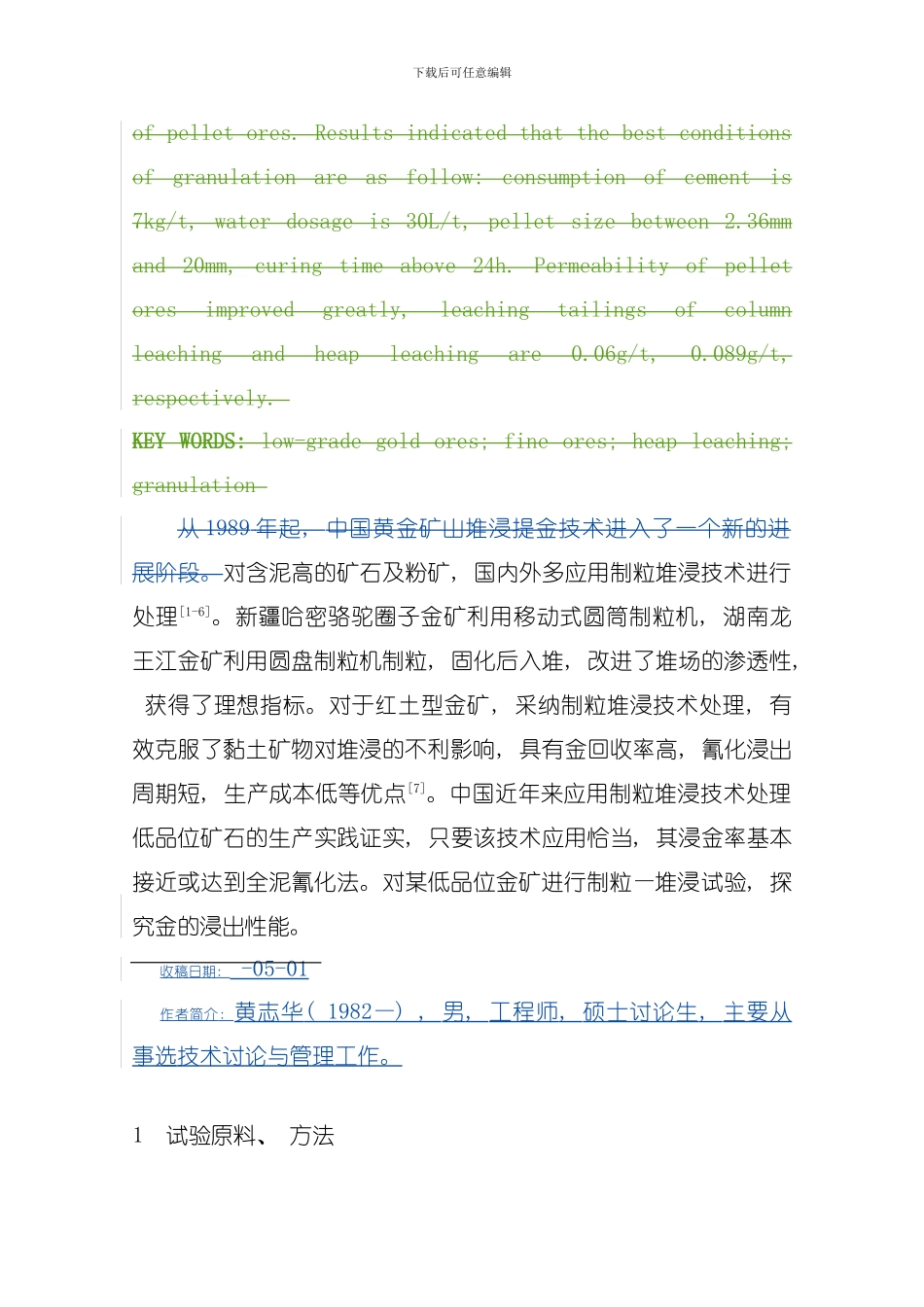

低品位金矿粉矿制粒—堆浸试验讨论黄志华, 李暑宏, 苏秀珠 ( 紫金矿业集团股份有限公司, 福建 上杭, 364200) 摘 要: 对某低品位金矿粉矿进行制粒-堆浸试验, 考察了固化剂、 固化剂用量、 水耗、 固化时间等对粉矿制粒的影响, 并对制粒矿进行堆浸试验, 探究制粒金矿粉矿的浸出性能。试验得到金矿粉矿制粒的最佳条件为: 水泥用量7kg/t, 水耗为 30L/t, 成球粒径+2.36mm-~20mm, 固化水分为 10%, 固化时间大于 24 小时 h。粉矿经制粒后渗透性大大提高, 柱浸试验尾渣金品位低于 0.07g/t, 堆浸试验尾渣金品位低于 0.089g/t, 浸出效果良好。为低品位金矿粉矿的处理提供了指导意义。关键词: 低品位金矿; 粉矿; 制粒; 堆浸 doi:10.3969/j.issn.1000-6532. .0x.00x中图分类号: TD925 文章编号: A 文献标识码: 1000-6532( ) 00RESEARCHES ON GRANULATION-HEAP LEACHING OF LOW-GRADE GOLD FINE ORES Huang Zhihua, Li Shuhong, Su Xiuzhu ( Zijin Mining Group Co., Ltd.Shanghang Fujian, 364200) ABSTRACT Researches on granulation-heap leaching of low-grade gold fine ores were carried out in this paper, granulation factors such as bonder, consumption, water dosage, and curing time were investigated, and heap-leaching tests were taken to identify leaching performance 下载后可任意编辑of pellet ores. Results indicated that the best conditions of granulation are as follow: consumption of cement is 7kg/t, water dosage is 30L/t, pellet size between 2.36mm and 20mm, curing time above 24h. Permeability of pellet ores improved greatly, leaching tailings of column leaching and heap leaching are 0.06g/t, 0.089g/t, respectively. KEY WORDS: low-grade gold ores; fine ores; heap leaching; granulation 从 1989 年起, 中国黄金矿山堆浸提金技术进入了一个新的进展阶段。对含泥高的矿石及粉矿, 国内外多应用制粒堆浸技术进行处理[1-6]。新疆哈密骆驼圈子金矿利用移动式圆筒制粒机, 湖南龙王江金矿利用圆盘制粒机制粒, 固化后入堆, 改进了堆场的渗透性, 获得了理想指标。对于红土型金矿, 采纳制粒堆浸技术处理, 有效克服...