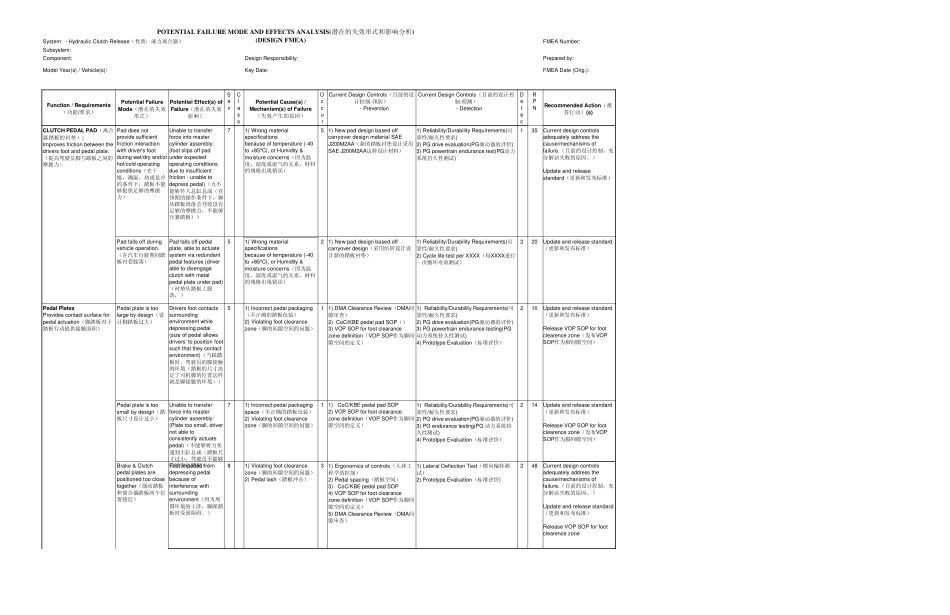

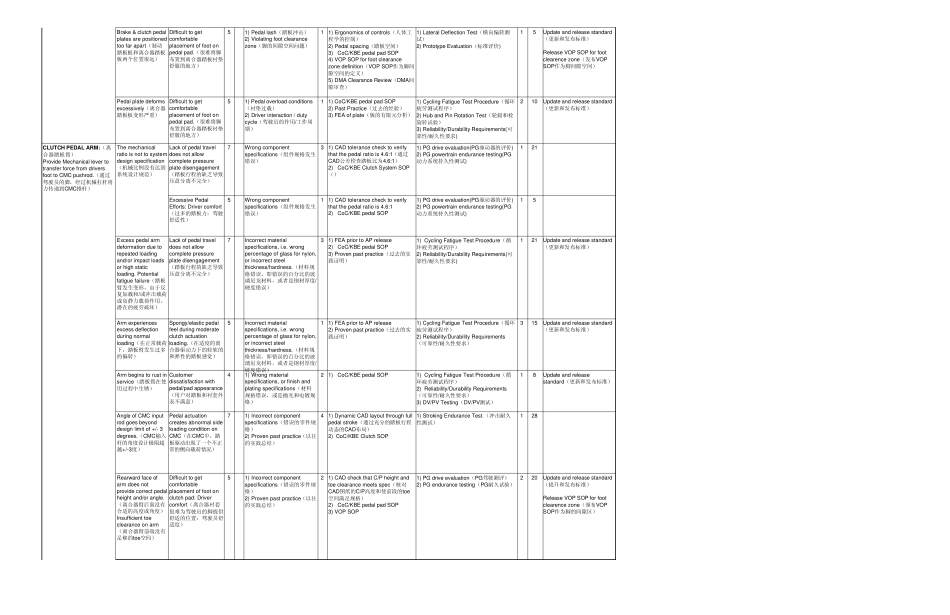

POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS(潜在的失效形式和影响分析)System: - Hydraulic Clutch Release(性质:液力离合器)(DESIGN FMEA)FMEA Number:Subsystem: Component: Design Responsibility: Prepared by: Model Year(s) / Vehicle(s): Key Date: FMEA Date (Orig.): CLUTCH PEDAL PAD(离合器踏板的衬垫):Improves friction between thedrivers foot and pedal plate.(提高驾驶员脚与踏板之间的摩擦力)Pad does notprovide sufficientfriction interactionwith driver's footduring wet/dry and/orhot/cold operatingconditions(在干燥,潮湿,热或是冷的条件下,踏板不能够提供足够的摩擦力)Unable to transferforce into mastercylinder assembly:(foot slips off padunder expectedoperating conditionsdue to insufficientfriction - unable todepress pedal)(力不能够传入总缸总成(在预期的操作条件下,脚从踏板滑落会导致没有足够的摩擦力,不能够压紧踏板))71) Wrong materialspecificationsbecause of temperature (-40to +85ºC), or Humidity &moisture concerns(因为温度,湿度或湿气的关系,材料的规格出现错误)51) New pad design based offcarryover design material SAEJ200M2AA(新的踏板衬垫设计采用SAE J200M2AA这种设计材料)1) Reliability/Durability Requirements(可靠性/耐久性要求)2) PG drive evaluation(PG驱动器的评价)3) PG powertrain endurance test(PG动力系统持久性测试)135Current design controlsadequately address thecause/mechanisms offailure.(目前的设计控制,充分解决失败的原因。)Update and releasestandard(更新和发布标准)Pad falls off duringvehicle operation.(在汽车行驶期间踏板衬套脱落)Pad falls off pedalplate, able to actuatesystem via redundantpedal features (driverable to disengageclutch with metalpedal plate under pad)(衬垫从踏板上脱落,)51) Wrong materialspecificationsbecause of temperature (-40to +85ºC), or Humidity &moisture concerns(因为温度,湿度或湿气的关系,材料的规格出现错误)21) New pad design based offcarryover design(采用结转设计设计新的踏板衬垫)1) Reliab...