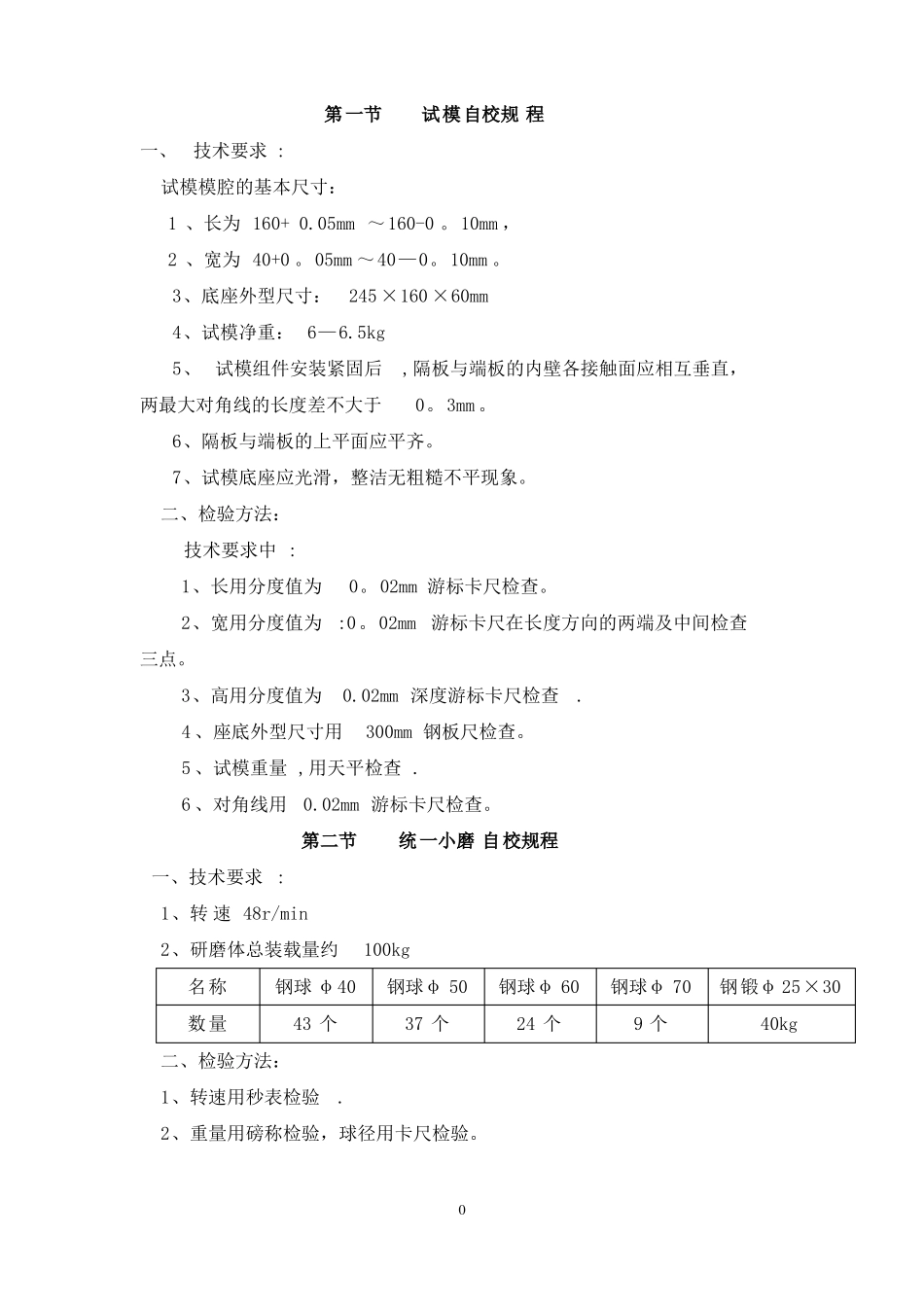

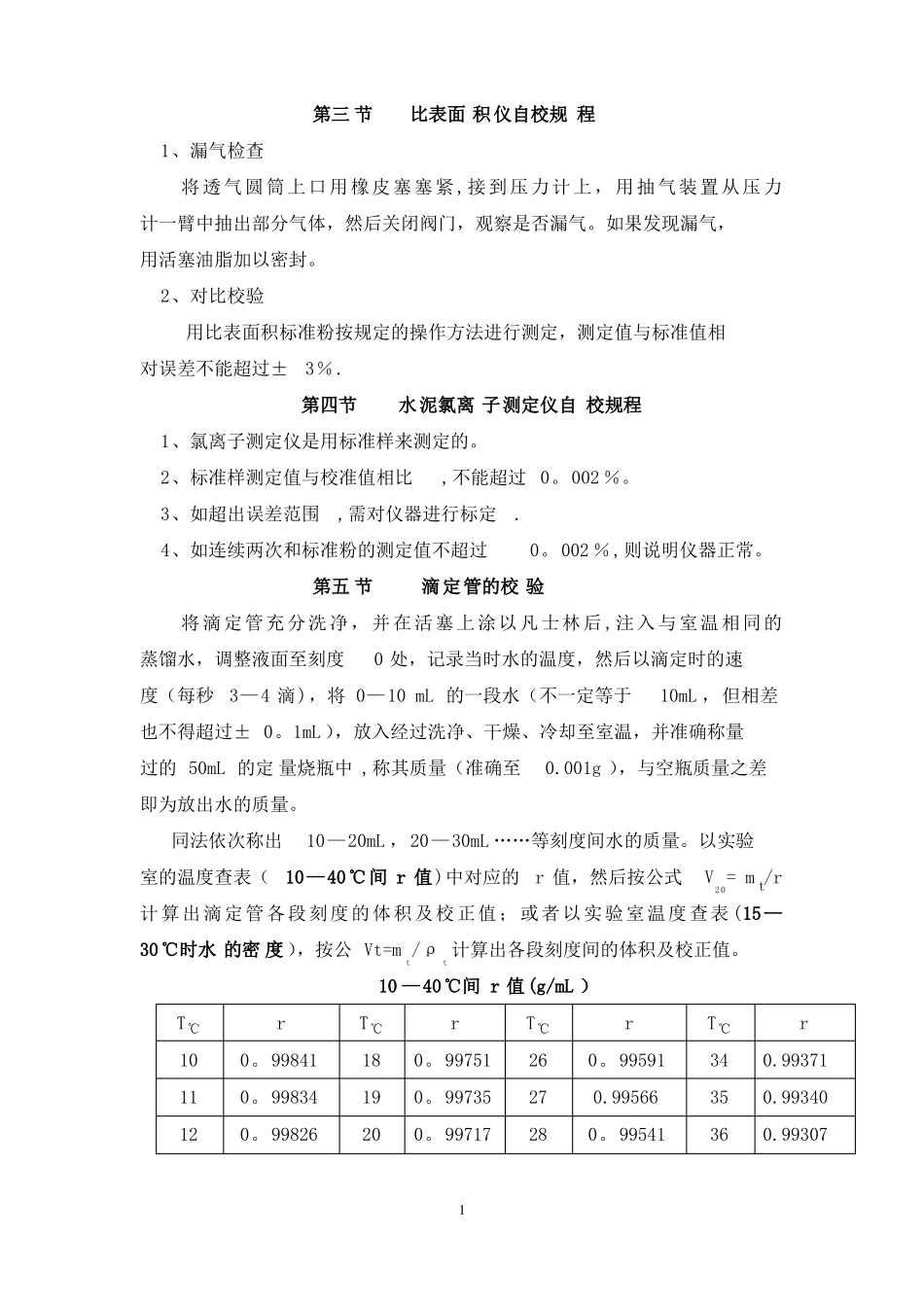

目录第一节试模自校规程······································1第二节统一小磨自校规程··································1第三节比表面积仪自校规程································2第四节水泥氯离子测定仪自校规程··························2第五节滴定管的校验······································2第六节容量瓶的校验······································3第七节移液管的校验······································4第八节胶砂搅拌机的使用、维护和校准···················5第九节胶砂振实台的使用、维护和校准···················5第十节净浆搅拌机的使用、维护和校准···················6第十一节贵重金属的使用和维护···························6第十二节高温炉及其控制器的使用和维护···················7第十三节烘干箱及温度计的使用、维护和校准···············7第十四节压力试验机的使用、维护和校准···················8第十五节抗折试验机的使用、维护和校准···················8第十六节抗压夹具的校准·································8第十七节养护箱的使用、维护和校准·······················9第十八节水泥标准稠度及凝结时间测定仪自校规程···········9第十九节负压筛自校规程·································9第二十节雷氏夹测定仪自校规程··························10第二十一节水