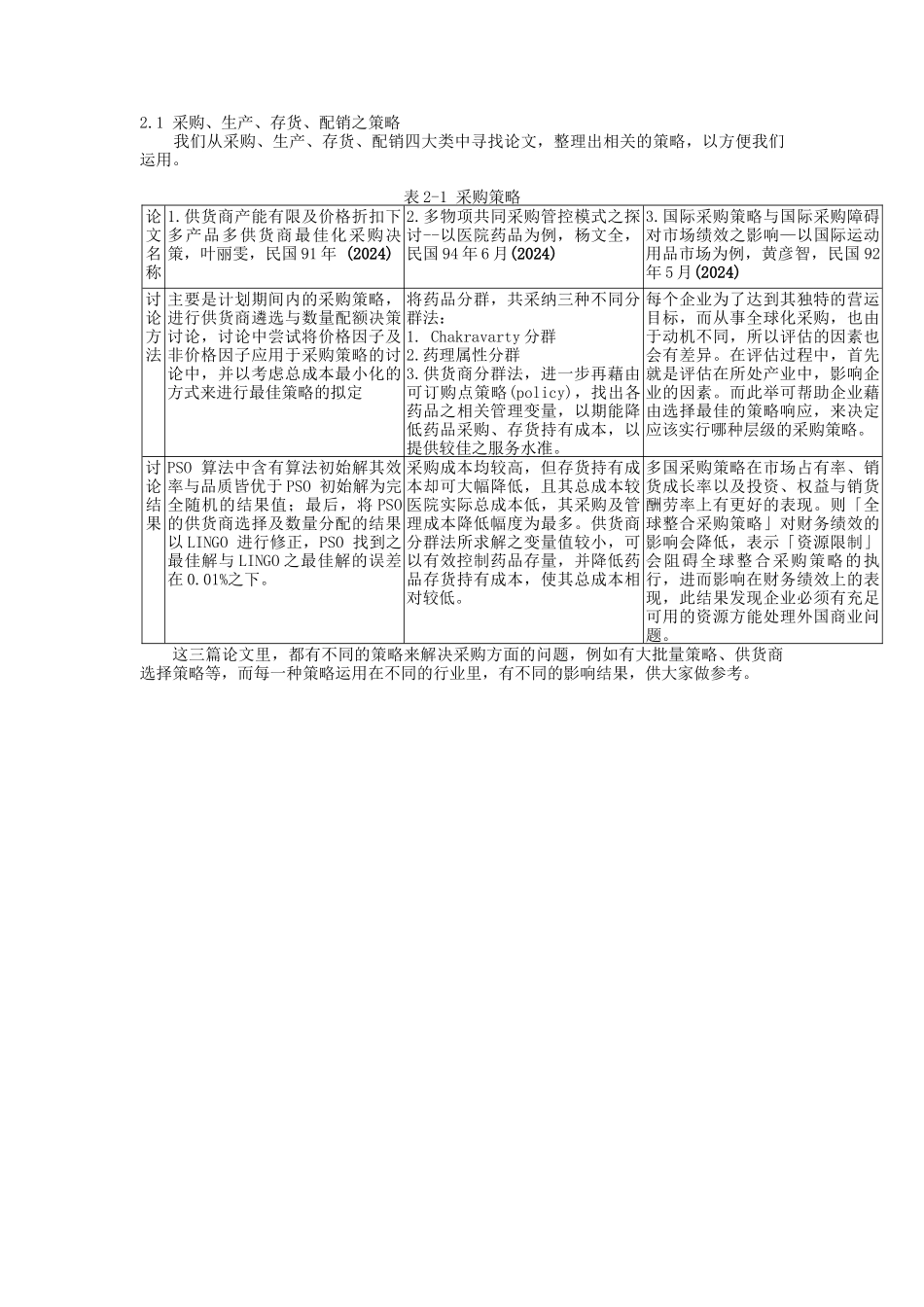

供应链中采购到配销的最佳策略--以汽车保险杆为例The optimal strategies from purchasing to distributing in Supply Chain- part bumper bar of the automobile蔡振芳 1威振八芳小组 21真理大学工业管理学系副教授 2真理大学工业管理学系专题小组中文摘要一个完整的供应链管理是流程整合的程序。供应链的上下游交易关系始于采购原料的行为到生产完成品至仓库,而后收到订单出货的配销部份,这整个交易过程牵涉的是交易双方组织内不同部门的彼此配合。在近十年来的全球竞争之环境下,迎接企业的挑战是在最适当的时间、地点,以最低的运送成本,将最高品质的产品或服务送到顾客手上,制造公司开始体会到策略性或合作性之供货商或顾客关系的重要性。就以汽车零件保险杆为例,我们以福并公司做为讨论对象,探讨这间工厂里在采购链、生产链、存货链、配销链四个链中可能会发生的问题,利用鱼骨图先分析问题产生的起始,进而分析策略下,对整体有利的决策。我们藉由敏感度分析来了解四个链当中各项成本对于总成本之影响程度。经由LINGO 求解,进一步探讨降低成本对供应链之影响及降低总成本之效益。最后,将推导出的成本数学模式藉由 LINGO 的撰写并搭配相关参数,即可搜寻到总成本的最佳解。关键词:供应链管理、敏感度分析、LINGOAbstractSupply Chain Management provides the multi-stage integrations for the global operations among the chain members. It begins with the material of chasing and ends with receiving the payment for finished products. The whole operating process involves the dynamic cooperation of optimizing functions on both sides (Supply & Demand).Under the environment of global competition in the past ten years, it is in the most proper time, place to meet the growing challenge of enterprises; the cost reduction of material production and transportation; and the quality improvement of new products for customer demands. The sub-contractors begin to realize the importance of cooperative relations between suppliers and customers. Taking part bumper bar of the automobile as a case study, we applied the product des...