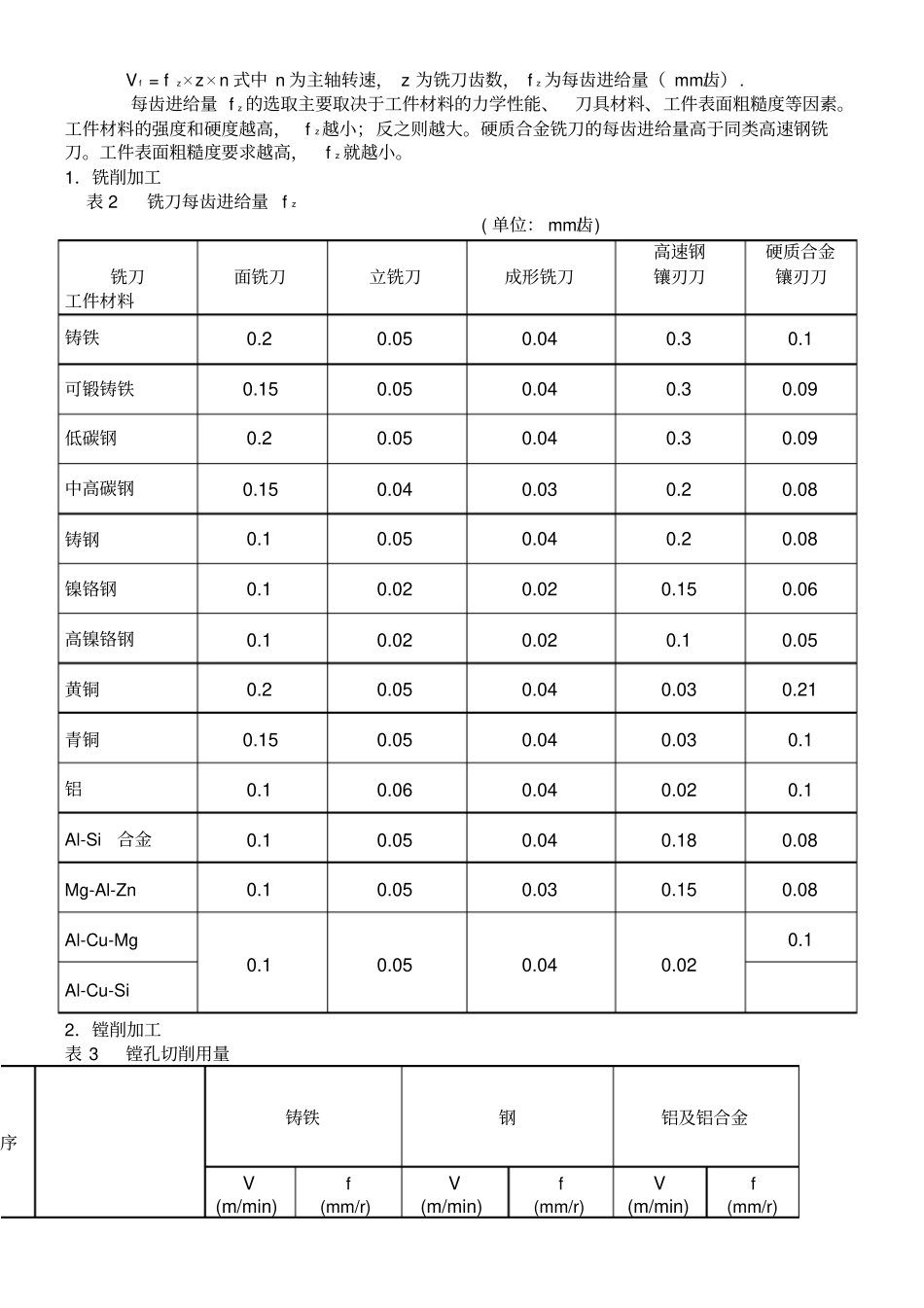

一、主轴转速n(r/min)主轴转速一般根据切削速度V来选定,计算公式为:n=1000V/(π×d)式中,d为刀具直径(mm),V为刀具切削速度(m/min)。对于球头铣刀,工作直径要小于刀具直径,故其实际转速应大于计算转速n。表1铣刀的切削速度V(单位:m/min)工件材料铣刀材料碳素钢高速钢超硬高速钢硬质合金碳化钛碳化钨铝合金75~150180~300300~600镁合金180~270150~600硬铝合金45~100120~190黄铜(软)12~2520~25100~180青铜10~2020~4060~130青铜(硬)10~1515~2040~60铸铁(软)10~1215~2018~2575~100铸铁(硬)10~1510~2045~60冷硬铸铁10~1530~60可锻铸铁10~1520~3025~4075~110钢(低碳)10~1418~2820~3045~70钢(中碳)10~1515~2518~2840~60钢(高碳)10~1512~2030~45合金钢35~80合金钢(硬)30~60高速钢12~2545~70二、进给速度Vf(mm/min)Vf=fz×z×n式中n为主轴转速,z为铣刀齿数,fz为每齿进给量(mm/齿).每齿进给量fz的选取主要取决于工件材料的力学性能、刀具材料、工件表面粗糙度等因素。工件材料的强度和硬度越高,fz越小;反之则越大。硬质合金铣刀的每齿进给量高于同类高速钢铣刀。工件表面粗糙度要求越高,fz就越小。1.铣削加工表2铣刀每齿进给量fz(单位:mm/齿)铣刀工件材料面铣刀立铣刀成形铣刀高速钢镶刃刀硬质合金镶刃刀铸铁0.20.050.040.30.1可锻铸铁0.150.050.040.30.09低碳钢0.20.050.040.30.09中高碳钢0.150.040.030.20.08铸钢0.10.050.040.20.08镍铬钢0.10.020.020.150.06高镍铬钢0.10.020.020.10.05黄铜0.20.050.040.030.21青铜0.150.050.040.030.1铝0.10.060.040.020.1Al-Si合金0.10.050.040.180.08Mg-Al-Zn0.10.050.030.150.08Al-Cu-Mg0.10.050.040.020.1Al-Cu-Si2.镗削加工表3镗孔切削用量序铸铁钢铝及铝合金V(m/min)f(mm/r)V(m/min)f(mm/r)V(m/min)f(mm/r)镗高速钢20~250.2~0.625~300.2~0.6100~1500.5~1.5硬质合金30~351~1.535~550.2~0.6100~2500.8~1.5精镗高速钢20~350.15~0.4525~350.1~0.5100~2000.2~0.5硬质合金50~700.2~0.555~850.15~0.55120~3000.3~0.6镗高速钢22~400.08~0.3525~370.1~0.35120~2500.1~0.4硬质合金70~900.