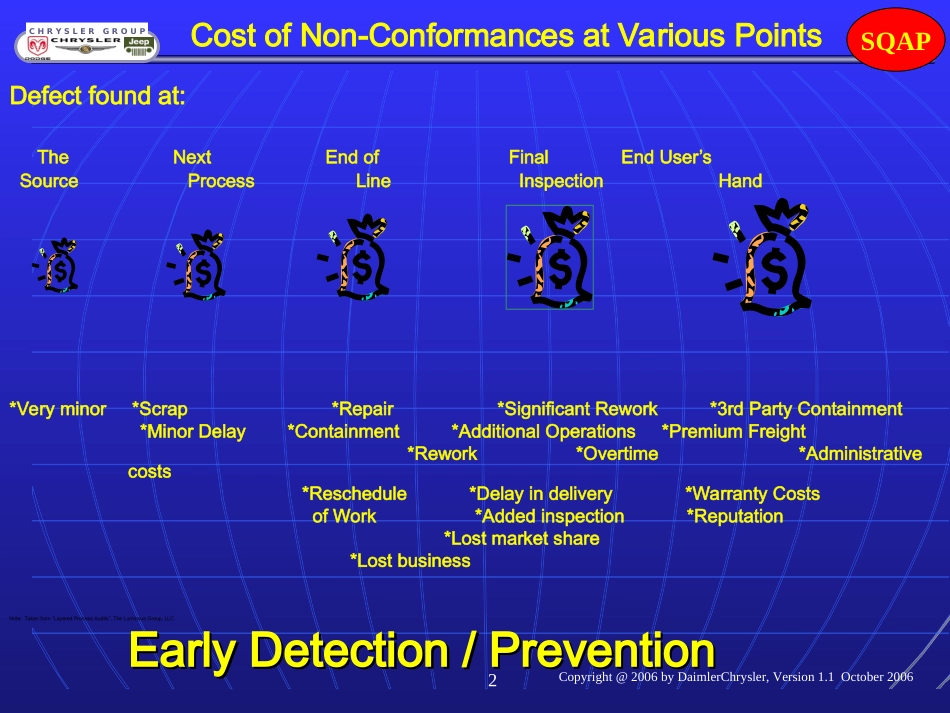

CHRYSLERGROUPCHRYSLERGROUP1Copyright@2006byDaimlerChrysler,Version1.1October2006LayeredProcessAudit(LPA)逐层过程审核(LPA)Element#16Element#16要素要素#16#16SQAP供应商质量保证程序CHRYSLERGROUPCHRYSLERGROUP2Copyright@2006byDaimlerChrysler,Version1.1October2006CostofNon-ConformancesatVariousPointsDefectfoundat:TheNextEndofFinalEndUser’sSourceProcessLineInspectionHand*Veryminor*Scrap*Repair*SignificantRework*3rdPartyContainment*MinorDelay*Containment*AdditionalOperations*PremiumFreight*Rework*Overtime*Administrativecosts*Reschedule*Delayindelivery*WarrantyCostsofWork*Addedinspection*Reputation*Lostmarketshare*LostbusinessNote:Takenfrom“LayeredProcessAudits”,TheLuminousGroup,LLCEarlyDetection/PreventionEarlyDetection/PreventionSQAPCHRYSLERGROUPCHRYSLERGROUP3Copyright@2006byDaimlerChrysler,Version1.1October2006在各阶段发生的不符造成的成本在以下阶段发现的缺陷:源头下个流程线末尾最终检验最终用户的手里*非常小*划伤*返修*大的返工*第三方的遏制*短时间延时*遏制*额外操作*昂贵的运输成本*返工*加班*管理成本*重订计划*延时发货*保修成本*增加检验次数*声誉*失去市场份额*失去业务Note:Takenfrom“LayeredProcessAudits”,TheLuminousGroup,LLC早期探测早期探测//预防预防SQAPCHRYSLERGROUPCHRYSLERGROUP4Copyright@2006byDaimlerChrysler,Version1.1October2006SupplierInterface–LPAisDCMandatoryRequirement供应商接口-逐层过程审核是戴克强制性要求ISO/TS16949DaimlerChryslerCustomerSpecificRequirements戴姆勒-克莱斯勒用户特殊要求NewsectionunderInternalAudits正对新章节进行内部审核Effective7/01/04forPowertrain&ComponentPlantssuppliers;动力总成及其零部件的供应商于7/01/04日开始执行;1/1/05forallremainingsuppliers对所有其余的供应商于1/1/05年开始执行PostedonAIAG,IAOB,andQMSwebsites在AIAG,IAOB,和QMS网站上发布Lettermailedtoallsuppliers信函已经发给了所有的供应商SQAPLPAisanewQualityTool.LPA是一项新的质量工具CHRYSLERGROUPCHRYSLERGROUP5Copyright@2006byDaimlerChrysler,Version1.1October2006ObjectivesObjectives目标目标•Knowledge知识BeabletoexplaintherationalebehindLPAs能够描述LPA的基本原理BeabletodescribehowtoconductLPAs能够描述如何开展LPABeabletodescribethebenefitsofLPAs能够描述LPA的益处•Skills技能BeabletotointegrateLPAsintoyourplant’squalitysystem能够将LPA纳入工厂的质量体系BeabletodevelopLPAchecksheet能够制定LPA检查清单BeabletoconductandLPAonthefactoryfloor能够在工厂内开展LPASQAPCHRYSLERGROUPCHRYSLERGROUP6Copyright@2006byDaimlerChrysler,Version1.1October20061.LayeredProcessAuditPlan1.LayeredProcessAuditPlan逐层过程审核计划逐层过程审核计划LPADefinitionsandRequirements逐层过程审核定义和要求逐层过程审核定义和要求LPABenefits逐层过程审核的益处逐层过程审核的益处LPAPlanLPAPlanLPALPA计划计划SQAPCHRYSLERGROUPCHRYSLERGROUP7Copyright@2006byDaimlerChrysler,Version1.1October2006WhatAreLayeredProcessAudits?WhatAreLayeredProcessAudits?什麽是什麽是逐层过程审核LayeredProcessAudits(LPA)areasystemofauditsperformedbymultiplelevelsofmanagement.Keyprocesscharacteristicsareauditedfrequentlytoverifyprocessconformance.逐层过程审核(LPA)是由多个管理层进行的系统审核。对关键过程特性进行频繁的审核以验证过程符合性。ThepurposeofLayeredProcessAuditsistoensurecontinuousconformance,therebyimprovingprocessstabilityandfirst-timethroughcapability.(AsrequiredbyChryslerGroupTSCustomerSpecifics(4.2.1.9.1)逐层过程审核的目的是确保持续的符合性,从而提高过程稳定性和一次通过率。(见克莱斯勒TS用户特殊要求4.2.1.9.1)SQAPLPADefinitionsandRequirements逐层过...