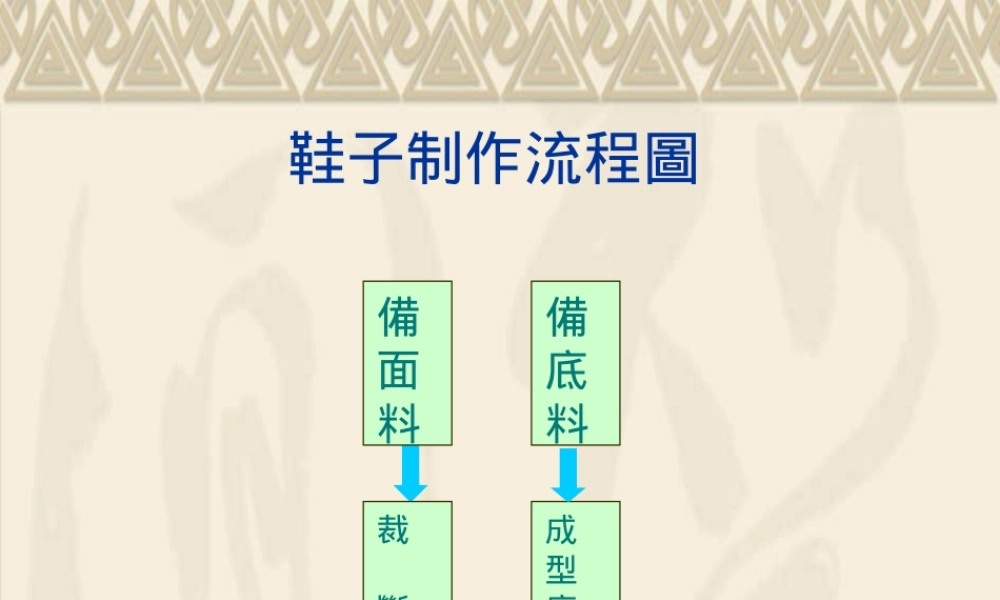

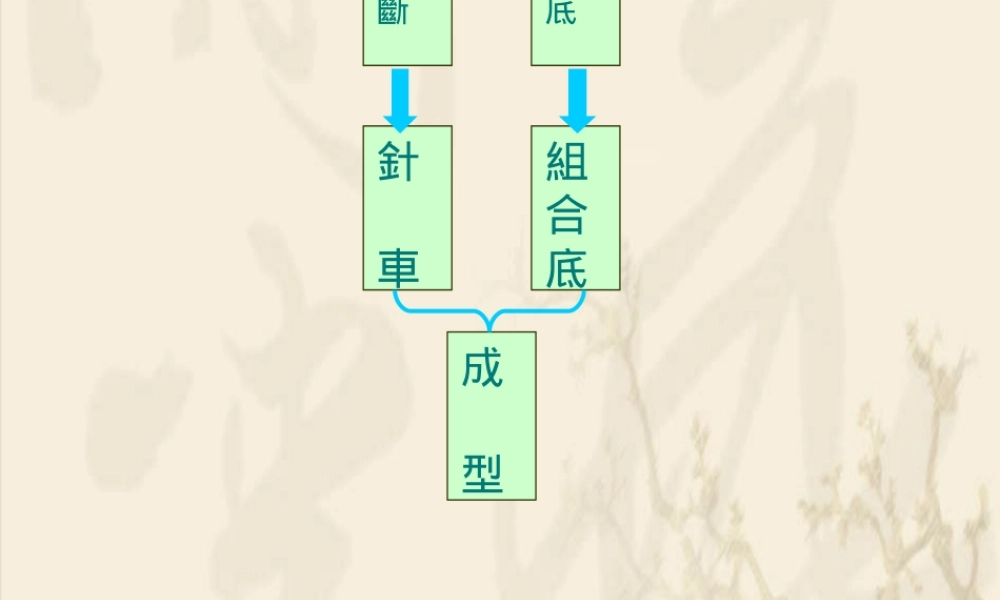

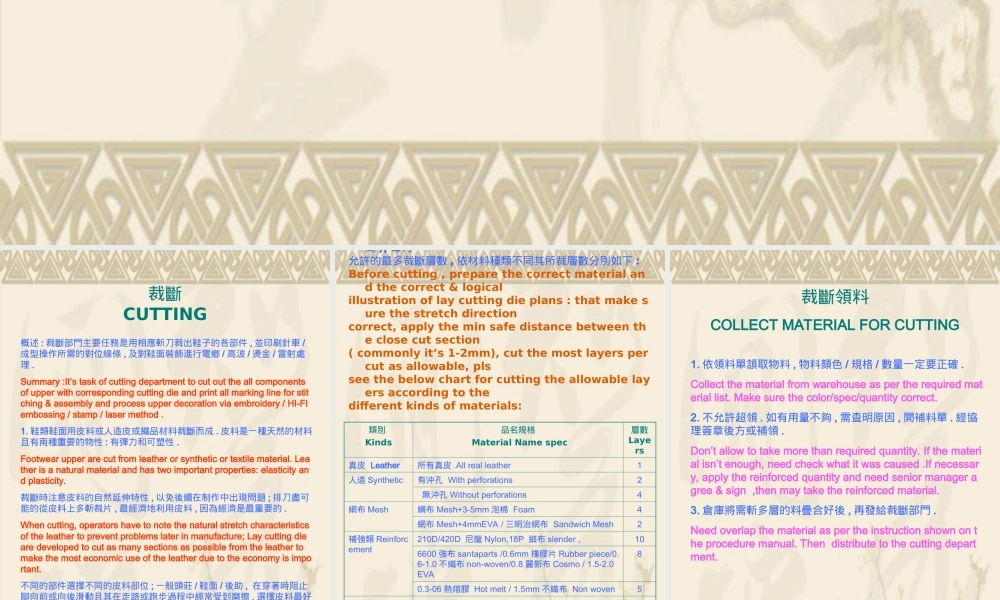

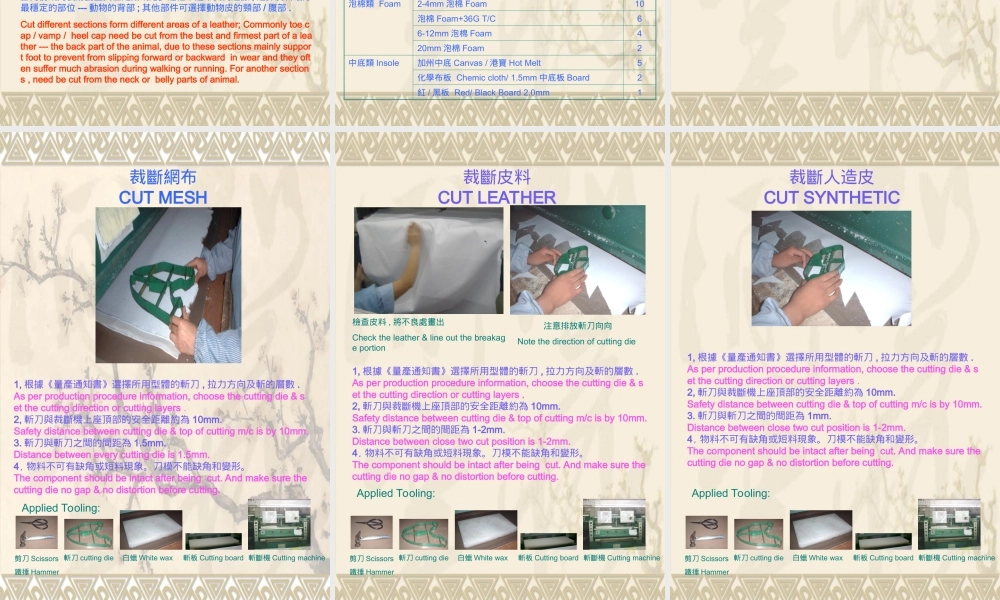

鞋子制作流程圖備面料備底料裁斷針車成型成型底組合底 裁斷CUTTING概述 : 裁斷部門主要任務是用相應斬刀裁出鞋子的各部件 , 並印刷針車 /成型操作所需的對位線條 , 及對鞋面裝飾進行電鄉 / 高波 / 燙金 / 雷射處理 .Summary :It’s task of cutting department to cut out the all components of upper with corresponding cutting die and print all marking line for stitching & assembly and process upper decoration via embroidery / HI-FI embossing / stamp / laser method .1. 鞋類鞋面用皮料或人造皮或織品材料裁斷而成 . 皮料是一種天然的材料且有兩種重要的物性 : 有彈力和可塑性 .Footwear upper are cut from leather or synthetic or textile material. Leather is a natural material and has two important properties: elasticity and plasticity.裁斷時注意皮料的自然延伸特性 , 以免後續在制作中出現問題 ; 排刀盡可能的從皮料上多斬裁片 , 最經濟地利用皮料 , 因為經濟是最重要的 .When cutting, operators have to note the natural stretch characteristics of the leather to prevent problems later in manufacture; Lay cutting die are developed to cut as many sections as possible from the leather to make the most economic use of the leather due to the economy is important.不同的部件選擇不同的皮料部位 ; 一般頭莊 / 鞋面 / 後助 , 在穿著時阻止腳向前或向後滑動且其在走路或跑步過程中經常受到磨擦 , 選擇皮料最好最穩定的部位 --- 動物的背部 ; 其他部件可選擇動物皮的頸部 / 腹部 .Cut different sections form different areas of a leather; Commonly toe cap / vamp / heel cap need be cut from the best and firmest part of a leather --- the back part of the animal, due to these sections mainly support foot to prevent from slipping forward or backward in wear and they often suffer much abrasion during walking or running. For another sections , need be cut from the neck or belly parts of animal. 2. 裁斷前先選擇...