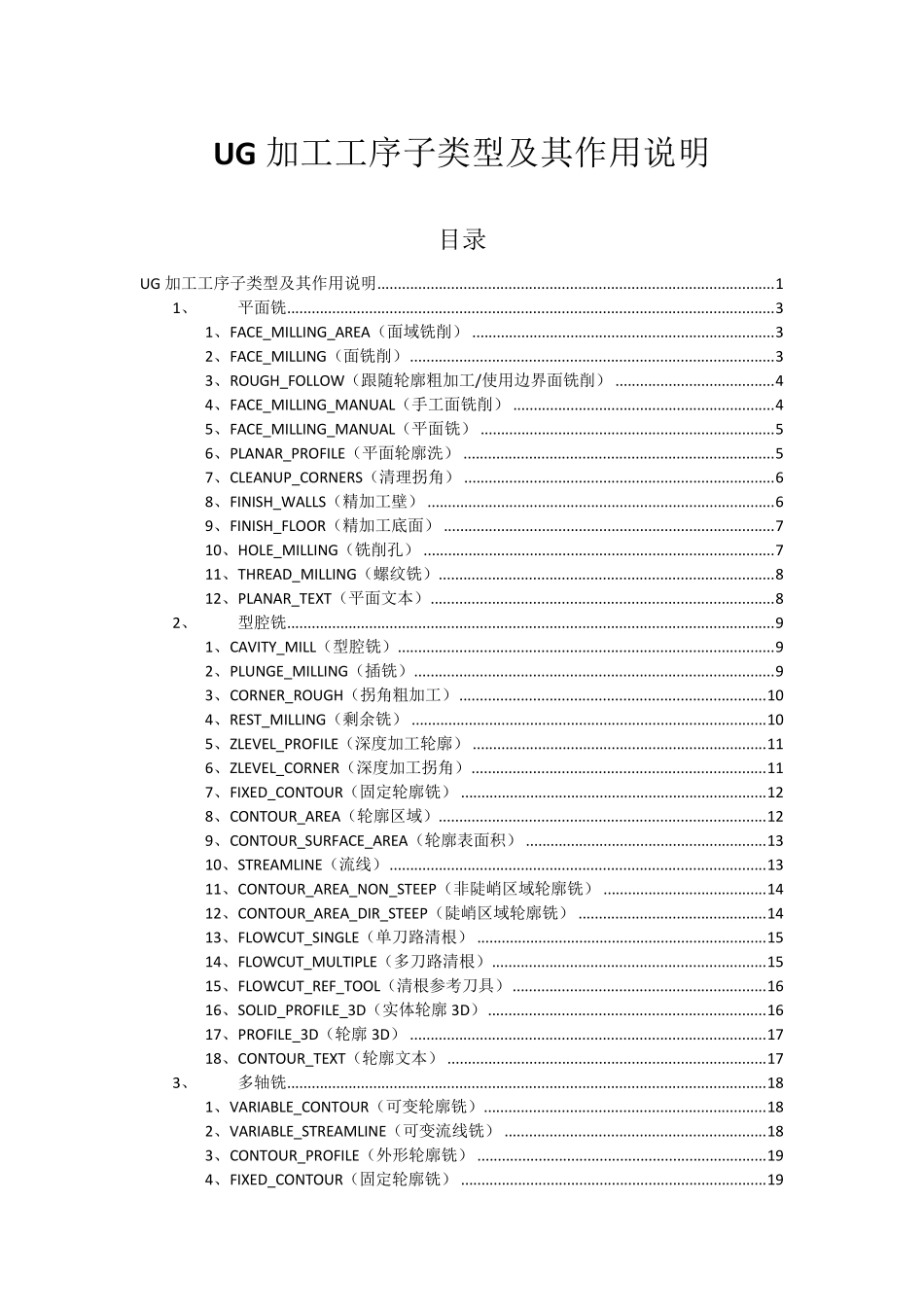

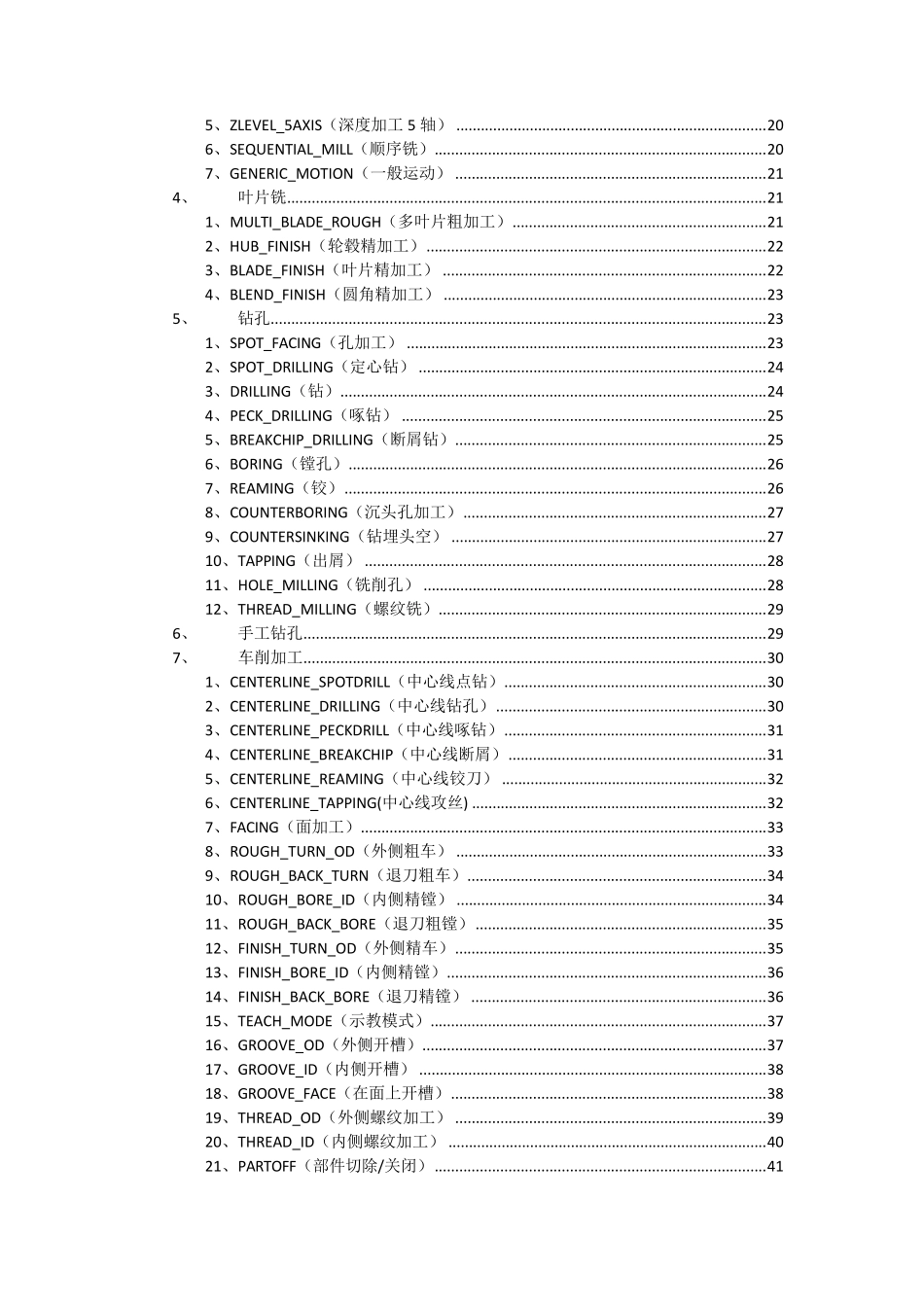

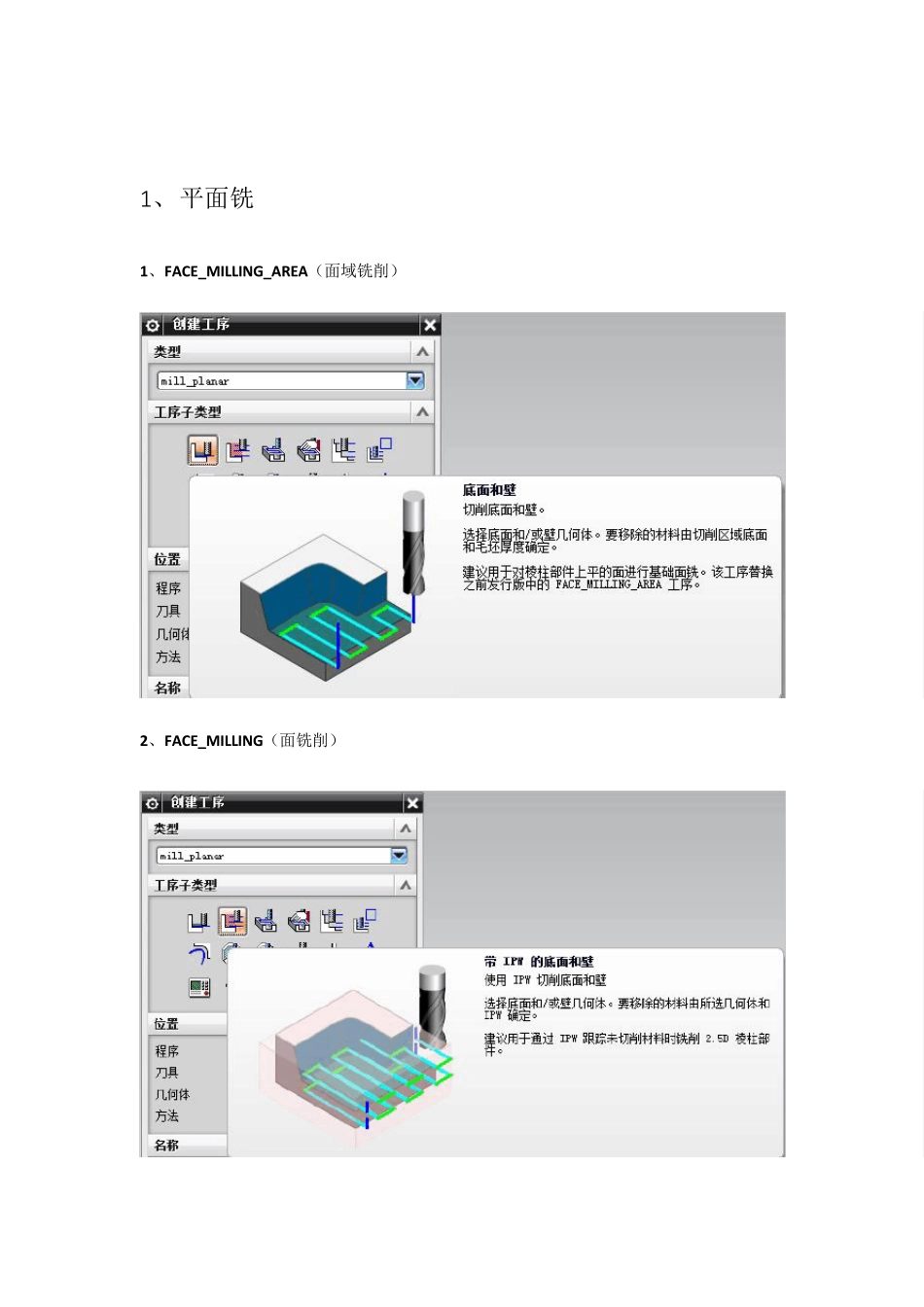

UG 加工工序子类型及其作用说明 目录 UG 加工工序子类型及其作用说明 ................................................................................................. 1 1、 平面铣 ....................................................................................................................... 3 1、FACE_MILLING_AREA(面域铣削) .......................................................................... 3 2、FACE_MILLING(面铣削) ......................................................................................... 3 3、ROUGH_FOLLOW(跟随轮廓粗加工/使用边界面铣削) ....................................... 4 4、FACE_MILLING_MANUAL(手工面铣削) ................................................................ 4 5、FACE_MILLING_MANUAL(平面铣) ........................................................................ 5 6、PLANAR_PROFILE(平面轮廓洗) ............................................................................ 5 7、CLEANUP_CORNERS(清理拐角) ............................................................................ 6 8、FINISH_WALLS(精加工壁) ..................................................................................... 6 9、FINISH_FLOOR(精加工底面) ................................................................................. 7 10、HOLE_MILLING(铣削孔) ...................................................................................... 7 11、THREAD_MILLING(螺纹铣) .................................................................................. 8 12、PLANAR_TEXT(平面文本) .................................................................................... 8 2、 型腔铣 ....................................................................................................................... 9 1、CAVITY_MILL(型腔铣)............................................................................................ 9 2、PLUNGE_MILLING(插铣) ...........................................