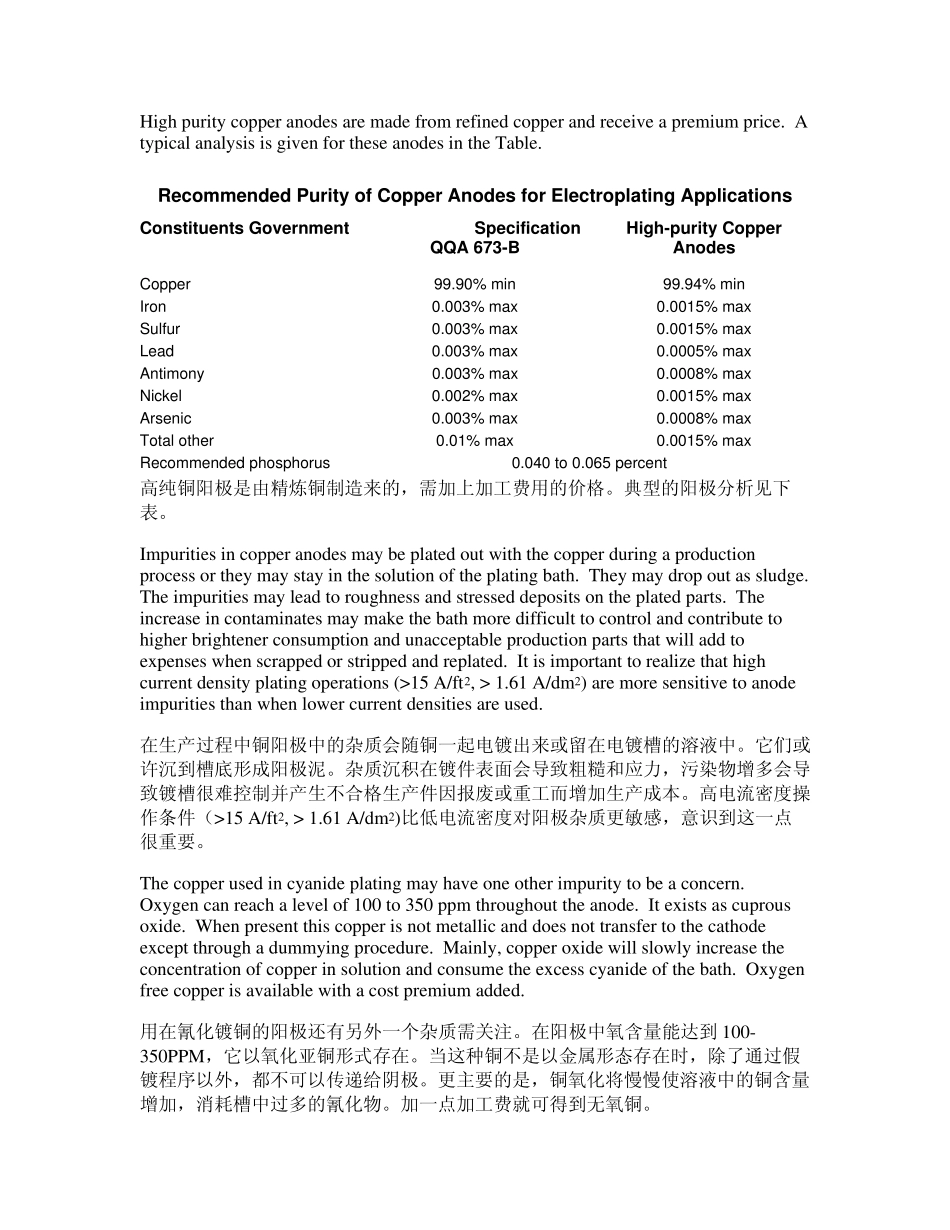

What Makes a Copper Anode Perform? 如何制造高质量的铜阳极 By Robert A. Berger, Ph.D. and W. Chuck Walker Copper anodes are typically used in acid or alkaline plating applications. While numerous methods have been used to improve the properties of the deposit on the cathode, many of the concepts behind the proper use of anodes were not well understood. After much investigation certain requirements are now recognized as essential to the manufacture of copper anodes. The use of pure feedstock, the determination of grain sizing, phosphorus content, and cleanliness have been shown to give consistently high results while reducing the number of variables that affect the complexity of a plating bath. 铜阳极通常用在酸性或碱性电镀工艺中。 虽然使用许多方法来提高阴极电镀层的性能,但在正确使用阳极方面的许多观念还不能很好的接受。经过大量的调查发现, 对铜阳极生产者来说,某些要求是必不可少的。即纯物料的使用,晶粒大小的决定,磷含量和清洁度, 这些因素已证明会得到始终如一的好结果,而缺少其中任一元素都会影响电镀槽的电镀品质。 When we consider what makes a copper plating bath work properly, there are several issues that have an important aspect. The cathode surface properties are affected by current density, brighteners, leveling agents, solution conductivity, distance from the anode, suspended particles, etc. It is the responsibility of the anode manufacturer to provide a copper anode to act as the source of copper that supports the various bath additives. 这儿有几个因素是影响铜槽正常运行的重要方面。影响阴极表面镀层性能的因素有电流密度,光亮剂,整平剂,溶液导电性,阴极到阳极距离,悬浮颗粒等。阳极制造业者的职责就是提供铜阳极以作为铜资源来支持不同的槽添加剂。 There are two general types of copper that provide a suitable source of copper for making anodes. The first type is essentially ...