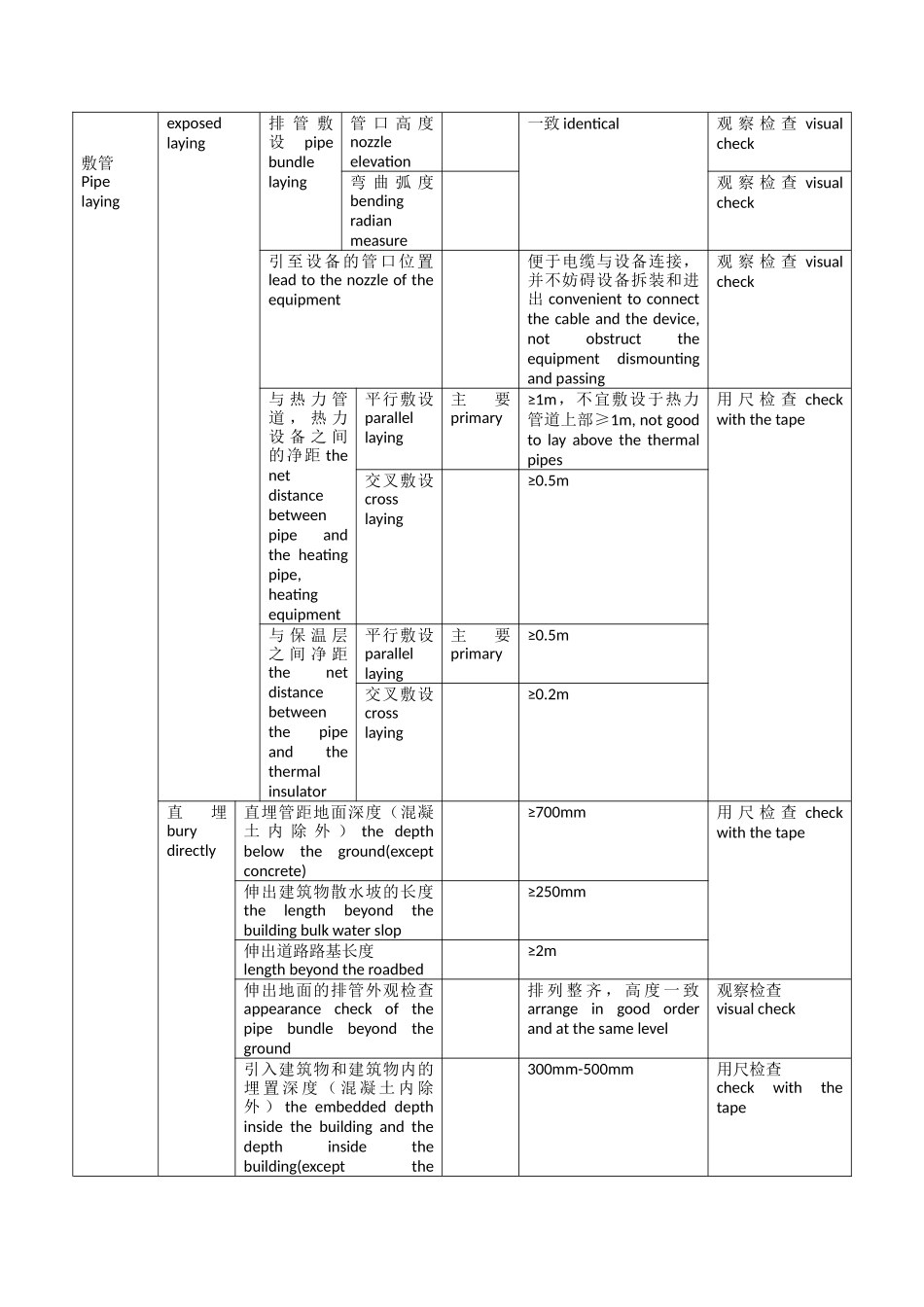

电缆管配置及敷设Cablepipeconfigurationandlaying工序Process检验项目Checkitems性质Property质量标准Qualitystandard检验方法和器具Inspectionmethodandinstrument电缆管制作Cablepipefabrication外观检查appearanceinspection金属管metalpipe内表面Innersurface光滑,无毛刺smooth,noburrs观察检查visualcheck外表面Outsidesurface无穿孔、裂缝、显著的凹凸不平及锈蚀nohole,crack,obviousunevennessorrust塑料管plasticpipe敷设温度layingtemperature按设计规定asperthedesignstipulation按图纸检查并检查出厂合格证checkasperthedrawingandcheckthefactorycertificate管材强度pipestrength切断口(管口)nozzle光滑smooth观察检查visualcheck弯曲部分bendingsection无裂缝及显著的凹瘪nocrackorobviousconcavity每根电缆管的弯头数No.ofeachpipebendingelbows一般弯头commonelbow≤3个notmorethan3观察检查visualcheck直角弯头rightangleelbow≤2个notmorethan2弯曲半径bendingradius主要primary与所穿电缆弯曲半径匹配suitableforthecablebendingradius用样板检查checkwiththesample电缆管弯扁度cablepipebendingflatnessdegree不大于1/10电缆管外径notbiggerthan1/10ofthecablepipeOD用尺检查checkwiththetape电缆管检查Cablepipeinspection电缆管内径IDofthecablepipe按设计规定,且不小于1.5倍电缆外径asperdesignstipulation,andnotlessthan1.5timesofthecableoutsidediameter用尺检查checkwiththetape管内畅通检查non-obstructioncheck主要primary光滑,无积水,杂物smooth,noseeperorsundries用0.85倍管内径拉线球检查checkwiththebracingwireball(0.85timespipeinsidediameter)路径method按设计规定asperdesignstipulation对照图纸检查checkcomparingwiththedrawings明敷单管敷设singlepipelaying横平竖直horizontalandvertical观察检查visualcheck敷管Pipelayingexposedlaying排管敷设pipebundlelaying管口高度nozzleelevation一致identical观察检查visualcheck弯曲弧度bendingradianmeasure观察检查visualcheck引至设备的管口位置leadtothenozzleoftheequipment便于电缆与设备连接,并不妨碍设备拆装和进出convenienttoconnectthecableandthedevice,notobstructtheequipmentdismountingandpassing观察检查visualcheck与热力管道,热力设备之间的净距thenetdistancebetweenpipeandtheheatingpipe,heatingequipment平行敷设parallellaying主要primary≥1m,不宜敷设于热力管道上部≥1m,notgoodtolayabovethethermalpipes用尺检查checkwiththetape交叉敷设crosslaying≥0.5m与保温层之间净距thenetdistancebetweenthepipeandthethermalinsulator平行敷设parallellaying主要primary≥0.5m交叉敷设crosslaying≥0.2m直埋burydirectly直埋管距地面深度(混凝土内除外)thedepthbelowtheground(exceptconcrete)≥700mm用尺检查checkwiththetape伸出建筑物散水坡的长度thelengthbeyondthebuildingbulkwaterslop≥250mm伸出道路路基长度lengthbeyondtheroadbed≥2m伸出地面的排管外观检查appearancecheckofthepipebundlebeyondtheground排列整齐,高度一致arrangeingoodorderandatthesamelevel观察检查visualcheck引入建筑物和建筑物内的埋置深度(混凝土内除外)theembeddeddepthinsidethebuildingandthedepthinsidethebuilding(exceptthe300mm-500mm用尺检查checkwiththetapeconcrete)电缆管道与其他管道、道路、建筑物之间平行和交叉时的净距theparallelandacrossnetdistancebetweenthecabletrenchandothertrenches,roadsandbuildings主要primary按GB50168—1992表5.4.3规定AsperGB50168—1992Stipulatedinchart5.4.3电缆管连接CablePipeconnection金属管metalpipe套管连接bushingpipeconnection套管长度bushingpipelength1.5D-3D电缆管外径1.5D-3DcablepipeOD用尺检查checkwiththetape外观检查appearancecheck焊接牢固Weldedfirmly观察检查和用镀锌铁丝绑棉纱通入管内检查visualcheckandcheckthroughinsertingthecottonyarntiedgalvanizedironwire丝扣连接管端套丝长...