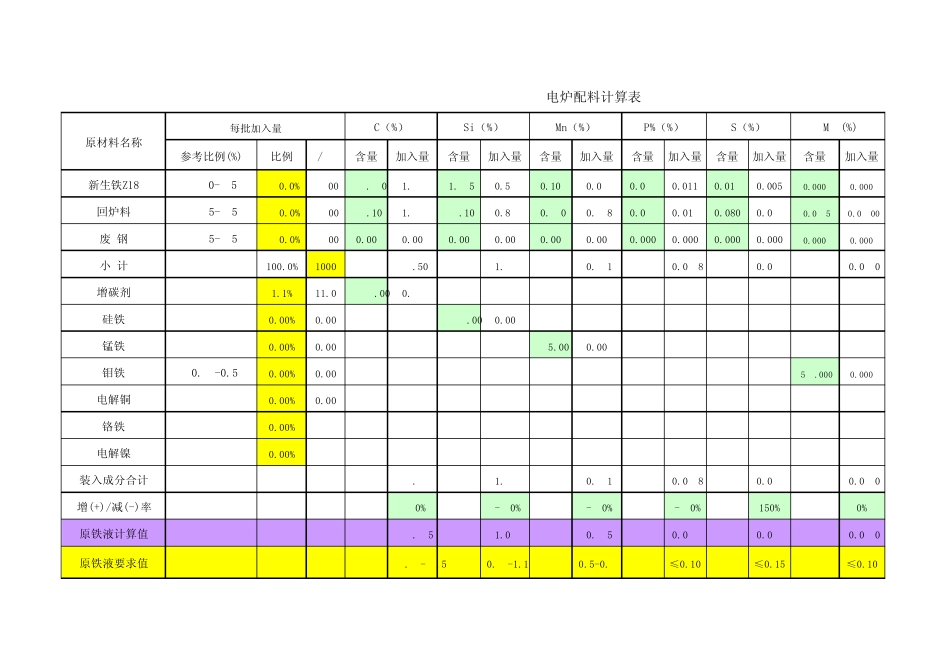

参考比例(%)比例/kg含量加入量含量加入量含量加入量含量加入量含量加入量含量加入量新生铁Z1830-3530.0%3004.201.261.750.530.100.030.036 0.0110.0170.0050.0000.000回炉料35-4540.0%4003.101.242.100.840.700.280.042 0.0170.0800.0320.0750.0300废 钢25-3530.0%3000.000.000.000.000.000.000.0000.0000.0000.0000.0000.000小 计100.0%10002.501.370.310.0280.0370.030增碳剂1.1%11.072.000.79硅铁0.00%0.0072.000.00锰铁0.00%0.0065.000.00钼铁0.2-0.50.00%0.0056.0000.000电解铜 0.00%0.00铬铁0.00%电解镍0.00%装入成分合计3.291.370.310.0280.0370.030增(+)/减(-)率20%-20%-20%-20%150%0%原铁液计算值3.951.090.250.0220.0930.030原铁液要求值3.2-3.50.9-1.10.5-0.9≤0.10≤0.15≤0.10原材料名称Mo(%)电炉配料计算表C(%)Si(%)Mn(%)P%(%)S(%)每批加入量孕育每包铁水重量/kg500参考比例(%)比例其中/kg含量加入量含量加入量含量加入量含量加入量含量加入量含量加入量原铁液计算值3.951.090.250.0220.0930.030一次孕育剂0.2-0.50.50%1.068.0 0.340二次孕育剂0.10%0.00%0.068.0 0.000随流孕育0.1-0.150.00%0.068.0 0.000孕育小计0.340孕育吸收率85%孕育加入量合计0.289孕育后铁液计算值合计3.951.380.250.0220.0930.030孕育后铁液要求值:3.2-3.51.8-2.30.5-0.9≤0.10≤0.15≤0.10孕育后铁液要求值按壁厚详细值:主要壁厚/mm<153.2-3.6/3.2-3.51.9-2.2/1.8-2.10.6-0.9/0.8-1.015-303.1-3.4/3.1-3.41.5-1.8/1.6-1.90.7-0.9/0.8-1.0碳当量4.413.9-4.2孕育处理Si(%)Mo(%)P%(%)C(%)≤0.12HT200/HT250S(%)Mn(%)每包加入量<0.1530-503.0-3.4/3.0-3.31.5-1.8/1.5-1.80.8-1.0/0.9-1.1>503.0-3.2/2.9-3.21.4-1.7/1.4-1.70.8-1.0/1.0-1.2计算说明:现场成份调整:≤0.12HT200/HT250基本公式:溶质=溶液*浓度。(元素是溶质,铁液是溶液,含量是浓度)如碳要求含量为3.9%,实测为3.6%,需加入含碳量0.3%.1、基本公式:元素加入量=加入百分数*元素含量。如生铁碳含量4.2%,配入量是70%,则生铁配入的碳含量=70%*4.2%=2.94%。2、元素的增减率或吸收率按不同熔炼情况,按实际确定,输入表中即可。<0.15含量加入量含量加入量含量加入量0.0000.0000.0000.0000.3500.1400.2200.0880.2200.0880.0000.0000.0000.0000.1400.0880.088100.0000.00060.0000.000100.0000.0000.1400.0000.0880%0%0%0.1400.0000.0880.2-0.4≤0.250.1-0.25Cr(%)Ni(%)Cu(%)含量加入量含量含量0.1400.0000.0880.1400.0000.0880.2-0.4≤0.250.1-0.25Cu(%)Ni(%)Cr(%)