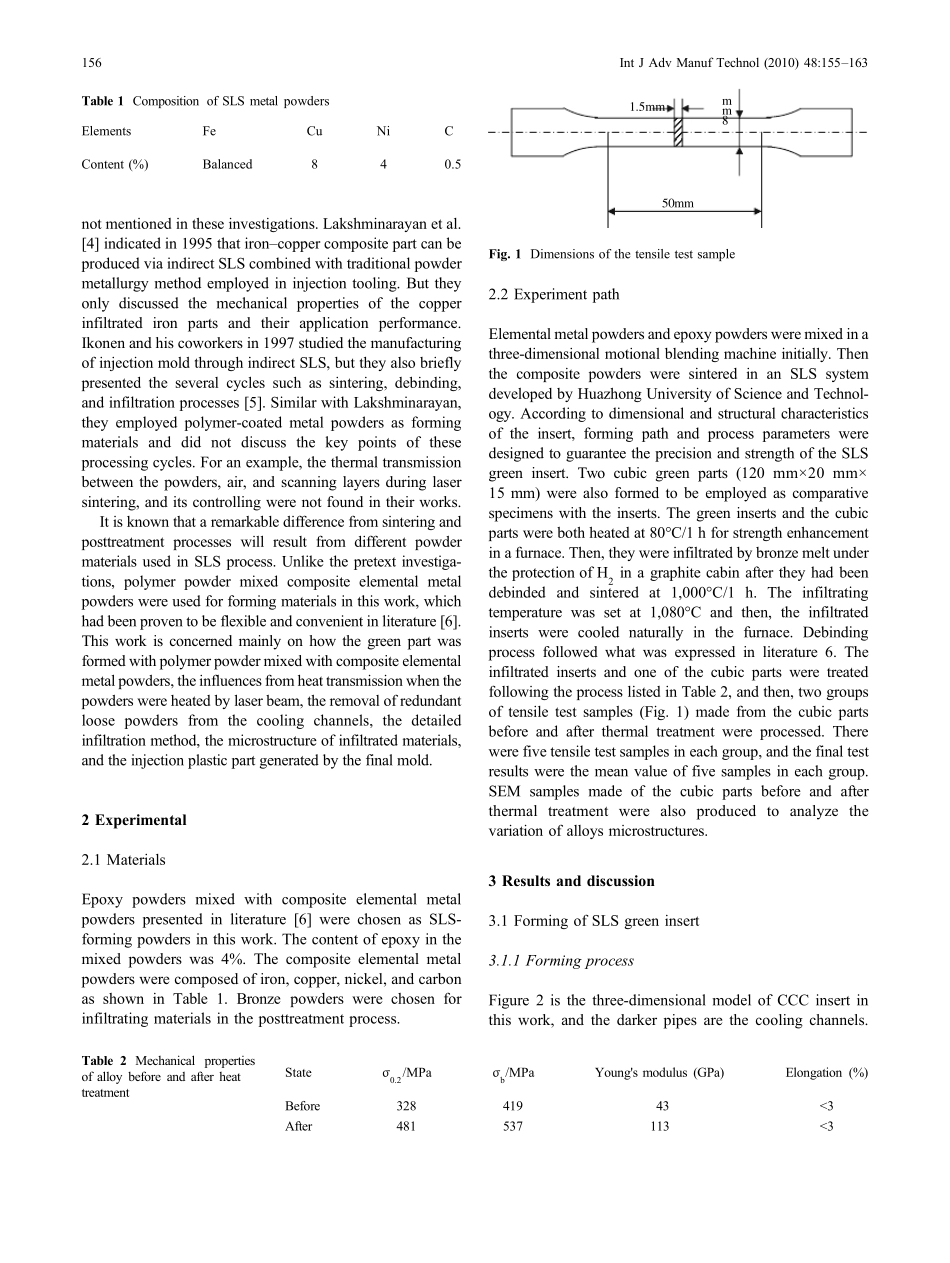

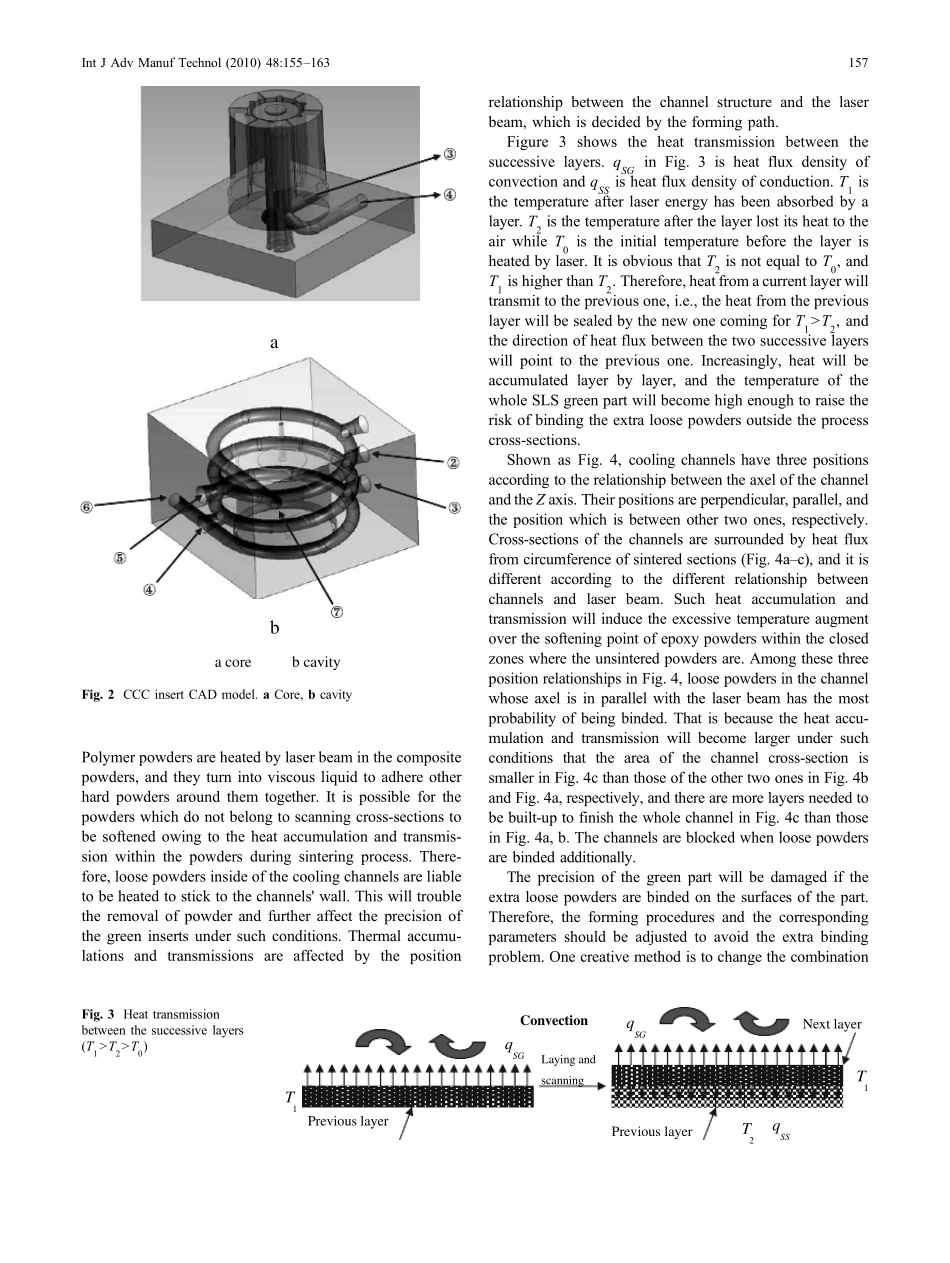

ORIGINAL ARTICLEInvestigation into manufacturing injection mold via indirectselective laser sinteringJinhui Liu & Zhongliang Lu & Yusheng Shi & Wenwu Xu &Jing ZhangReceived: 20 January 2009 /Accepted: 16 August 2009 /Published online: 8 September 2009# Springer-Verlag London Limited 2009Abstract Cooling system of an injection mold is importantfor the promotion of production rate and the quality ofinjection plastic components. Conformal cooling channelsare newly developed temperature-adjusting method topromote the efficiency of cooling system. They can be madein the injection mold inserts via the method of indirectselective laser sintering combined with traditional powdermetallurgy. This work discussed some processes such asthermal transmission, powders removing, and metal meltinfiltration during the manufacturing of the mold inserts indetail. The result showed that redundant powders outside oflaser-scanned areas might be sintered together with thesintered parts owing to the accumulation of laser energyduring sintering process. This was solved by switching thetemperature to initial level after one layer had been sintered.A limit length corresponding to some certain power vacuumsystem was found when the removal of unsintered powdersin the cooling channels was carried out. Therefore, somesubsidiary channels leading the cooling channels outsidewere made to help the removal of powders within the coolingchannels. Dripping method was adopted during metal meltinfiltration process, which was proven to be relevant formaintaining of the final shape of infiltrated inserts.Keywords Selective laser sintering . Injection mold .Conformal cooling channels . Manufacturing detail1 IntroductionThe production rate and the quality are much of a concerncur...