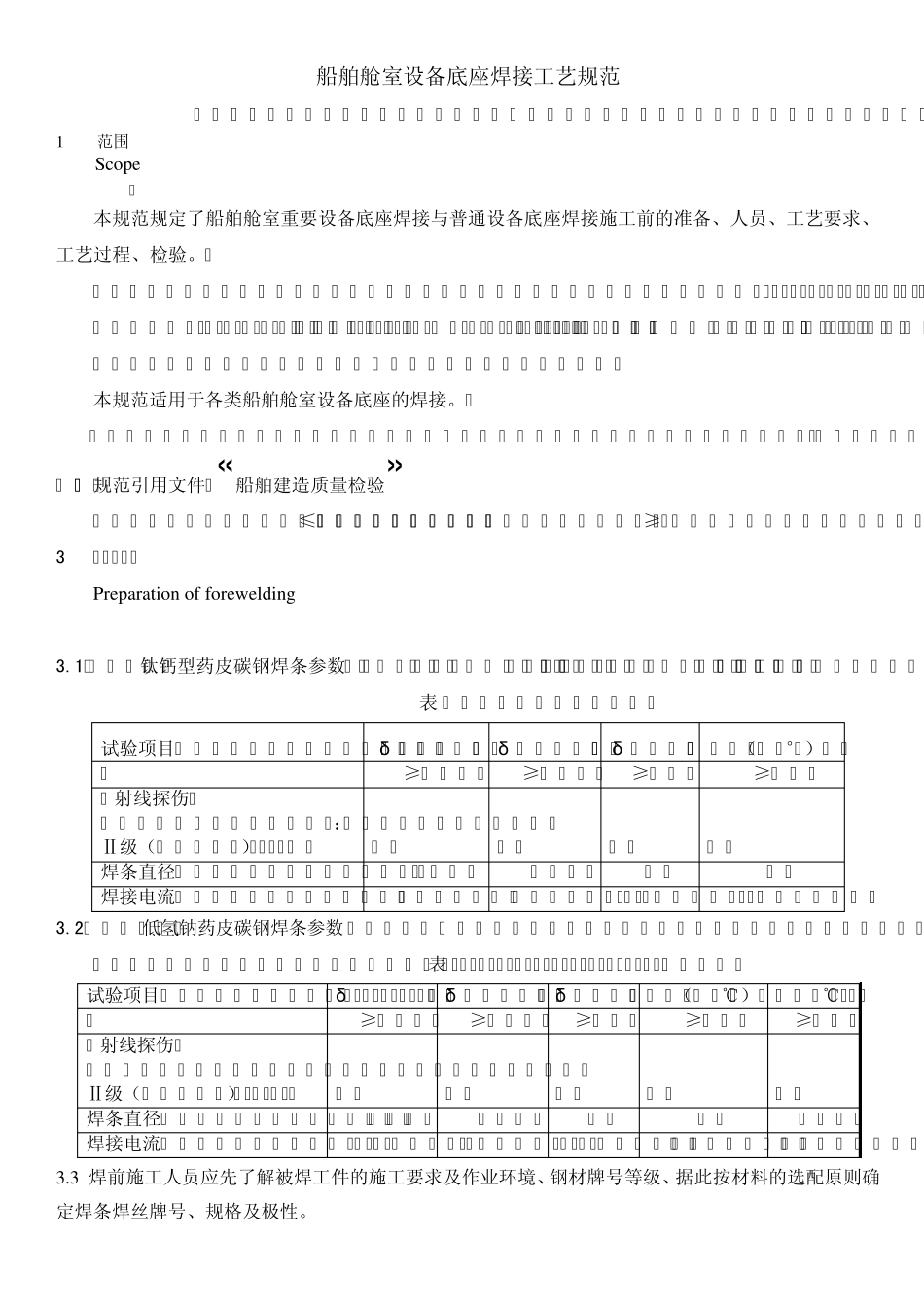

船舶舱室设备底座焊接工艺规范 WELDING PROCEDURE SPECIFICATION FOR EQUIPMENT BASE OF HULL CABIN 1 范围 Scope 本规范规定了船舶舱室重要设备底座焊接与普通设备底座焊接施工前的准备、人员、工艺要求、工艺过程、检验。 The specification rules the requirements of forewelding to preparation , personnel ,technological requirements ,technology process ,examination ;which are for base of important equipments and common equipments of hull cabin . 本规范适用于各类船舶舱室设备底座的焊接。 The specification apply to the welding for equipment base of diversified hull cabin . 2 规范引用文件 «船舶建造质量检验» Referring to document ≤QUALITY INSPECTION OF SHIPBUILDING ≥ 3 焊接前准备 Preparation of forew elding 3.1 CJ422钛钙型药皮碳钢焊条参数( CJ422 parameters for C steel electrode of Ti and Ca covering) 表3.1-1(form) 试验项目(Test project) δ s(Mpa) δ b(Mpa) δ 5(%) AKV(-20°)J ≥330 ≥420 ≥22 ≥47 X射线探伤 (Radiographic inspection):Ⅱ级(Grade two) 焊条直径(MM) Diameter 2.5 3.2 4 5 焊接电流(A) Current 60~110 120~150 160~210 220~270 3.2 CJ507低氢钠药皮碳钢焊条参数 (CJ422 parameters for C steel electrode of low hydrogen Na covering ) 表3.2-1(form) 试验项目(Test project) δ s(Mpa) δ b(Mpa) δ 5(%) AKV(-20℃) J(-30℃) ≥400 ≥490 ≥22 ≥47 ≥27 X射线探伤 (Radiographic inspection) Ⅱ级(Grade two) 焊条直径(MM) Diameter 2.5 3.2 4 5 5.8 焊接电流(A) Current 60~110 120~150 160~210 220~270 210~260 3.3 焊前施工人员应先了解被焊工件的施工要求及作业环境、钢材牌号等级、据此按材料的选配原则确定焊条焊丝牌号、规格及极性。 Welder should know about the welding requirements ,environment ,brand and grand of steel before welding .According to that ,to decide the brand ,size of electrode and wire and polarity on the principle of choosing material . 3.4 定位焊 Tack welding 3.4....