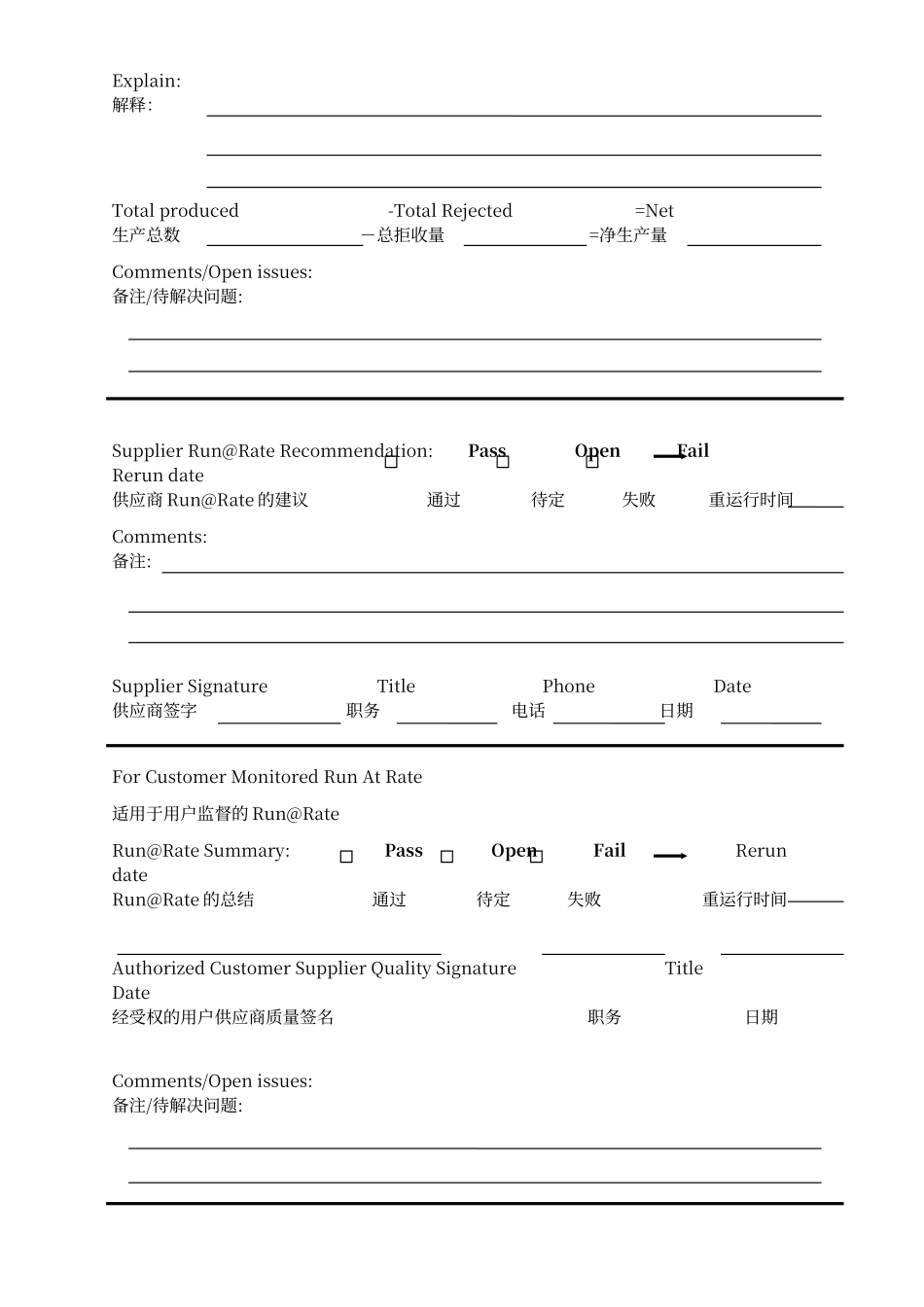

节 拍 生 产 评 审 报 告(GP9) Supplier供应商制造地址DUNsSupplier Quoted production rate供应商报价生产能力 /Hr 小时 /Day 天 Customer Buyer Phone用户 采购员 电话Planned usage: Daily weekly SQE Phone计划要货率: 每天 每周 质量工程师 电话 Planned Run Date计划运行日期Planned Hours to run计划运行小时数Planned Shifts Planned downtime计划班次 计划停工时间Reason for Planned Downtime计划停工的原因RESULTS 结果Actual hours From To实际小时数 从 至Actual shifts Date实际班数 日期Actual Downtimes (Planned & unplanned)实际停工时间 (计划和非计划)Part Name零件名称Part#零件号Drawing#图号Change Level更改级别 Goal (net good parts) 目标(合格零件净数) /hour 小时 /shift 班 /day 天 Actual (net good parts) 实际(合格零件净数) /hour 小时 /shift 班 /day 天1 OF 2Explain:解释: Total produced -Total Rejected =Net生产总数 -总拒收量 =净生产量Comments/Open issues:备注/待解决问题:Supplier Run@Rate Recommendation: Pass Open Fail Rerun date供应商 Run@Rate 的建议 通过 待定 失败 重运行时间Comments:备注:Supplier Signature Title Phone Date供应商签字 职务 电话 日期For Customer Monitored Run At Rate适用于用户监督的 Run@RateRun@Rate Summary: Pass Open Fail Rerun dateRun@Rate 的总结 通过 待定 失败 重运行时间Authorized Customer Supplier Quality Signature Title Date经受权的用户供应商质量签名 职务 日期Comments/Open issues:备注/待解决问题: 2 of 2RUN@RATE WORKSHEET GP-9节拍生产评审工作表Supplier Name: P/N:供应商名称: 零件号:RUN@RATE REVIEW CONTENTRun@Rate 检查内容The Run@Rate,will verify that the results of the supplier 抯 actual manufacturing process meet customer requirements for ongoing quality, as stated in PPAP, and quoted tooling capability. Also it will verify that supplier 抯 actual process is to plan, as document in PPAP, GP-12 and other documentation listed below.Run@Rate 是要核实供应商现行的生产过程之结果/成...