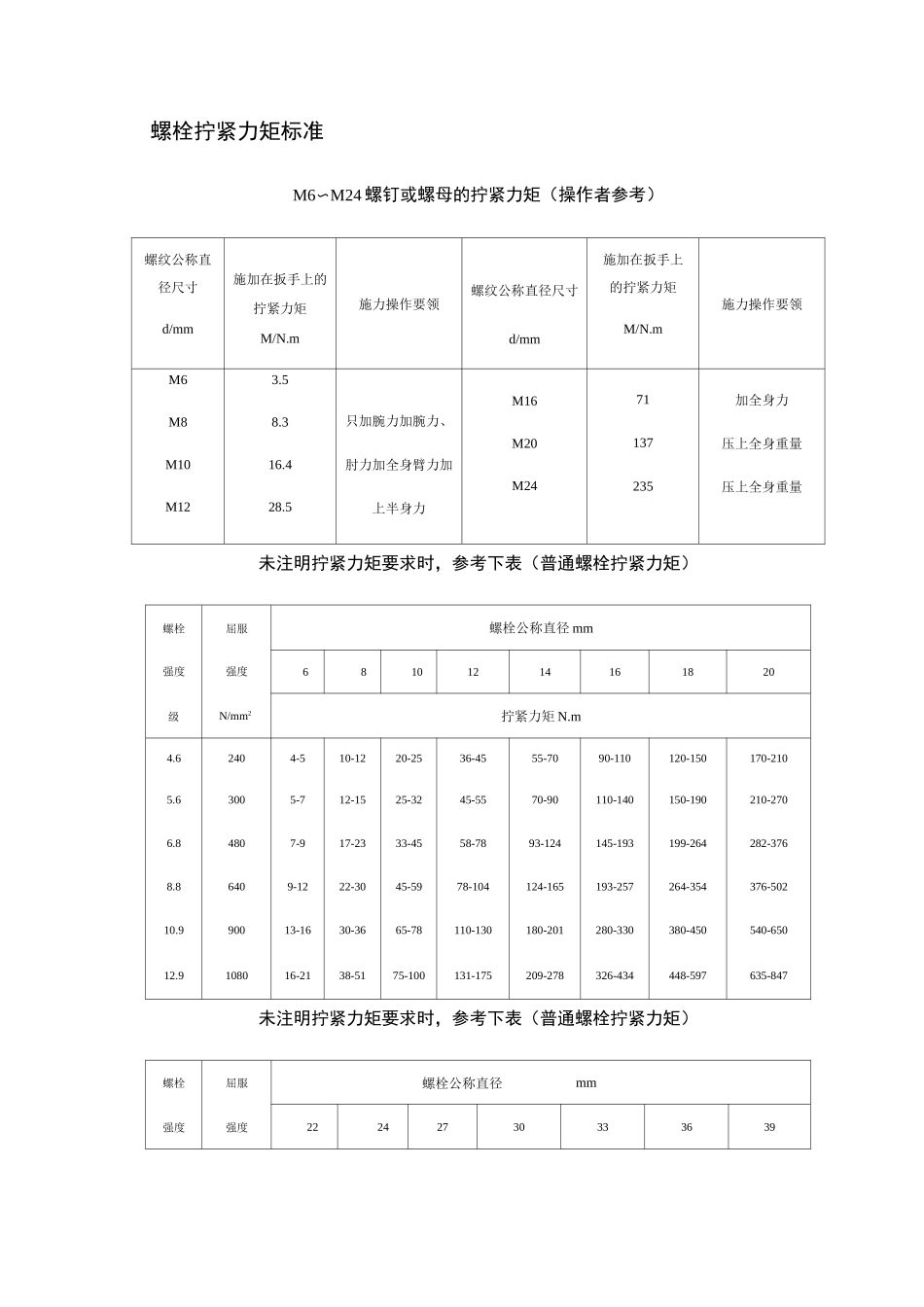

螺栓拧紧力矩标准M6〜M24 螺钉或螺母的拧紧力矩(操作者参考)螺纹公称直径尺寸d/mm施加在扳手上的拧紧力矩M/N.m施力操作要领螺纹公称直径尺寸d/mm施加在扳手上的拧紧力矩M/N.m施力操作要领M6M8M10M123.58.316.428.5只加腕力加腕力、肘力加全身臂力加上半身力M16M20M2471137235加全身力压上全身重量压上全身重量未注明拧紧力矩要求时,参考下表(普通螺栓拧紧力矩)螺栓强度屈服强度螺栓公称直径 mm68101214161820级N/mm2拧紧力矩 N.m4.62404-510-1220-2536-4555-7090-110120-150170-2105.63005-712-1525-3245-5570-90110-140150-190210-2706.84807-917-2333-4558-7893-124145-193199-264282-3768.86409-1222-3045-5978-104124-165193-257264-354376-50210.990013-1630-3665-78110-130180-201280-330380-450540-65012.9108016-2138-5175-100131-175209-278326-434448-597635-847未注明拧紧力矩要求时,参考下表(普通螺栓拧紧力矩)螺栓屈服螺栓公称直径mm强度强度22242730333639级N/mm2拧紧力矩 N.m4.6240230-290300-377450-530540-680670-880900-1100928-12375.6300290-350370-450550-700680-850825-11001120-14001160-15466.8480384-512488-650714-952969-12931319-17591694-22591559-20798.8640512-683651-868952-12691293-17231759-23452259-30122923-389810.9900740-880940-11201400-16501700-20002473-32982800-33504111-548112.91080864-11521098-14641606-21422181-29082968-39583812-50824933-6577范围:本标材料45、35CrM。或同等以上材料螺纹公称直径(mm)范围 Nm(kgfm)目标 Nm(kgfm)M68.8-14.7(0.9-1.5)12(1.2)M814.7-34(1.5-3.5)25(2.5)M1034-74(3.5-7.5)54(5.5).M1254-123(5.5-12.5)89(9.0)M1484-196(8.5-20)137(14)M16147-309(15.0-31.5)230(23.5)M18201-427(20.5-43.5)315(32)M20319-608(32.5-62.0)460(47)M22471-829(48.0-84.5)650(66.5)M24588-1030(60-105)810(82.5)M27883-1470(90-150)1180(120)M301130-1910(115-195)1520(155)M331470-2450(150-250)1960(200)M361860-3040(190-310)2450(250)M392260-3630(230-370)2940(300)★对于设计图纸有明确力矩要求的,应按图纸要求执行套管螺母紧固力矩 Q/STBB07833-1998材料 HPb63-3Y2尺寸代号0410(M10*1)0614(M14*1)0817(M18*1)紧固力矩 Nm3.14-4.906.86-13.76.86-9.81直通式压注油杯 Q/STBB07020-1998(螺纹 M6、M8*1、M10*1)安全阀 Q/STBB07029-1998(螺纹 R1/8)紧固力矩...