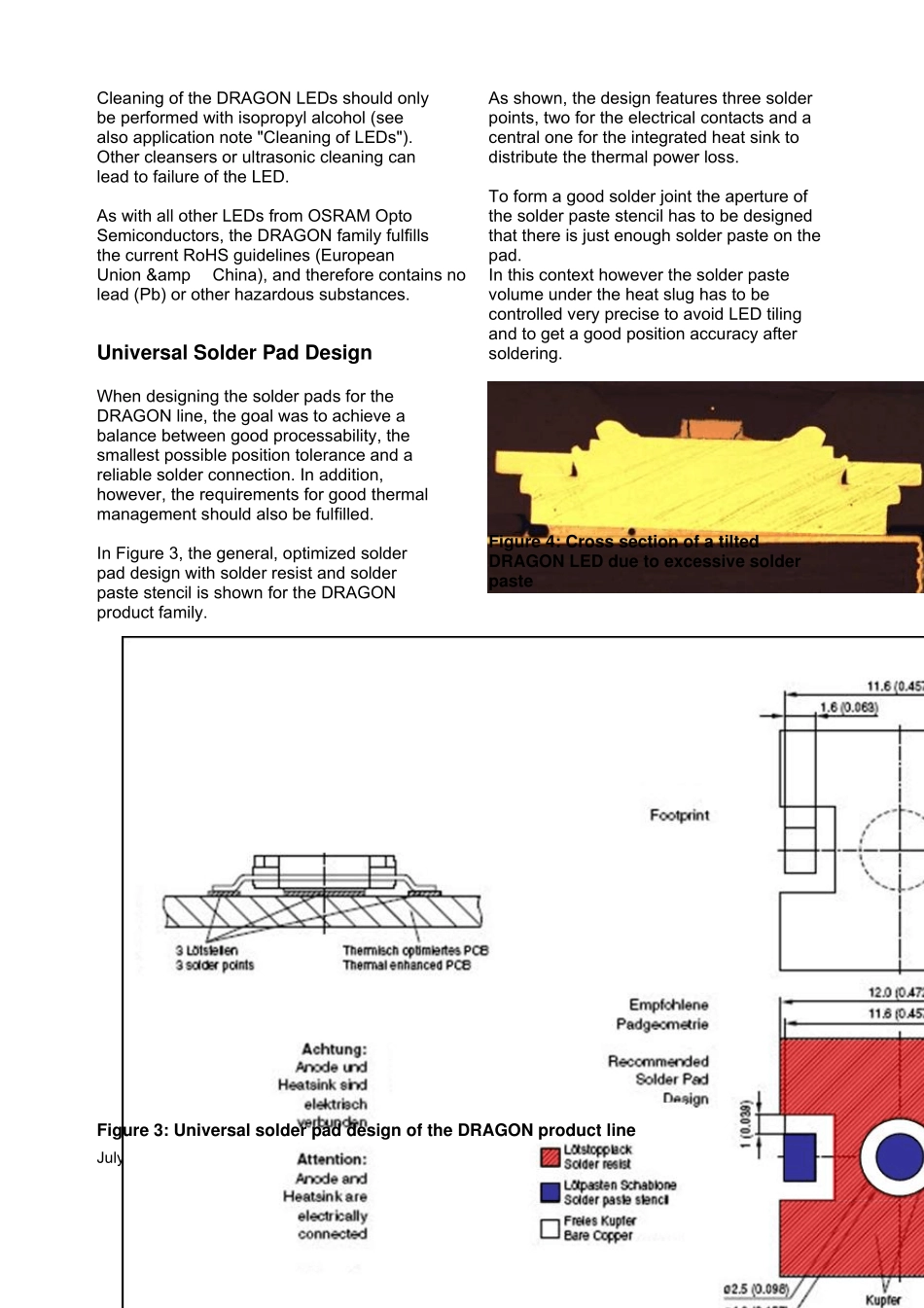

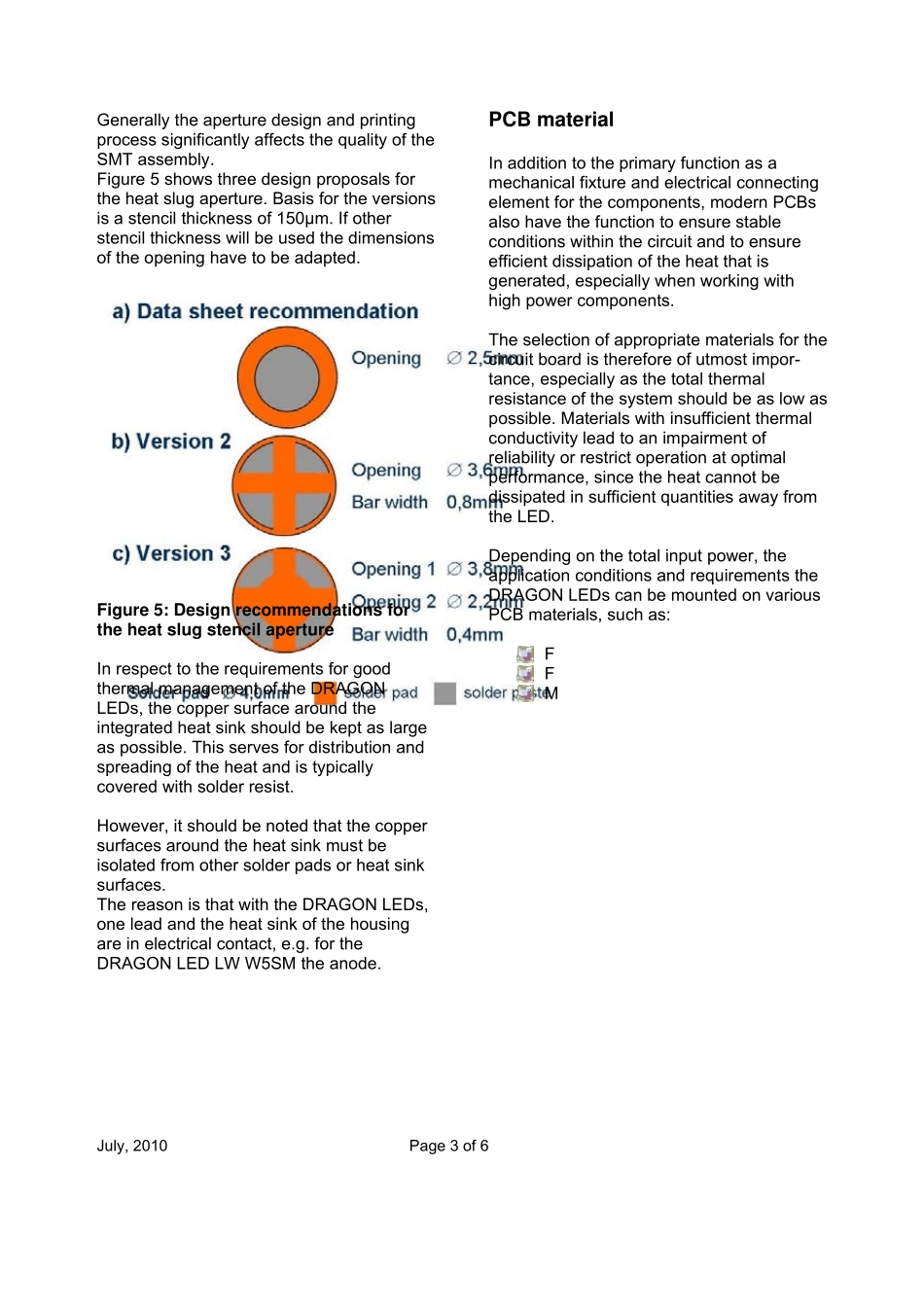

July, 2010 Page 1 of 6 General Information on the Assembly and Solder Pad Design of the DRAGON Family Application Note Abstract This application note gives general informa-tion on the assembly and design of the solder pad of the DRAGON product family. Suitable PCB materials will also be described. DRAGON LED product family The DRAGON product family has primarily been developed for applications in which there is a need for maximum light combined with small space requirements and furthermore the highest requirements in terms of life time. With their performance and design, the DRAGON LEDs (Fig. 1) are suitable for many diverse lighting and illumination application areas. The design of the DRAGON product family is based on a shared, thermally optimized housing concept – consisting of a prefabri-cated plastic housing with integrated heat sink, which acts as a heat spreader, and connection contacts (Fig. 2). Figure 2: Principle design of the DRAGON LEDs One of the advantages of this concept is that the products are interchangeable within the product line, which consequently increases the customer's flexibility due to the identical design of the solder pads. With one circuit board layout, for example, several applications with different brightness requirements can be implemented. Designed for high-volume production, the DRAGON LEDs are compatible with existing industrial SMT processing methods and it can be soldered by means of lead-free reflow technology. Figure 1: Overview of the DRAGON product family July, 2010 Page 2 of 6 Cleaning of the DRAGON LEDs should only be performed with isopropyl alcohol (see also application note "Cleaning of LEDs"). Other cleansers or ultrasonic cleaning can lead to failure...