DesignLI Xiong,ZHANG Hong-bing,RUAN Xue—yu,LUO Zhong—hua,ZHANG YanAbstract: Many disadvantages exist in the traditional die design method which belongs to serial pattern. It is well known that heat treatment is highly important to the dies. A new idea of concurrent design for heat treatment process of die and mould was developed in order to overcome the existent shortcomings of heat treatment process. Heat treatment CAD/CAE was integrated with concurrent circumstance and the relevant model was built. These investigations can remarkably improve efficiency, reduce cost and ensure quality of R and D for products.Key words:die design; heat treatment; mouldTraditional die and mould design,mainly by experience or semi—experience ,is isolated from manufacturing process.Before the design is finalized ,the scheme of die and mould is usually modified time and again,thus some disadvantages come into being,such as long development period,high cost and uncertain practical effect.Due to strong desires for precision,service life,development period and cost,modern die and mould should be designed and manufactured perfectly.Therefore more and more advanced technologies and innovations have been applied,for example,concurrent engineering,agile manufacturing virtual manufacturing,collaborative design,etc.Heat treatment of die and mould is as important as design,manufacture and assembly because it has a vital effect on manufacture ,assembly and service life.Design and manufacture of die and mould have progressed rapidly , but heat treatment lagged seriously behind them . As die and mould industry develops , heat treatment must ensure die and mould there are good state of manufacture...