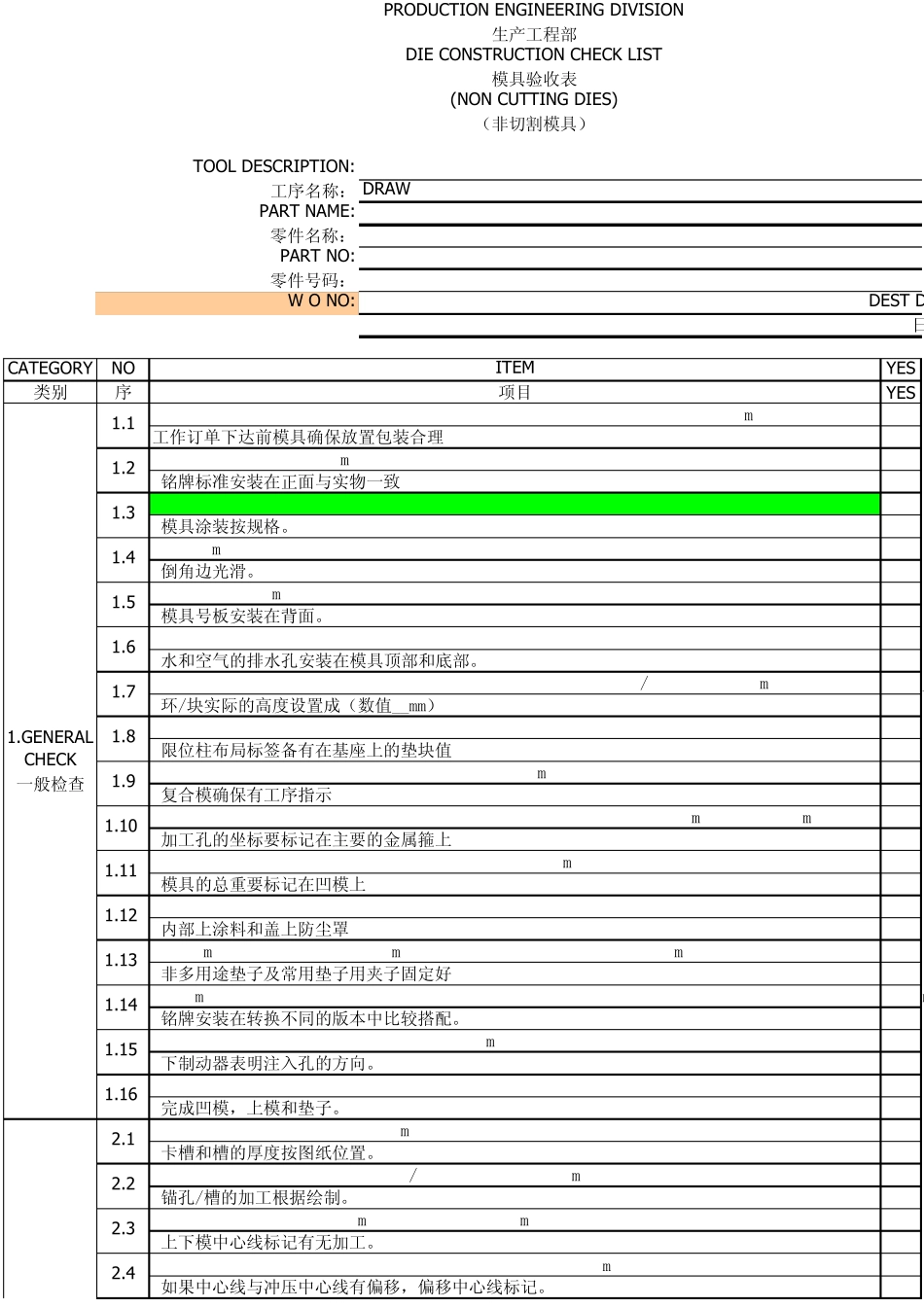

DRAWDEST D日CATEGORY NOYES类别序YES1.51.61.71.151.162.12.22.32.41.11.21.31.41.GENERALCHECK一般检查1.81.91.101.111.121.131.14 下制动器表明注入孔的方向。 Finishing of lower die,top die and pad is done. 完成凹模,上模和垫子。 Position of clamping slots and thickness of slots as per drawing. 铭牌安装在转换不同的版本中比较搭配。 Direction of feed os marked on lower shoe. 卡槽和槽的厚度按图纸位置。 Anchoring holes/slots are machined as per drewing. 锚孔/槽的加工根据绘制。 Centerlines marked and machined on lowwr die and top die. 如果中心线与冲压中心线有偏移,偏移中心线标记。 上下模中心线标记有无加工。 If centerlines are offset from press centerlines,offset centerlines are marked. Nameplate for conversion in different version comp.is fitted. 限位柱布局标签备有在基座上的垫块值 Indication of stages in multi stage dies is done. 复合模确保有工序指示 Co-ordinates of tooling holes stamped on master shoes. 模具的总重要标记在凹模上 Cores insides are painted and covered with dust covers. 内部上涂料和盖上防尘罩 No multiple shims are used and Shims used are fixed with clamping. 加工孔的坐标要标记在主要的金属箍上 Total weight of die is stamped on lower die. Actual height of setting rings/blocks made(Value_____mm) 环/块实际的高度设置成(数值__mm) Cushion pins lay out label fitted with value of cushion above base. Water and air drain holes provided on top and bottom die. 铭牌标准安装在正面与实物一致 Die painted as per specifications. 模具涂装按规格。 Chamfering of edges where necessary is done. 非多用途垫子及常用垫子用夹子固定好 Standard nameplate fitted in front side with all rows filled as per 倒角边光滑。 Tool number plate fitted at rear side. 模具号板安装在背面。ITEM项目 Work Order No and fornt of the die stamped on shoes.工作订单下达前模具确保放置包装合理 水和空气的排水孔安装在模...