12~0.3560~800.15~0.35150~4000.1~0.43、攻螺纹攻螺纹前底孔直径的确定:攻米制螺纹螺距P<1mm:d0=d-PP>1mm:d0=d-(1.04~1.06)P式中P—螺距(mm)d0—钻头直径(mm)d—螺纹公称直径(mm)攻不通孔螺纹钻孔深度=所需螺孔深度-0.7d表4攻普通螺纹前的底孔直径螺纹公称直径d螺距P钻头直径d0铸铁、青铜黄铜、铝及铝合金钢、紫铜可锻铸铁20.40.251.61.751.61.752.50.450.352.052.152.052.1530.50.352.52.652.52.6540.70.53.33.53.33.550.80.54.14.54.24.5610.754.95.255.281.256.66.710.756.97.177.2101.51.2510.758.48.68.99.18.58.799.2121.751.51.25110.110.410.610.910.210.510.711螺纹公称直径d螺距P钻头直径d0铸铁、青铜黄铜、铝及铝合金钢、紫铜可锻铸铁1421.5111.812.412.91212.5131621.5113.814.414.91414.515182.521.5115.315.816.416.915.51616.517202.521.5117.317.818.418.917.51818.519222.521.5119.319.820.420.919.52020.52124321.5120.721.822.422.9212222.523表5攻英制螺纹前的底孔直径公称直径/㎜非螺纹密封管螺纹英制锥管螺纹英制锥螺纹每25.4㎜内的牙数钻头直径/㎜每25.4㎜内的牙数钻头直径/㎜每25.4㎜内的牙数钻头直径/㎜1/8288.8288.4278.61/41911.71911.21811.13/81915.21914.71814.51/21418.91418.31417.93/41424.41423.61423.211130.61129.71129.211∕41139.21138.31137.913∕81141.611∕21145.11144.11143.921155.81156表6攻螺纹切削速度(单位:m/min)工件材料铸铁钢及合金钢铝及铝合金切削速度V2.5~51.5~55~154、钻孔加工表7用高速钢钻头钻孔切削用量(f单位:mm/r)工件材料牌号或硬度切削用量钻头直径1~66~1212~2222~50铸铁HB160-200V16~24f0.07~0.120.12~0.20.2~0.40.4~0.8HB200-241V10~18f0.05~0.10.1~0.1800.18~0.250.25~0.4HB300-400V5~12f0.03~0.080.08~0.150.15~0.20.2~0.3钢35、45V8~25f0.05~0.10.1~0.20.2~0.30.3~0.4515Cr、40CrV12~30f0.05~0.10.1~0.20.2~0.30.3~0.45合金钢V8~18f0.03~0.080.08...