泥组份仪自校规程····························10第二十二节钙铁硫测定仪自校规程···························10第二十三节水泥胶砂流动度跳桌自校规程····················101第一节试模自校规程一、技术要求:试模模腔的基本尺寸:1、长为160+0.05mm~160-0。10mm,2、宽为40+0。05mm~40—0。10mm。3、底座外型尺寸:245×160×60mm4、试模净重:6—6.5kg5、试模组件安装紧固后,隔板与端板的内壁各接触面应相互垂直,两最大对角线的长度差不大于0。3mm。6、隔板与端板的上平面应平齐。7、试模底座应光滑,整洁无粗糙不平现象。二、检验方法:技术要求中:1、长用分度值为0。02mm游标卡尺检查。2、宽用分度值为:0。02mm游标卡尺在长度方向的两端及中间检查三点。3、高用分度值为0.02mm深度游标卡尺检查.4、座底外型尺寸用300mm钢板尺检查。5、试模重量,用天平检查.6、对角线用0.02mm游标卡尺检查。第二节统一小磨自校规程一、技术要求:1、转速48r/min2、研磨体总装载量约100kg名称数量钢球φ4043个钢球φ5037个钢球φ6024个钢球φ70钢锻φ25×309个40kg二、检验方法:1、转速用秒表检验.2、重量用磅称检验,球径用卡尺检验。0第三节比表面积仪自校规程1、漏气检查将透气圆筒上口用橡皮塞塞紧,接到压力计上,用抽气装置从压力计一臂中抽出部分气体,然后关闭阀门,观察是否漏气。如果发现漏气,用活塞油脂加以密封。2、对比校验用比表面积标准粉按规定的操作方法进行测定,测定值与标准值相对误差不能超过±3%.第四节水泥氯离子测定仪自校规程1、氯离子测定仪是用标准样来测定的。2、标准样测定值与校准值相比,不能超过0。002%。3、如超出误差范围,需对仪器进行标定.4、如连续两次和标准粉的测定值不超过0。002%,则说明仪器正常。第五节滴定管的校验将滴定管充分洗净,并在活塞上涂以凡士林后,注入与室温相同的蒸馏水,调整液面至刻度0处,记录当时水的温度,然后以滴定时的速度(每秒3—4滴),将0—10mL的一段...